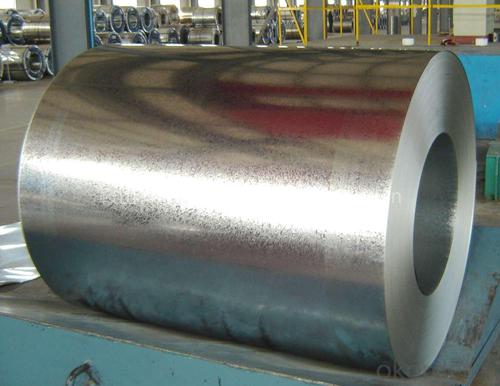

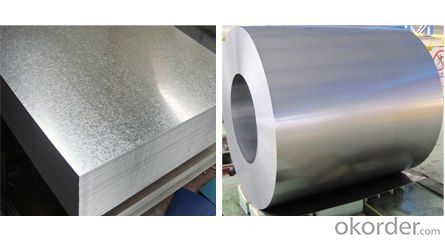

Steel Coil Galvanized Zinc Coating Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Coil Galvanized Zinc Coating Surface

Main Structure of Steel Coil Galvanized :

1.Thickness:0.14-2.5mm

2.Width:600-1250mm

3.Grade:SGCC,JISG3302,DX51D,Q235

4.Zinc Coating:60-275g/m2

5.Coil ID:508mm/610mm

6.Coil weight:3-8ton

Specification of Steel Coil Galvanized:

| Commodity | Steel coil galvanized Zinc coating |

Tech Standard | JIS 3302 / ASTM A653 / EN10143 |

| Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

| Width | 500/650/726/820/914/1000/1200/1219/1220/1250mm |

| Thickness | 0.12-2.5mm (0.14-0.5mm is the most advantage thickness) |

| Type of coating: | galvanized |

| Zinc coating | Z60-275g/m2 |

| Surface treament | chromed / skinpass/ oiled/slightly oiled/ dry/ anti-fingerprint |

| Surface structure: | zero spangle / minimized spangle / regular spangle/ big spangle |

| ID coil | 508mm or 610mm |

| Coil weight | 3-8 MT per coil |

| Package: | Properly packed for ocean freight exportation in 20'containers |

| Application: | Industrial panels, roofing and siding for painting |

| Price terms | FOB,CFR,CIF |

| Payment terms | T/T OR L/C |

| delivery time | 25 days after recepit of deposit |

FAQ

Q: Why should you choose us:

A: 1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Pictures

- Q: I'm currently in an Estimating and Bidding class. I have to estimate two divisions for a multi-million dollar project. The project that I chose is around 6 million dollars and involves constructing a new gas/lighting building. I chose to estimate steel, and my question is, around how much out of the 6 million goes toward just the steel estimate? If it helps, this building is has two floors and is roughly about 100x70 feet. The building not wood construction, but rather steel and brick. How much of that 6 million would go into the steel? I'm not looking for anything exact, just roughly.

- That is a little tough to answer given the details. I will try to answer it as best I can. You can send me a message if you need further help and I can get some more details from you. If it is a 6 million dollar project, that is about $428/sf - (6 million divided by 14,000 sf). $428 is a little bit higher end then say, just a Walmart which is a block and steel box. Assuming you have a concrete slab on the first floor, metal deck on the second floor, with steel beams and open web joists framing, steel columns and steel roof framing with a metal deck roof.... you could be approx 10-15% of the total 6 million. Now, this would include the structural steel, not light gauge steel framing for walls. It sounds like you are looking for structural steel, not metal stud framing. Hopefully this helps, I can check back to this thread later to see if you've had to add any more details.

- Q: What are the factors affecting the lifespan of steel coils?

- There are several factors that can affect the lifespan of steel coils. Firstly, the quality of the steel used in the manufacturing of the coils plays a significant role. High-quality steel with proper composition and metallurgical properties tends to have a longer lifespan compared to lower-quality steel. Secondly, the environment in which the steel coils are stored and used also affects their lifespan. Exposure to extreme temperatures, humidity, and corrosive substances can lead to degradation and corrosion of the coils, reducing their lifespan. Proper storage conditions, such as controlled temperature and humidity levels, can help prolong the lifespan of the coils. Thirdly, the handling and transportation of steel coils can impact their lifespan. Improper handling, such as dropping or mishandling during loading and unloading, can cause physical damage to the coils, leading to premature failure. Similarly, rough transportation conditions, such as excessive vibration or impact, can also contribute to the deterioration of the coils and reduce their lifespan. Furthermore, the maintenance and care of the steel coils also play a role in their lifespan. Regular inspection, cleaning, and maintenance can help identify and address any potential issues before they become major problems. Additionally, applying protective coatings or treatments to the coils can help prevent corrosion and extend their lifespan. Overall, a combination of factors including the quality of the steel, storage conditions, handling and transportation, and maintenance practices all contribute to the lifespan of steel coils. It is essential to consider these factors and take appropriate measures to ensure the longevity of the coils.

- Q: How are steel coils used in the production of automotive wheels?

- Steel coils are used in the production of automotive wheels as they are shaped and molded into rims before being welded or bolted onto the wheel hubs. The steel coils provide the necessary strength and durability required for the wheels to handle the weight and stresses of the vehicle, ensuring a safe and reliable driving experience.

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils differ from regular steel coils in terms of their protective coating. Galvanized steel coils are coated with a layer of zinc, which provides a protective barrier against corrosion and rust. This process, known as galvanization, involves dipping the steel coils into a bath of molten zinc or applying zinc onto the surface through various methods. Regular steel coils, on the other hand, do not have this protective coating, making them more susceptible to corrosion and rust. The zinc layer on galvanized steel coils not only acts as a physical barrier but also provides sacrificial protection, meaning that if the coating gets scratched or damaged, the zinc sacrifices itself to protect the underlying steel from corrosion. This makes galvanized steel coils highly durable and suitable for applications that require resistance to harsh environmental conditions, such as outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: I'm a Hobbyist and want to Build my own axial-flow jet engine,can I use steel as the Turbine blades instead of Titanium which I can't get easily?? What about the other parts I can use for...?!

- You can use steel but alloyed with a big percent of Mn and Cr. Titanium is very good but unfortunately it is expensive. On engines and Turbine blades it is indicate to use High Alloy metals that are resistant to fluage.

- Q: What are the best types of steel for swords

- Don't know too much but I know combat grade katanas are made out of folded carbon-steel. Could also look into industrial steel grading systems if you are looking for something to show off at a martial arts tournament or something.

- Q: How are steel coils inspected for width variations?

- Steel coils are typically inspected for width variations using non-contact laser measurement systems. These systems use lasers to scan the entire surface of the coil and measure the distance between the coil edges at regular intervals. This data is then analyzed to detect any variations in width, allowing for timely adjustments and ensuring the desired specifications are met.

- Q: What are the common methods of welding steel coils?

- The common methods of welding steel coils include shielded metal arc welding (SMAW), gas metal arc welding (GMAW), flux-cored arc welding (FCAW), and submerged arc welding (SAW).

- Q: which cost more: ALLOY, GUNMENTAL OR STAINLESS STEEL. GIVE ME AN IDEA OF THE COST OF EACH.

- Alloy okorder /

- Q: What are the trends and developments in the steel coil industry?

- Over the past few years, the steel coil industry has undergone various trends and developments. These changes have been influenced by different factors, including advancements in technology, shifts in supply and demand, and concerns for the environment. One notable trend in the steel coil industry is the increasing utilization of advanced technologies in production. Automation and robotics have revolutionized the manufacturing process of steel coils, resulting in improved efficiency and quality control. These technologies have also enabled the industry to meet the rising demand for customized steel coils by allowing faster and more precise production. Another trend in the industry is the move towards lightweight and high-strength steel coils. With the increasing need for fuel-efficient vehicles, manufacturers are seeking lighter materials that still possess strength and durability. Steel coil producers are developing innovative products, such as advanced high-strength steels and ultra-high-strength steels, that meet these requirements. These materials offer enhanced performance while reducing the weight of the final product. Concerns for the environment have also spurred developments in the steel coil industry. There is a growing demand for sustainable and eco-friendly steel coils, leading to the adoption of greener manufacturing processes. Steel coil manufacturers are increasingly incorporating recycled materials and implementing energy-efficient technologies to reduce carbon emissions and waste generation. Additionally, there is a focus on improving the recyclability of steel coils to minimize their environmental impact throughout their lifecycle. Furthermore, the steel coil industry is experiencing a shift in the dynamics of supply and demand. Emerging economies, particularly in Asia, are driving the demand for steel coils due to rapid industrialization and urbanization. As a result, there have been increased investments in production capacity in these regions. Conversely, developed economies are witnessing a trend towards consolidation and specialization, with some companies focusing on niche markets or specific applications for steel coils. Overall, the steel coil industry is undergoing significant transformations that are being driven by advancements in technology, changing demand patterns, and environmental concerns. These trends and developments are reshaping the industry, making it more efficient, sustainable, and adaptable to the evolving needs of the market.

Send your message to us

Steel Coil Galvanized Zinc Coating Surface

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords