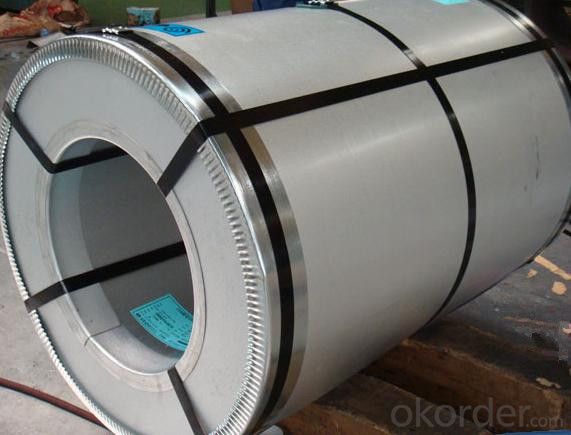

Color Coated Zinc Steel Coil Plate(SC-001)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic Info.

Model NO.:SC-001

Surface Treatment:Coated

Grade:Galvanized or Gavalume

Width:914, 1000, 1200, 1219, 1220, 1250

Treatment:Galvanized or Gavalume

Color:Ral Standard, or Buyer′s Sample Color

Zinc Coating:40-150GSM

Length:up to The Thickness

Base Material:Steel

Lacquer:Top Side15-25 Micro, Back Side 5 Micro

Surface:Passivation Unoiled Free Spangle Passivated

Export Markets:Global

Additional Info.

Trademark:STW or OEM

Packing:Export Seaworthy Packing

Standard:JIS G3312 / CGCC

Production Capacity:20000 Metric Tons/Month

Specifications;

1. Aluzinc coating mass: 30g-275g/sqm

2. Coil weight:4-6 tons per coil

3. Edge treatment: Mill edge or cut edge.

4. Technical treatment: Bright annealed, flatting, cold harden.

5. Surface treatment: Annealed, bright finish, dull/bright finish, slit edge.

6. Spangle: Normal/small/big/zero spangle.

7. Delivery terms: FOB / C&R / CIF

8. Supply Ability: 20000MT/month

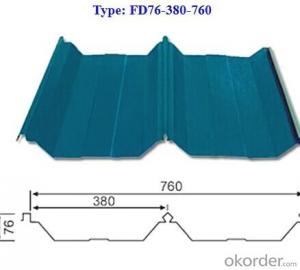

9. Application: The construction industry: The roof structure, keel, grill, Clapboard, ceilings, fire shutter doors, etc; The light industry, the Automobile, agriculture, animal husbandry, fishery, casing of household Electronic application, civilian smoke stack, etc.

10. Delivery time: Within 30 days after the receipt of L/C or Signed the contract or according to customer's requirement.

Special design available according to requirement; Anti-corrosion And high-temperature resistant with black painting; All the production process Are made under the ISO9001: 2000 strictly

Package: Sea worthy Export Packing Standard export and seaworthy packing. (waterproof paper and metal sheet protection with fluted rings at inner and outer edges, 4 eye bands and 4 circumferential bands fasten the coil)

- Q: How are steel coils used in the production of HVAC ductwork?

- Due to their durability and strength, steel coils find widespread use in the production of HVAC ductwork. Galvanized steel is typically used to make these coils, as it offers protection against corrosion and extends the lifespan of the ductwork. To initiate the manufacturing process, the steel coils are unrolled and cut to the desired length. Subsequently, they are passed through a machine that shapes the steel into either a rectangular or round duct form. This shaping process employs various techniques like roll forming or press braking. Once the steel has taken the desired duct shape, it is joined together using different methods such as welding or locking mechanisms. Rectangular ducts are commonly welded, while round ducts often incorporate locking mechanisms like snap locks or Pittsburgh seams. These joining techniques ensure the ductwork is secure and airtight. Following the assembly of the ductwork, additional processes like insulation or lining may be applied. Insulation aids in minimizing heat loss or gain, while lining improves the acoustic properties of the ductwork. These supplementary steps are often undertaken to comply with specific requirements or regulations. In conclusion, steel coils are essential in the production of HVAC ductwork due to their strength, durability, and corrosion protection. Steel's versatility allows for the fabrication of ductwork in various shapes and sizes, making it a popular choice for HVAC systems.

- Q: What are the different types of steel coil handling systems?

- There are several different types of steel coil handling systems, including coil upenders, coil cradles, coil transfer cars, coil tilters, and coil grabbers.

- Q: Is it just because brass is reloadable? But what makes it reloadable? What does brass bring to the equation that the steel cased ammo can't do?

- Brass is slightly softer than annealed steel. Both can be reloaded, once or maybe even twice. But STEEL has a tendency to WORK HARDEN, becoming brittle. Which is why it's used for tools and other applications where work hardening is a plus. It's actually designed to do that. Brass does not work harden, because it is a different sort of metal. That's the main reason.

- Q: What are the common coil thicknesses available for steel coils?

- The available thicknesses for steel coils, which are commonly used in different industries and applications, can vary depending on specific requirements. The range of coil thicknesses for steel typically falls between 0.5mm and 3mm. In lightweight applications or situations where flexibility is necessary, thinner steel coils with thicknesses ranging from 0.5mm to 1.5mm are often preferred. These thinner coils find suitability in automotive body panels, roofing, and general sheet metal fabrication. On the other hand, for applications that demand higher strength and durability, thicker steel coils with thicknesses ranging from 1.5mm to 3mm are frequently employed. These thicker coils are commonly seen in heavy-duty construction, structural components, and industrial equipment manufacturing. It is important to keep in mind that these mentioned ranges are general and can be subject to variation depending on specific project requirements or customer preferences. Steel coil thicknesses can be tailored to meet specific needs, providing greater flexibility across various industries.

- Q: Can steel coils be cut or trimmed after delivery?

- Yes, steel coils can be cut or trimmed after delivery. Steel coils are typically delivered in large sizes and can be easily cut or trimmed to the desired length or shape using various cutting methods such as shearing, slitting, or laser cutting.

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a combination of visual inspections, measurements, and non-destructive testing techniques. These inspections typically involve checking for surface defects, such as cracks, scratches, or corrosion, as well as ensuring the dimensions and weight of the coils meet the required specifications. Non-destructive testing methods, such as ultrasonic or magnetic particle testing, are also used to detect any internal defects that may not be visible to the naked eye. Overall, these comprehensive inspections help ensure that steel coils meet the desired quality standards.

- Q: What are the different types of steel coil surface treatments?

- The different types of steel coil surface treatments include hot-dip galvanizing, electro-galvanizing, organic coating, and pickling and oiling.

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- by on the internet or ppe clothing shops

- Q: in broken steel can you to missions and get things like the dog, you previously didnt do/get in fallout 3?

- I wish you people would put your questions in the right place.

- Q: Question about steel type used in bridges.?

- Do you mean galvanized steel?

Send your message to us

Color Coated Zinc Steel Coil Plate(SC-001)

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords