Steel Plate of Color Coated Gi Corrugation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Details

Basic Info.

Type:Steel Plate

Standard:ASTM, GB, JIS

Certification:ISO, SGS

Surface Treatment:Coated

Technique:Cold Rolled

Application:Ship Plate

Special Use:High-strength Steel Plate

Stock:Stock

MOQ:25 Tons

Material:SGCC,Sgch.Full Hard/Soft

Spangle:Regular/Big/Small/Zero

Zn Coated:60-120G/M2

Width:760-1250 Mm

Length:Under 5 Meter

Bundle Weight:2-3 Tons

Export Markets:South America, Southeast Asia, Africa, Mid East, Eastern Asia

Additional Info.

Packing:Seaworthy Standard Export Package

Standard:SGS, ISO9001

Origin:Boxing County, Shandong Province

HS Code:72107010

Production Capacity:60000 Tons/Year

Product Description

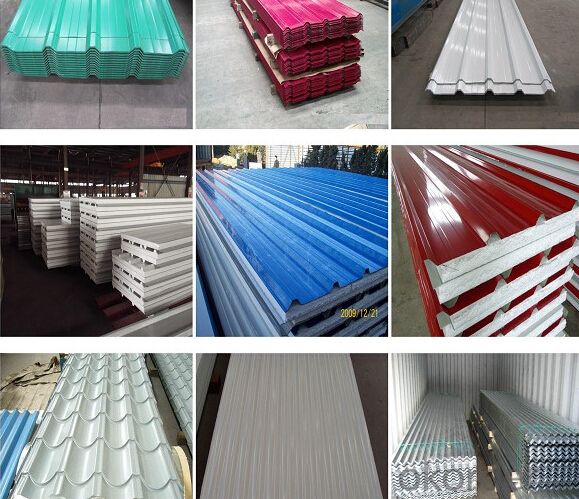

corrugation of hdgi for roofing :

| With the professional produce line, we can manufacture the best quality with competitive price as below: | |

| Thickness: | 0.18-0.80 mm |

| Sheet Width: | 760-1075 mm |

| Bundle weight: | 2.0-3.0 MT |

| Surface finish : | 60-120g/m2 zinc coating and the customers requirment! |

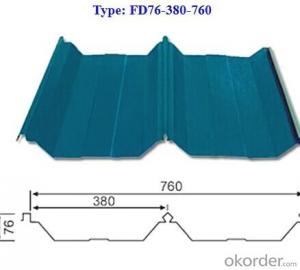

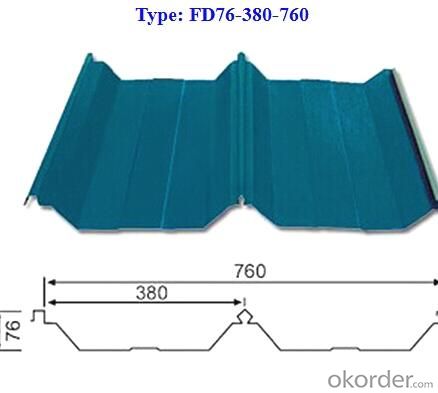

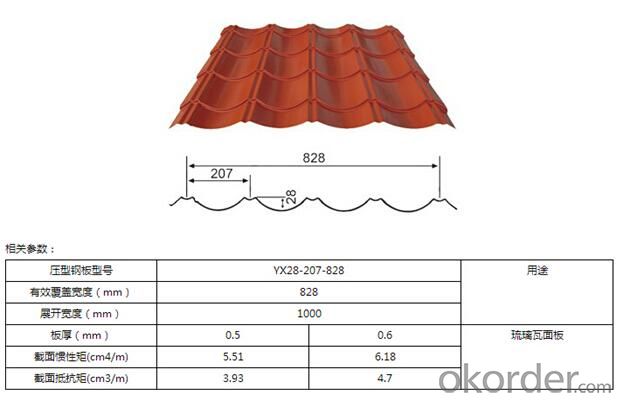

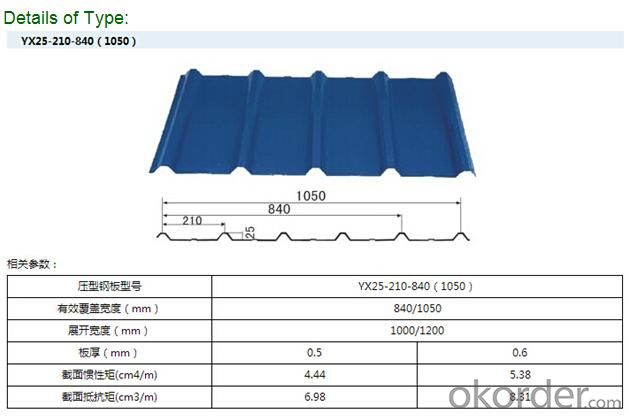

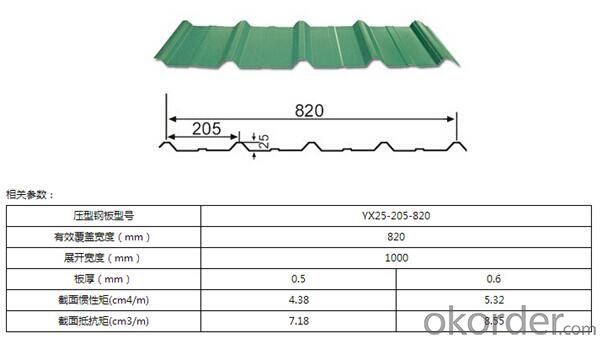

| Type: | YX28-207-828, YX14-63.5-850, YX15-225-900, YX35-125-750 , YX76-380-760, YX12-110-880, YX10-130-910, YX25-205-820/1025, YX25-210-840/1050, YX20-215-860/1075. |

| Standard: | JIS G3302, JIS G3313, ASTM A653, GB/T2518-88, GB11253-89,ASTM A1008- 2000,BS,ETC. |

| Packing: | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet. Used in building material field,Pipe making, furniture making,others |

| MOQ: | 25 tons |

| Delivery times : | 20 days after received T/T or L/C |

| Payment terms : | T/T or L/C ( or as your demand) |

| Supply ability : | 6,000 ton per month |

| County we ever exported: Indonesia, Georgia, Mozambique, Somalia, Myanmar, Argentina,India,Dubai, and Turkmenistan. we can supply you the products you need with most competitive price and high quality. special size and standard can be accepted! | |

Details of Type:

FAQ:

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: Is condensation on steel caused from water being pulled out or is the condensation formed from the air around the steel object?

- Steel contains no water; any water that you see is condensed out of the air.

- Q: What are the factors affecting the price of steel coils?

- The factors affecting the price of steel coils include the cost of raw materials, such as iron ore and coal, as well as energy prices and transportation costs. Other factors include market demand and supply dynamics, global economic conditions, currency exchange rates, government regulations, and tariffs. Additionally, technological advancements, production capacity, and competition within the steel industry can also influence the price of steel coils.

- Q: Steel roofing info. Pros and cons on steel roofing?

- Steel roofing Pro...life of product is much longer then Asphalt shingles....Looks great...multi colors.......Just love the stuff... Cons....More costly then singles at first but since it last longer it is really a better buy.......

- Q: How are steel coils processed for cutting to length or blanking?

- Steel coils are typically processed for cutting to length or blanking through a series of steps. First, the coils are unwound using a machine called an uncoiler, which feeds the steel into the cutting process. Then, the steel passes through a leveler to ensure a flat surface. Next, it enters a shear or blanking process, where the steel is cut into desired lengths or shapes. Finally, the cut pieces are stacked or packaged for further use or distribution.

- Q: Steel Strings on your guitar or nylons? Why?

- Kind of a silly question. I use steel strings on my steel string guitars and nylon strings on my classical guitar. It's not something you have any choice in; steel string guitars must use steel strings and classical guitar must use nylon strings.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless okorder /... on Hot Drink in Stainless Steel Water Bottle.

- Q: How do steel coils contribute to the manufacturing of steel furniture?

- Steel coils play a crucial role in the manufacturing of steel furniture. These coils, which are made of high-quality steel, serve as the primary raw material for the production of various furniture items. Firstly, steel coils are used to create the framework and structure of steel furniture. These coils can be easily cut, shaped, and welded into various shapes and sizes, allowing manufacturers to create sturdy and durable furniture frames. The flexibility of steel coils enables the production of furniture with intricate designs and unique shapes, providing both functional and aesthetic value. Additionally, steel coils are also used in the production of springs for furniture such as sofas and chairs. The elasticity and strength of the steel coils make them ideal for creating comfortable and supportive seating options. These coils are carefully formed and integrated into the furniture, ensuring that the seating surface provides the necessary resilience and flexibility for a comfortable experience. Moreover, steel coils contribute to the overall durability and longevity of steel furniture. Steel is known for its high tensile strength and resistance to wear and tear, making it an excellent choice for furniture that is subjected to heavy use and weight load. The use of steel coils ensures that the furniture can withstand years of regular use without compromising its structural integrity. Furthermore, steel coils are often treated with various finishes and coatings to enhance their appearance and protect them from corrosion. These coatings can be applied to the coils before they are shaped into furniture components, ensuring that the final product maintains its aesthetic appeal and remains resistant to rust and other forms of damage. In conclusion, steel coils are an essential component in the manufacturing of steel furniture. They provide the necessary strength, flexibility, and durability required to create sturdy furniture frames, comfortable seating surfaces, and long-lasting products. Without steel coils, the production of steel furniture would not be possible, and the quality and performance of the final products would be compromised.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts as they provide the raw material required for shaping and forming the shaft. The steel coils are typically cut into specific lengths and then undergo various processes such as heat treatment, machining, and forging to shape them into transmission shafts, which are crucial components in the transmission system of vehicles and machinery.

- Q: What are the common coil defects and their causes?

- Common coil defects can include misshapen coils, coil breaks, and coil slippage. Misshapen coils can be caused by improper winding tension or uneven material thickness. Coil breaks may occur due to excessive tension during winding, inadequate material strength, or improper handling. Coil slippage can result from insufficient binding or improper tension control. These defects can affect the performance and integrity of the coil, leading to potential issues in its functionality.

- Q: What are the guidelines for handling damaged steel coils?

- The guidelines for handling damaged steel coils typically involve inspecting the damage, assessing its severity, and determining if the coil is still safe to handle. If the damage is minor, it may be possible to repair or reinforce the coil. However, if the damage is extensive or compromises the structural integrity of the coil, it is recommended to contact a professional for further evaluation and potential disposal. Additionally, following proper safety protocols, such as wearing protective gear and using equipment suitable for handling heavy loads, is crucial when dealing with damaged steel coils.

Send your message to us

Steel Plate of Color Coated Gi Corrugation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords