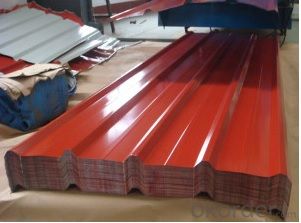

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

COLD ROLLED WAVE GALVANIZED STEEL SHEET

--- Corrosion resistance: Pre-coated steel offers excellent corrosion resistance achived through continuous hot DIP galvanization and corrosion resistant primer/polyester coating. Protection is achieved when zinc and steel are together in the presence of moisture; The zinc protects the steel by galvanic action

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

How long will we receive the goods ?

45days after receiving workable L/C

how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: How do steel strips perform in stamping and forming operations?

- Steel strips generally perform well in stamping and forming operations due to their inherent strength and flexibility. They can easily be shaped and bent into various forms without cracking or breaking. Additionally, steel strips exhibit good dimensional stability, ensuring precise and consistent results during the stamping and forming process.

- Q: What are the different rolling processes for steel strips?

- There are several different rolling processes for steel strips, including hot rolling, cold rolling, and skin pass rolling. Hot rolling involves heating the steel above its recrystallization temperature and then passing it through a series of rollers to reduce its thickness and shape it. Cold rolling, on the other hand, is done at room temperature and involves passing the steel strip through rollers to reduce its thickness and improve its surface finish. Skin pass rolling is a final rolling process that is used to improve the flatness, surface finish, and mechanical properties of the steel strip.

- Q: Can steel strips be used for making precision turned parts?

- Certainly! Precision turned parts can indeed be made using steel strips. These strips possess great versatility and can be machined into a wide range of shapes and sizes, all while maintaining strict tolerances. Consequently, they are highly suitable for precision turning procedures. The exceptional hardness and strength of steel strips render them perfect for applications demanding endurance and resistance to wear, such as precision turned parts utilized in the automotive, aerospace, and manufacturing sectors. Moreover, steel strips can be readily obtained in diverse grades and compositions, thereby facilitating customization to meet specific needs.

- Q: How are steel strips protected against corrosion?

- Steel strips are protected against corrosion through a variety of methods. The most common method is by applying a protective coating on the surface of the steel. This can be done through processes such as galvanizing, where a layer of zinc is applied to the steel. Zinc acts as a sacrificial anode, meaning that it oxidizes before the steel does, thereby protecting it from corrosion. Another method is by applying a layer of paint or enamel on the steel surface. This creates a barrier between the steel and the surrounding environment, preventing moisture and other corrosive elements from coming into contact with the steel. Additionally, steel strips can also be protected through the use of corrosion inhibitors. These are chemicals that are added to the surface of the steel, forming a protective layer that inhibits corrosion. Overall, the goal is to create a barrier or sacrificial layer that prevents the steel from being exposed to corrosive elements, thus extending its lifespan and maintaining its structural integrity.

- Q: How are steel strips used in the production of tools?

- Steel strips are an essential component in the production of tools due to their high strength, durability, and versatility. These strips are primarily used in the manufacturing process to create various types of cutting tools, such as saw blades, drill bits, and knives. One of the main applications of steel strips in tool production is as the raw material for the tool's cutting edge. The strips are carefully shaped and sharpened to create a precise cutting surface that can effectively cut through different materials. The hardness and toughness of steel strips make them ideal for this purpose, as they can withstand the high forces and pressures exerted during the cutting process without deforming or breaking. Additionally, steel strips are used in the production of tool components that require high strength and rigidity. For example, they are commonly used in the construction of tool handles or frames, providing the necessary strength and stability for the tool to be used effectively. Due to their malleability, the strips can be easily shaped or bent to fit the desired design and ensure an ergonomic grip for the user. Moreover, steel strips are often used in the production of specialty tools, such as measuring instruments or precision engineering tools. These tools require high precision and accuracy, and steel strips can be precisely machined and calibrated to meet these requirements. The dimensional stability and uniformity of steel strips make them suitable for creating tools with consistent and reliable performance. In conclusion, steel strips play a crucial role in the production of tools by providing the necessary strength, durability, and versatility required by various cutting tools and tool components. The use of steel strips ensures the production of tools that are robust, reliable, and capable of performing a wide range of tasks in different industries and applications.

- Q: How do steel strips contribute to weight reduction in products?

- Steel strips contribute to weight reduction in products by providing a lightweight yet strong material option. The thin and narrow design of steel strips allows for the reduction of excess weight without compromising on structural integrity. This makes them ideal for various applications where weight reduction is crucial, such as in automotive and aerospace industries.

- Q: Are steel strips used in the production of kitchen utensils?

- Yes, steel strips are commonly used in the production of kitchen utensils due to their durability and corrosion resistance.

- Q: Can steel strips be used in construction applications?

- Yes, steel strips can be used in construction applications. Steel strips are versatile and can be used for various purposes in construction. They are commonly used for framing and structural support, such as in the construction of walls, roofs, and floors. Steel strips are also used in the fabrication of beams, columns, and trusses, providing strength and stability to the structure. Additionally, steel strips can be used for cladding and siding, as they offer durability, weather resistance, and an attractive appearance. Furthermore, steel strips can be easily customized and cut to the desired length, making them suitable for a wide range of construction applications. Overall, steel strips are a popular choice in the construction industry due to their strength, versatility, and ability to enhance the overall structural integrity of a building.

- Q: What are the safety precautions when handling steel strips?

- When handling steel strips, it is important to follow several safety precautions. Firstly, always wear appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to protect against cuts, impacts, and flying debris. Secondly, ensure that the work area is well-lit and free from clutter or obstructions to prevent accidents. When lifting or moving steel strips, use proper lifting techniques and equipment like cranes, forklifts, or lifting straps to avoid strain or injury. Additionally, be aware of the sharp edges and weight of the steel strips and handle them with care to prevent cuts or crushing injuries. Finally, store steel strips in a secure manner to prevent them from falling or causing hazards.

- Q: How do steel strips contribute to reducing product assembly time in various applications?

- The inherent properties and characteristics of steel strips make them a valuable asset in reducing product assembly time in various applications. To begin with, the high strength and durability of steel strips make them ideal for manufacturing processes that require precise and accurate assembly. The robustness of components made from steel strips ensures that they can endure the challenges of the assembly process without sustaining any damage or deformation. Consequently, the need for time-consuming tasks such as repairing or replacing damaged components is eliminated, resulting in a reduction in assembly time. Furthermore, steel strips offer the advantage of easy customization and fabrication into different shapes and sizes, allowing them to adapt to various assembly requirements. This adaptability enables manufacturers to create components that fit seamlessly together, minimizing the time spent on adjusting or modifying parts during the assembly process. Additionally, the ability to customize steel strips facilitates the creation of complex and intricate designs, further reducing the number of components needed for assembly and streamlining the overall process. Another significant benefit of steel strips lies in their high precision and consistency in terms of dimensions and tolerances. This ensures that components produced from steel strips align accurately during assembly, reducing the time required for aligning and adjusting parts. The consistent dimensions also facilitate automated assembly processes, whereby machines can handle and position the components with precision, reducing human labor and assembly time. Additionally, steel strips often come with various surface finishes such as galvanized or coated, providing protection against corrosion and wear and tear. This ensures that components made from steel strips have a longer lifespan, reducing the need for frequent replacements or repairs. Consequently, assembly time is reduced as components can be assembled and integrated more efficiently and reliably. In conclusion, steel strips significantly contribute to reducing product assembly time in various applications due to their high strength, flexibility, precision, and durability. These properties enable faster and more efficient assembly processes by minimizing the need for adjustments, repairs, and replacements. Additionally, they facilitate automation and ensure the longevity of components.

Send your message to us

COLD ROLLED WAVE GALVANIZED STEEL SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords