Color Coated Galvanized Corrugated Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Detailed Specifications:

| Product | Color Coated Galvanized Corrugated Steel Sheet |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application of Color Coated Galvanized Corrugated Steel Sheet

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

.Manufacture anticorrosion, industrial and roof boarding,roof grille.

.Make home appliance’s case, civil chimney, kitchen utensils.

.Corrosion resistant parts of cars.

.Food storage, meat and aquatic products’ freezing and processing equipment.

.The equipments to store and transport materials, and packing implements.

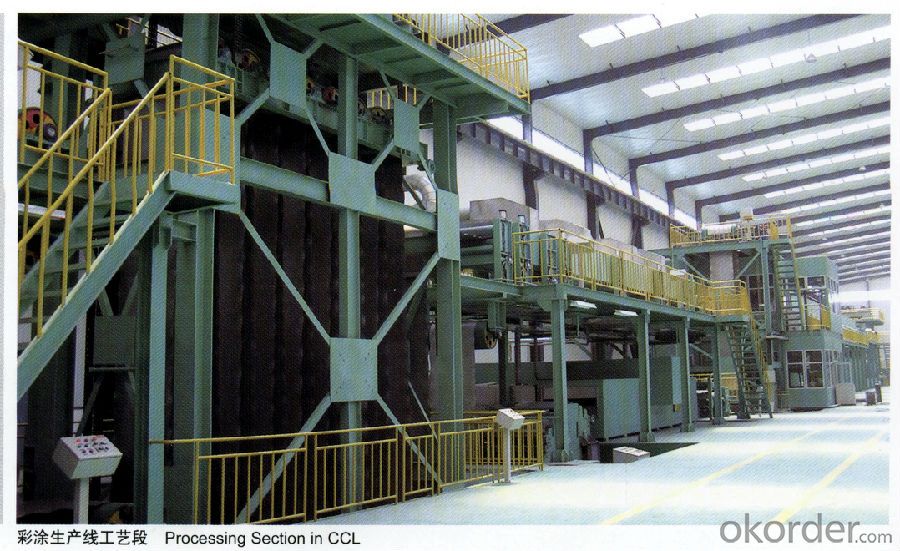

3. Color Coated Galvanized Corrugated Steel Sheet Image:

production Line:

production show:

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: What are the quality standards for steel coil manufacturing?

- The quality standards for steel coil manufacturing include factors such as the grade and composition of the steel, dimensional accuracy, surface finish, mechanical properties, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria for various applications such as construction, automotive, and manufacturing.

- Q: How are steel coils packaged for transportation?

- Steel coils are commonly prepared for transportation through various methods in order to guarantee their secure and safe delivery. The packaging procedure consists of multiple steps that serve to shield the coils from harm during transit and facilitate their handling and loading onto trucks, ships, or trains. To begin with, steel coils are tightly wound and fastened using steel straps or bands to maintain their compactness and prevent unwinding. These straps are typically made from high-strength steel and securely fastened at regular intervals around the coil's circumference. This not only preserves the coil's shape but also prevents any movement while in transit. Following this, the coils are frequently positioned on wooden or steel pallets to establish a stable foundation and enable easy handling with forklifts or cranes. The pallets are usually tailored to fit the dimensions of the coils and designed to withstand the weight and stress of the loaded coils. In order to provide additional protection, steel coils are often enveloped in a layer of protective material such as plastic or paper to shield them from moisture, dust, and other potential contaminants. This wrapping also serves to prevent any scratching or damage to the coils' outer surface. Moreover, to ensure the coils remain secure and avoid shifting during transit, they are oftentimes housed within a steel or wooden crate. These crates offer an extra layer of protection and stability, particularly when transporting larger coils or multiple coils together. Lastly, once the coils are properly packaged, they are typically loaded onto flatbed trucks, shipping containers, or railway cars for transportation. During the loading process, great care is taken to ensure the coils are positioned securely and that weight distribution is balanced to prevent any potential damage or accidents while in transit. In conclusion, steel coils are packaged for transportation by securely binding them with steel straps, placing them on pallets, covering them with protective material, and, if necessary, enclosing them within crates. This packaging procedure serves to safeguard the coils and guarantee their secure and efficient transportation to their intended destination.

- Q: How are steel coils used in the manufacturing of automotive parts?

- Steel coils are used in the manufacturing of automotive parts by being processed and transformed into various components such as body panels, frames, suspension parts, and engine components. The coils are typically flattened, cut, and shaped according to the desired specifications before being incorporated into the assembly line to create the necessary parts for vehicles.

- Q: How are steel coils used in the production of metal furniture?

- Steel coils are used in the production of metal furniture as they are the primary raw material for manufacturing various components such as frames, legs, supports, and brackets. These coils are unrolled and passed through different machinery to shape and cut them into the desired sizes and shapes. The resulting pieces are then welded, joined, or assembled to create the different parts of the furniture. The strength and durability of steel make it an ideal material choice for metal furniture, ensuring sturdy and long-lasting products.

- Q: where can i find information online about steel residential homes that use solar energy?

- Steel okorder

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: I have two guitars, a nylon stringed classical, and a steel stringed acoustic, I find the nylon strings easier to play, but doesn't have as good of sound as the steel stringed, and when I play with the steel strings, it really hurts my fingers, and if I play just a little bit, it feels like the high e string is going to cut my finger. Are the strings too high? What can I do to make the steel strings easier to play?

- find an online tuner and tune the strings to the tuning you want. trust me, guitar hurts your fingers after a while. but your skin gets used to it's, it's what ever.

- Q: How are steel coils used in the production of metal buildings?

- Steel coils are used in the production of metal buildings as they are rolled into sheets and then formed into various structural components such as beams, columns, and roof panels. These coils allow for efficient mass production and provide a high-strength and durable material that ensures the structural integrity of the metal building.

- Q: What is the lifespan of a steel coil?

- The lifespan of a steel coil can vary depending on various factors such as the quality of the steel, its usage and maintenance. However, on average, a well-maintained steel coil can last anywhere from 10 to 30 years.

- Q: How are steel coils used in the manufacturing of transmission shafts?

- Steel coils are used in the manufacturing of transmission shafts by being converted into cylindrical shapes through a process known as coil winding. These coils are then cut, shaped, and machined to create the desired dimensions and specifications for the transmission shafts. The high strength and durability properties of steel make it an ideal material for transmission shafts, ensuring efficient power transmission and overall performance of the machinery.

Send your message to us

Color Coated Galvanized Corrugated Steel Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords