Color steel sheet made by Cina steel company

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32645 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prepainted steel coil construction building material with galvanized color

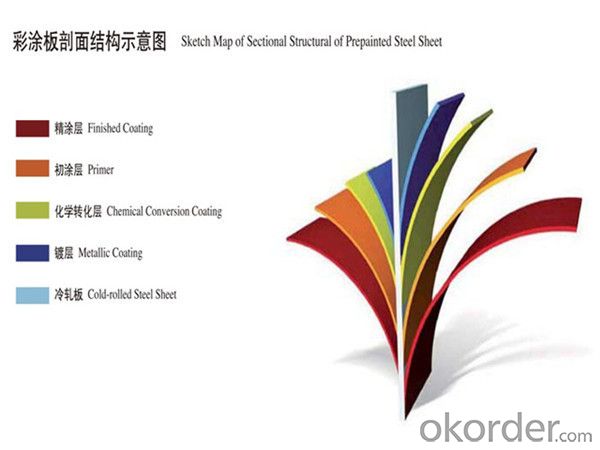

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

2 Better forming ability:

Coating Layer has good bending ability and in high speed forming, it maintains good forming ability and would not cracking or peel off. The coating could be adjusted to meet for different substrate general use, drawing, deep drawing or lock forming, structural use and other purposes.

3 ariable colors:

With different glosses and colors, it displays beautiful appearance that allow for new product designs, diversified creative elements and higher living quality.

.

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

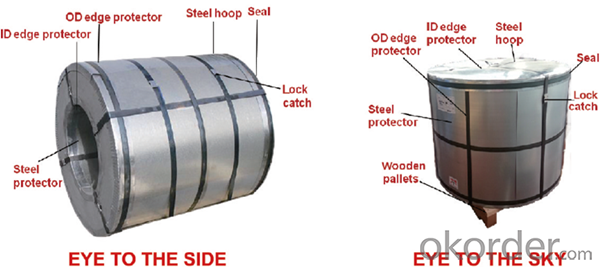

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: What are the different alloying elements used in steel sheets?

- Some of the commonly used alloying elements in steel sheets include carbon, manganese, silicon, chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added in varying quantities to enhance specific properties of the steel, such as strength, hardness, corrosion resistance, and heat resistance.

- Q: How do steel sheets compare to other sheet materials like aluminum or stainless steel?

- Steel sheets have several advantages compared to other sheet materials like aluminum or stainless steel. Firstly, steel sheets are generally stronger and more durable, making them suitable for applications that require high strength and resistance to impact or wear. Additionally, steel sheets have excellent heat resistance, making them suitable for high-temperature environments. Furthermore, steel sheets offer better corrosion resistance than aluminum, while stainless steel sheets provide superior corrosion resistance compared to both steel and aluminum. Finally, steel sheets are generally more cost-effective than stainless steel, making them a popular choice for various industrial and construction applications.

- Q: What are the different quality standards for steel sheets?

- There are several different quality standards for steel sheets, including ASTM (American Society for Testing and Materials), AISI (American Iron and Steel Institute), JIS (Japanese Industrial Standards), and EN (European Norms). These standards outline specific requirements for various aspects of steel sheets, such as chemical composition, mechanical properties, dimensional tolerances, and surface finish. Compliance with these standards ensures that steel sheets meet certain quality and performance criteria and can be used for specific applications in various industries.

- Q: What is the process of embossing on steel sheets?

- Embossing on steel sheets involves the creation of raised or recessed designs on the surface. This technique is commonly used for texture enhancement, aesthetic improvement, or to enhance the mechanical properties of the steel. To begin the embossing process, the steel sheets are prepared. This involves cleaning the surface to remove any dirt, oils, or coatings that could interfere with the embossing. The sheets are then inspected for imperfections or defects that may impact the embossing quality. Once prepared, the steel sheets are placed in an embossing machine consisting of two or more rollers. These rollers have engraved patterns that will be transferred onto the steel sheets. They are typically made of hardened steel or other durable materials. As the steel sheets pass through the embossing machine, pressure is applied to the rollers, causing them to press against the steel surface. This creates a plastic deformation in the sheet, resulting in the desired raised or recessed pattern. The depth and intensity of the embossing can be adjusted by controlling the pressure applied by the rollers. In certain cases, heat may be used during the embossing process to soften the steel sheets, making them more malleable. This allows for deeper and more intricate embossing patterns. The temperature and duration of the heating process depend on the type of steel and desired outcome. After embossing, the steel sheets may undergo additional treatments such as cleaning, coating, or polishing to further enhance their appearance and protect them from corrosion. These finishing steps ensure that the embossed steel sheets meet quality standards and are ready for use. Overall, embossing on steel sheets is a versatile and effective method for adding texture and visual interest. It requires careful preparation, precise machinery, and skilled operators to achieve consistent and high-quality results.

- Q: Can steel sheets be used for electrical conductors or grounding?

- Yes, steel sheets can be used for electrical conductors or grounding, but they have higher resistance compared to copper or aluminum, which are more commonly used for these purposes.

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a commonly used material due to its durability, strength, and ability to provide electromagnetic shielding. It is suitable for protecting electrical components from external factors such as moisture, dust, and impact while also providing a safe and secure environment for the electrical equipment.

- Q: How do steel sheets handle water resistance?

- Steel sheets handle water resistance very well due to their inherent properties. Steel is a non-porous material, meaning it does not absorb water. Additionally, steel sheets are often coated with protective layers, such as galvanized or stainless steel finishes, which provide an extra barrier against water penetration. This makes steel sheets highly resistant to corrosion, rust, and water damage, making them suitable for various applications, including roofing, construction, and marine environments.

- Q: Can steel sheets be used in food processing or pharmaceutical industries?

- Steel sheets are indeed applicable for use in the food processing and pharmaceutical industries. These industries often utilize stainless steel sheets because of their remarkable resistance to corrosion, their durability, and their hygienic properties. Stainless steel, known for being non-reactive and not releasing any harmful substances into food or pharmaceutical products, is frequently employed. Furthermore, its ease of cleaning and maintenance makes it a suitable option for applications that necessitate high levels of cleanliness and hygiene. Moreover, stainless steel sheets are capable of withstanding extreme temperatures and are resistant to impact and abrasion, making them an ideal choice for the food processing and pharmaceutical industries, where stringent quality and safety standards are crucial.

- Q: Can the steel sheets be used for skylights or roof windows?

- Certainly, skylights or roof windows can make use of steel sheets. Steel, being a resilient and robust substance, is capable of enduring diverse weather circumstances, thus rendering it appropriate for such purposes. Moreover, steel sheets may be crafted and tailored to satisfy the particular specifications of skylights or roof windows. By installing them, one can avail oneself of both natural light and ventilation while simultaneously upholding the building's structural integrity. However, it is vital to guarantee adequate insulation and glazing in order to avert any heat loss or gain and to maximize energy efficiency.

- Q: Can steel sheets be used for HVAC systems?

- Yes, steel sheets can be used for HVAC systems. Steel sheets are commonly used in HVAC systems for ductwork fabrication and construction due to their durability, strength, and resistance to corrosion. They are able to withstand high temperatures, making them suitable for heating systems, and can also be used in air conditioning systems for ducts, plenums, and vents.

Send your message to us

Color steel sheet made by Cina steel company

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 32645 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords