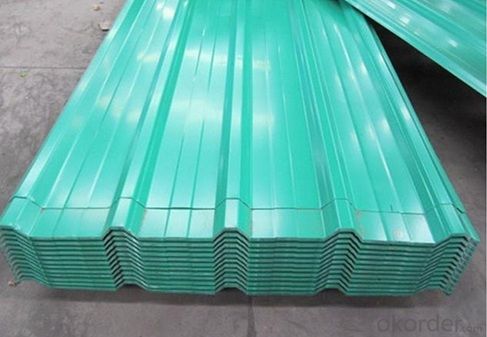

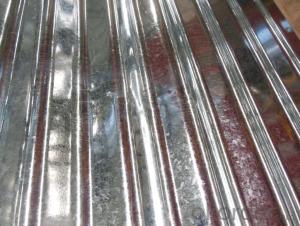

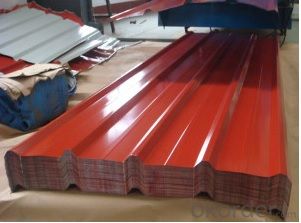

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

COLD ROLLED WAVE GALVANIZED STEEL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What is the difference between a smooth and perforated stainless steel sheet?

- A smooth stainless steel sheet is one that possesses a uniform and flat surface, devoid of any visible texture or patterns. It finds its typical usage in scenarios where a sleek and polished appearance is sought after, like in architectural designs or decorative elements. In contrast, a perforated stainless steel sheet is characterized by the presence of small or large holes that have been punched or drilled into it, resulting in an arrangement of openings on its surface. These openings can take various shapes, such as round, square, or any other, depending on the desired aesthetic or functional requirements. Perforated sheets are commonly employed in situations where ventilation, filtration, or visibility is necessary, such as in industrial equipment, acoustic panels, or safety grating. The primary distinction between a smooth and perforated stainless steel sheet lies in the presence or absence of holes on the surface. While a smooth sheet offers a pristine and uninterrupted appearance, a perforated sheet offers several advantages, including improved airflow, enhanced visibility, and increased sound absorption. Furthermore, the choice between a smooth or perforated sheet hinges on the specific application and the desired functionality. Smooth sheets are ideal for situations that call for a seamless and polished look, while perforated sheets are well-suited for applications that necessitate functionality, such as filtering, screening, or facilitating airflow.

- Q: Are steel sheets suitable for automotive exhaust systems?

- Yes, steel sheets are suitable for automotive exhaust systems. Steel is a commonly used material in the manufacturing of exhaust systems due to its durability, strength, and resistance to high temperatures and corrosion. Automotive exhaust systems are subjected to extreme heat and corrosive gases, and steel sheets are able to withstand these conditions effectively. Additionally, steel sheets can be easily formed and welded, making them suitable for the complex shapes and configurations required in exhaust system components. Overall, steel sheets provide the necessary properties and characteristics required for automotive exhaust systems, making them a suitable choice for this application.

- Q: How do steel sheets perform under heavy loads?

- Steel sheets are highly resilient and perform exceptionally well under heavy loads. Their strong and rigid structure allows them to bear significant weight without deforming or failing. This makes steel sheets an ideal choice for applications requiring load-bearing capabilities, ensuring durability and safety in various industries such as construction, infrastructure, and automotive.

- Q: How are steel sheets protected from damage during handling and transportation?

- Steel sheets are protected from damage during handling and transportation through various methods. One commonly used method is the application of a protective coating on the surface of the steel sheets. This coating can be in the form of a special paint or a layer of zinc, known as galvanization. The protective coating acts as a barrier, preventing any moisture or corrosive elements from reaching the steel sheets and causing damage. In addition to the protective coating, steel sheets are often stacked and secured properly to ensure their stability during transportation. They are usually placed on wooden pallets or in specially designed crates to prevent any direct contact with the ground or other surfaces. This helps minimize the risk of scratches, dents, or other physical damage that may occur during handling or transportation. Furthermore, steel sheets are often packaged and wrapped with materials such as plastic or stretch film to provide an extra layer of protection. This packaging helps safeguard the sheets from dust, dirt, and other contaminants that may affect their quality or appearance. Moreover, steel sheets may be equipped with edge protectors made of plastic or cardboard. These edge protectors prevent any impact or compression damage to the edges of the sheets, which are particularly susceptible to deformation. Finally, proper handling and lifting techniques are essential in safeguarding steel sheets during transportation. Employing specialized equipment such as forklifts or cranes with suitable clamps or magnets ensures that the sheets are lifted and moved without causing any bending or warping. Overall, a combination of protective coatings, proper packaging, and careful handling techniques are employed to safeguard steel sheets from damage during handling and transportation, ensuring their quality and integrity upon arrival at their destination.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets can vary depending on the specific grade and thickness of the steel being used. However, as a general range, the average yield strength of steel sheets typically falls between 250 and 600 megapascals (MPa). It is important to note that different steel grades, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, will have different average yield strengths. Additionally, the thickness of the steel sheet can also impact its yield strength, with thinner sheets generally having higher yield strengths. Therefore, it is crucial to consult the specifications and standards provided by the manufacturer or industry guidelines to determine the specific average yield strength for a particular steel sheet.

- Q: What are the dimensions of steel sheets?

- The dimensions of steel sheets vary depending on the specific application and manufacturer. However, steel sheets typically come in standard sizes ranging from 4 feet by 8 feet (1.2 meters by 2.4 meters) to 6 feet by 10 feet (1.8 meters by 3 meters). Additionally, thicknesses can range from 0.015 inches (0.4 millimeters) to over 1 inch (25 millimeters), again depending on the intended use.

- Q: Can steel sheets be used for flooring?

- Yes, steel sheets can be used for flooring in certain applications. They are commonly used in industrial settings or areas with heavy foot traffic due to their durability and resistance to wear and tear. However, steel sheets may not be suitable for residential or commercial flooring where comfort and aesthetics are more important factors.

- Q: Are steel sheets suitable for cold storage applications?

- Yes, steel sheets are suitable for cold storage applications. Steel is a durable and strong material that can withstand the low temperatures typically required for cold storage. It is resistant to corrosion and does not absorb moisture, making it ideal for keeping the cold air inside the storage area. Additionally, steel sheets can be easily cleaned and sanitized, which is important in maintaining the hygiene and safety of the stored items. Steel also provides excellent insulation properties, helping to maintain a consistent temperature within the cold storage facility. Furthermore, steel sheets can be customized and fabricated to meet the specific size and shape requirements of the cold storage application. Overall, steel sheets are a reliable and practical choice for cold storage applications.

- Q: Are steel sheets suitable for chemical storage applications?

- No, steel sheets are not suitable for chemical storage applications as they can corrode and react with certain chemicals, potentially leading to leaks or contamination.

- Q: Are steel sheets suitable for agricultural applications?

- Yes, steel sheets are suitable for agricultural applications. They are durable, corrosion-resistant, and can withstand harsh weather conditions, making them ideal for various agricultural purposes such as constructing sheds, barns, fences, and storage buildings. Additionally, steel sheets can be easily fabricated and customized to meet specific agricultural needs.

Send your message to us

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords