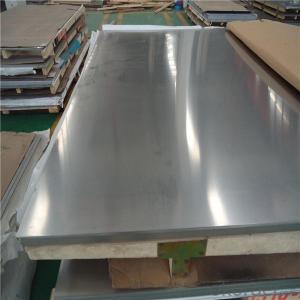

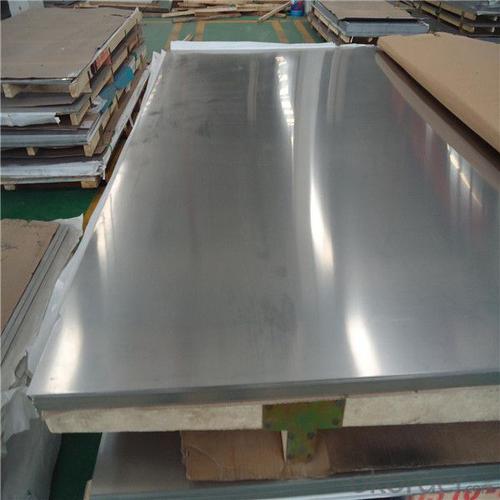

Stainless Steel Sheet CNBM ,Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet

Features Stainless Steel Sheet:

1.Accurate dimension

2.Minimum mainenance

3.Excellent service life

4.Non Corrosive

5.Heat Resistant

Detail information Stainless Steel Sheet:

1. Steel grade: 321

2. Surface: 2B, BA, No. 4, 8K(mirror), HL, embossing, etching. And more than 100 different patterns for your choice.

3. Colors: Golden, rose golden, titanium golden coating, champagne golden, brown, bronze, titanium black, sapphire blue, purple, gray, silver, coffee champagne, jade-green, etc.

4. Thickness: 0.3-120mm

5. Width: 500mm, 1000mm, 1219mm, 1500mm, 1800. And length: Could be cut into any size as per customer's request. Usually our common sizes: 1219mm*2438mm (4*8ft), 1219mm*3048mm (4*10ft) and 1000mm*2000mm.

6. Standard: AISI, SUS, etc.

7. Packing: Standard sea-worthy packing, cover with PVC, and wooden case, or customize package.

8. Application:

Architectural decoration, luxury doors, wall decoration plate, elevators decorating, KTV indoor decoration, metal tank shell, ship building, decoration inside the train, as well as outdoor works, advertising name plate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place, kitchen equipment, light industrial and others.

1. Specifications about stainless steel sheet

Commodity | stainless steel sheet |

Grade | 201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L |

Brand | TISCO ,BAOSTEEL,POSCO,JISCO,LISCO |

Certification | SGS,BV,IQI,TUV,ISO,etc |

Thickness | 0.2mm-150mm |

Width | 1000,1219,1250,1500mm, or as your requirements |

Length | 2000,2438,2500,3000,6000mm, or as your requirements |

Surface | No.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film. |

Standard | ASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc |

Delivery time | 5-7 days after confirming the order |

MOQ | 5 Ton |

Advantages | Showing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste. |

Stainless Steel Sheet

- Q: What is the flatness tolerance for stainless steel sheets?

- The flatness tolerance for stainless steel sheets typically falls within the range of 0.25-0.50% of the sheet thickness.

- Q: What's the difference between 304 stainless steel and 301 stainless steel?

- 301 GB code 1Cr17Ni7; 304 GB mark 0Cr18Ni9

- Q: Can stainless steel sheets be used for roofing applications?

- Yes, stainless steel sheets can be used for roofing applications. Stainless steel is a durable and corrosion-resistant material, making it suitable for use in outdoor environments. It is commonly used in architectural applications, including roofing, due to its strength, longevity, and aesthetic appeal. Stainless steel roofing sheets are available in different thicknesses and profiles, allowing for versatility in design. Additionally, stainless steel is fire-resistant and can withstand extreme weather conditions, making it a reliable choice for roofs.

- Q: Are stainless steel sheets suitable for oil refineries?

- Indeed, oil refineries find stainless steel sheets to be a suitable option. This is due to stainless steel's commendable resistance to corrosion, ability to withstand high temperatures, and durability. These qualities render it highly compatible with the harsh conditions encountered in oil refineries, where the presence of corrosive chemicals, elevated temperatures, and constant exposure to moisture can prove detrimental to alternative materials. Commonly utilized within oil refineries, stainless steel sheets serve various purposes such as storage tanks, pipelines, heat exchangers, and other equipment that necessitate corrosion resistance. Furthermore, the ease of cleaning and maintenance of stainless steel sheets plays a pivotal role in preserving the efficiency and functionality of equipment within oil refineries.

- Q: Can stainless steel sheets be used for hygienic applications?

- Stainless steel sheets are indeed suitable for hygienic applications. The reason lies in its remarkable hygiene properties attributed to the non-porous surface, which effectively resists bacteria, mold, and other microorganisms. Moreover, stainless steel is effortless to clean and maintain, making it perfect for sectors that prioritize cleanliness and hygiene, including the food and beverage industry, healthcare facilities, and pharmaceutical manufacturing. Furthermore, stainless steel exhibits exceptional durability, corrosion resistance, and high-temperature tolerance, rendering it a superb choice for hygienic applications.

- Q: Can stainless steel sheets be used for water tanks?

- Yes, stainless steel sheets can be used for water tanks. Stainless steel is a popular choice for water tanks due to its corrosion-resistant properties. It is highly resistant to rust and can withstand exposure to water and moisture without deteriorating. Stainless steel is also hygienic, as it does not react with water or leach any harmful substances into it. Additionally, stainless steel tanks are durable and long-lasting, making them a reliable option for storing water. Overall, stainless steel sheets are a suitable material for constructing water tanks, providing a safe and reliable storage solution for water.

- Q: How can I classify stainless steel plates?

- The stainless steel plate in accordance with the classification of surface features can be divided into: silver white matte (use does not need to have a surface gloss), bright as a mirror (building materials, kitchen utensils), coarse grinding fine grinding / polishing / intermediate / fine grinding (building materials, kitchen utensils), hairline grinding (buildings, building materials), close to the mirror grinding (art, decoration), mirror grinding (mirror, decorative).

- Q: What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- Using diamond plate stainless steel sheets in industrial flooring offers numerous advantages. Firstly, their exceptional durability and strength make them highly resistant to wear and tear. The diamond pattern on the surface enhances their structural integrity, making them particularly suitable for protecting against damage caused by heavy machinery, equipment, and foot traffic. The stainless steel construction also ensures that the sheets are resistant to corrosion, extending their lifespan and reducing maintenance costs. Secondly, diamond plate stainless steel sheets provide superior slip resistance. The raised diamond pattern on the surface increases traction, making it safer and easier for workers to move around the industrial floor. This is especially important in environments where spills, oils, or other liquids are present, as it helps prevent slip and fall accidents and injuries. Additionally, these sheets are hygienic and easy to clean. The smooth surface and corrosion-resistant properties of stainless steel prevent dirt, grime, and bacteria buildup. This is crucial in industries such as food processing, pharmaceuticals, or healthcare, where maintaining a clean and sanitary environment is of utmost importance. Furthermore, diamond plate stainless steel sheets enhance the overall appearance of the industrial space. The diamond pattern adds a modern and industrial touch, creating a professional and visually appealing environment. Lastly, these sheets are versatile and can be easily customized to meet various industrial flooring requirements. They are available in different sizes, thicknesses, and grades, allowing for flexibility in design and installation. This adaptability makes them suitable for a wide range of applications, including factory floors, warehouses, garages, and outdoor areas. In conclusion, diamond plate stainless steel sheets offer durability, slip resistance, hygiene, aesthetic appeal, and versatility when used in industrial flooring. These advantages make them an excellent choice for ensuring a safe, long-lasting, and visually appealing flooring solution in industrial settings.

- Q: Can stainless steel sheets be used in high-pressure applications?

- Yes, stainless steel sheets can be used in high-pressure applications. Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for withstanding high-pressure environments. It can be used in various industries, such as oil and gas, chemical processing, and power generation, where high-pressure conditions are present.

- Q: What are the benefits of using stainless steel sheets?

- There are several benefits of using stainless steel sheets. Firstly, stainless steel is highly durable and resistant to corrosion, making it suitable for various applications in different environments. Secondly, stainless steel is easy to clean and maintain, making it a hygienic choice for industries such as food processing and medical facilities. Additionally, stainless steel sheets have a sleek and modern appearance, making them aesthetically pleasing for architectural and design purposes. Lastly, stainless steel is recyclable and environmentally friendly, making it a sustainable choice.

Send your message to us

Stainless Steel Sheet CNBM ,Wuxi, China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords