Best Seller Color Coated Sheet/Corrugated Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Application of Best Seller Color Coated Sheet/Corrugated Roofing Sheets:

Construction, the manufacturing of cars, ships,containers and household electric appliances, other industries usage

they are mainly used in construction, light industry, automobile, agriculture, animal husbandry, fishery and commerce, etc industries.

.Manufacture anticorrosion, industrial and civil architecture roof boarding, roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils, etc

.Corrosion resistant parts of cars

.Food storage, meat and aquatic products’ freezing and processing equipment etc;

.The equipments to store and transport materials, and packing implements.

2.Features of Best Seller Color Coated Sheet/Corrugated Roofing Sheets:

* uses hot dip galvanized steel sheet as the base material.

* zinc layer protection, dope on the zinc layer can cover and protect the steel base from corrosion.

* color coated sheet is light, beautiful and has good anti-erosion performancevanized steel coil.

* As a rich experience manufacturer, we provide quality product, competitive price and reliable after-sales service.

3.Surface Finish of Best Seller Color Coated Sheet/Corrugated Roofing Sheets :

Surface finish | Pattern | Application |

Regular spangle | Standard spangles with flower pattern | General uses |

Small spanlge | Small spangles than regular | General painting applications |

Zero spangle | Extremely minimized spangles | Special painting applications |

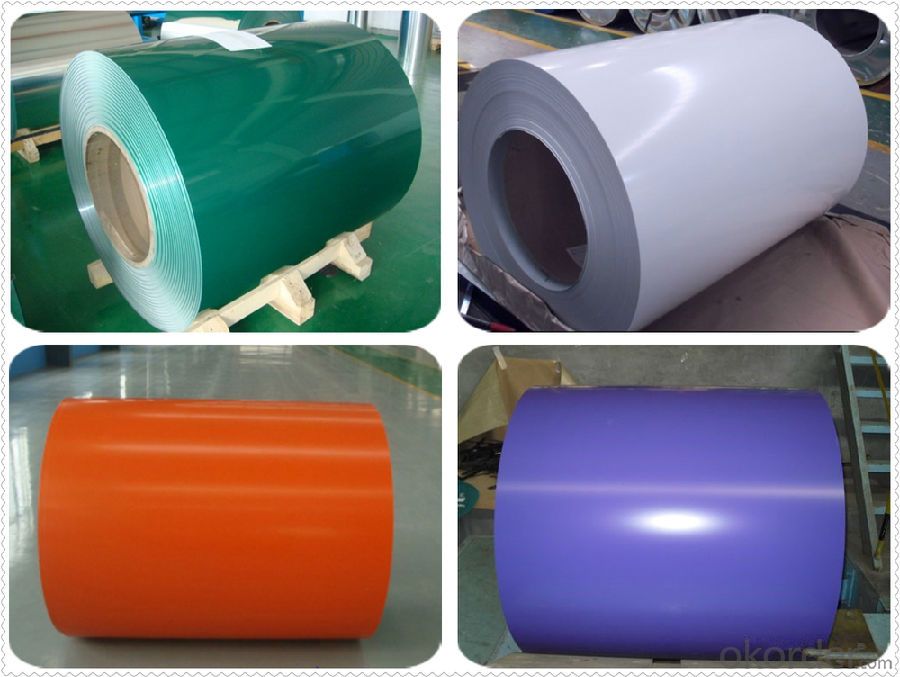

4.Best Seller Color Coated Sheet/Corrugated Roofing Sheets image:

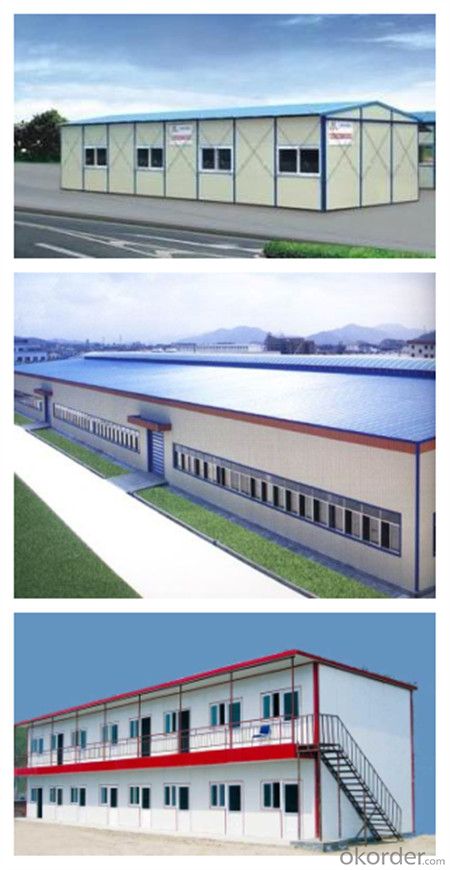

5. APPLICATIONS:

6. PROUDUCTION LINES:

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of color steel coils,is one of the large-scale professional investment steel production bases in China. Annually more than 8000 tons Precision Steel coils to be exported for more than 60 countries.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 10 to 15 working days can be served.

- Q: We just installed a stainless steel electric stove, what is the best way to keep it clean and shiney?

- Contact a sanitary supply company for a product to maintain stainless steel.

- Q: What are the common surface defects found in steel coils?

- Steel coils can have several surface defects commonly found. One prevalent defect is rust or corrosion, which happens when moisture contacts the steel surface and causes oxidation and rust formation. Another defect is scratches or abrasions, occurring during coil handling or transportation. These can vary from small surface scratches to deeper gouges that affect the steel's structural integrity. Surface roughness or unevenness is also possible due to improper rolling or cooling processes during manufacturing, resulting in inconsistent surface texture that affects appearance and performance. Scale is another defect, forming an oxide layer during manufacturing, giving the steel a rough and uneven look. Finally, oil or grease stains may occur during manufacturing or handling, impacting paint or coating adhesion. These common surface defects impact steel quality, appearance, and performance, often requiring cleaning, grinding, or recoating as remedial actions.

- Q: Is steel easier to weld?Which is more brittle/less flexible?

- Note: the easiest way to join steel to aluminum is to drill holes and BOLT them together...... You cannot WELD steel to aluminum.(except using extreme methods like explosion welding......) For all intents and purposes they are dissimilar metals, meaning they will not bond to each other. Also, aluminum has a much lower melting point than steel. It is possible to join steel and aluminum by *Soldering,* using tin/zinc hard solder. This requires a special flux designed exclusively for soldering aluminum though. The heating process is also a bit delicate as you must avoid overheating the joint. I work as a welder and I've only soldered Al three or four times. Steel is easiest to weld by far. If you set the equipment correctly, a six year-old kid can make a good weld on steel. Aluminum requires special equipment and procedures to weld. It's not easy. The brittleness of aluminum depends on it's alloy content. Most of the aluminum that's used today is not pure, rather it's in the form of aluminum ALLOYS which contain either zinc, magnesium, silicon, or manganese. these elements increase the strength dramatically, but also make it much less ductile. Commercially pure (CP) aluminum is very ductile, but it's also rather weak. Pure aluminum is used to make aluminum foil, as it's so soft and ductile it can easily be rolled paper-thin. The best aluminum alloys can come near in strength to mild steel, but weigh less than half as much as steel. Note that steel itself is an alloy of iron and carbon, Carbon increases the strength of iron in the same way that zinc or magnesium increase aluminum's strength. Most of the commonly used aluminum alloys are somewhat more brittle than mild steel, but not greatly so.

- Q: Can steel coils be coated with chrome?

- Yes, steel coils can be coated with chrome.

- Q: How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

- Q: How are steel coils used in the production of steel beams?

- The production of steel beams requires the use of steel coils, which are a vital element in the process. Typically, these coils are created by hot rolling steel strips in a continuous manner. Subsequently, the coils are transported to a steel beam manufacturing facility for further processing. To begin with, the steel coils are unraveled and flattened in order to achieve a flat surface. This step ensures that the dimensions of the beam are uniform and enhances the overall quality. The uncoiling process involves passing the coil through a series of rollers, which gradually unwind the steel strip. Once the steel strip has been unraveled, it is then divided into specific lengths based on the desired size of the steel beams. Generally, this cutting process is executed using automated machinery, which guarantees precision and accuracy. Following that, the cut steel strips are shaped to match the desired profile of the steel beams. This is accomplished through a technique known as roll forming, in which the steel strip is passed through a sequence of rollers that progressively bend and shape it to the required form. The roll forming process enables the creation of various types of steel beams, including I-beams, H-beams, and U-beams, depending on the design and structural requirements. After the roll forming process, the steel beams undergo additional finishing operations, such as straightening, welding, and surface treatment. Straightening ensures that the beams are perfectly aligned and devoid of any deformities. Welding is performed to connect different sections of the beams, ensuring their structural integrity. Finally, the beams are subjected to surface treatment, typically involving methods such as shot blasting or painting, to safeguard against corrosion and enhance their aesthetic appearance. In conclusion, steel coils play a critical role in the production of steel beams, serving as the essential raw material that undergoes uncoiling, cutting, shaping, and further processing. These high-quality steel beams find extensive application in diverse construction projects, encompassing buildings, bridges, and industrial structures, thereby cementing their status as an indispensable component within the construction industry.

- Q: What materials are used to make steel coils?

- Steel coils are primarily made from a material called steel, which is an alloy composed mainly of iron and carbon. The specific type of steel used to make coils depends on the desired properties and applications. Generally, carbon steel is the most common type used, as it offers strength, durability, and versatility. Other alloying elements may be added to enhance certain properties or characteristics of the steel, such as manganese, silicon, nickel, or chromium. The production of steel coils involves melting down the raw materials, refining the molten steel, and then shaping it into coils using specialized equipment and processes.

- Q: What are the common coil packaging materials?

- The common coil packaging materials include stretch film, shrink wrap, steel strapping, and wooden or cardboard cradles.

- Q: What are the different methods of coil leveling?

- The different methods of coil leveling include roller leveling, stretcher leveling, and temper leveling.

- Q: Are steel coils corrosion-resistant?

- Yes, steel coils can be corrosion-resistant depending on the type of steel used and any additional protective coatings applied.

Send your message to us

Best Seller Color Coated Sheet/Corrugated Roofing Sheets/Al-Zn Galvanized Steel Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords