Aluminum Lithium Alloys Cold Rolled Steel Sheets Directly Wholesale from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

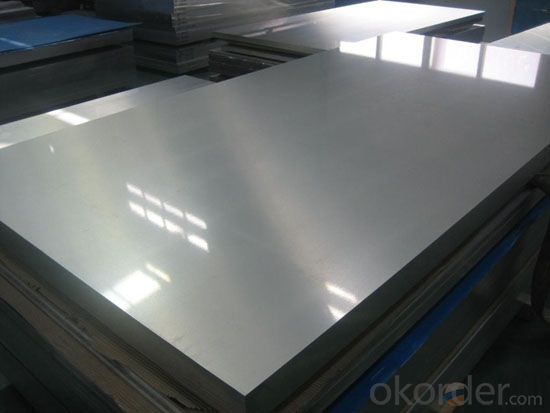

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: What is the hardness rating of 101 aluminum sheets?

- The hardness rating of 101 aluminum sheets can vary depending on several factors, such as the alloy composition, heat treatment, and manufacturing processes. However, in general, aluminum alloys are known for their relatively low hardness compared to other metals. The Rockwell hardness scale is commonly used to measure the hardness of metals, but it is not typically applied to aluminum. Instead, the Brinell or Vickers hardness tests are more commonly used for aluminum alloys. Without specific information about the alloy composition and any specific heat treatment applied to the 101 aluminum sheets, it is difficult to provide an exact hardness rating. Therefore, it is recommended to consult the manufacturer or supplier of the specific 101 aluminum sheets for accurate hardness information.

- Q: What are the dimensions of 101 aluminum sheets?

- The dimensions of 101 aluminum sheets can vary depending on the specific requirements or specifications. Generally, aluminum sheets come in standard sizes and thicknesses, such as 4 feet by 8 feet or 3 feet by 10 feet, with thicknesses ranging from 0.02 inches to 0.25 inches. It is important to note that custom sizes and thicknesses can also be obtained based on individual needs and preferences.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a popular material for balcony railings due to its lightweight nature, durability, and resistance to corrosion. It is a versatile material that can be easily formed into different shapes and designs, making it suitable for various architectural styles. Additionally, aluminum railings require minimal maintenance and can withstand harsh weather conditions, making them a practical and long-lasting choice for balcony railings.

- Q: This question asks for a comparison of aluminum sheets with other common materials used in building insulation, focusing on their properties and performance.

- <p>Aluminum sheets are lightweight and have excellent thermal conductivity, which can be both an advantage and a disadvantage in insulation. They reflect heat well, making them useful in radiant barrier applications, but they are poor insulators as they do not trap heat. In contrast, materials like fiberglass, cellulose, and mineral wool have lower thermal conductivity and are more effective at reducing heat transfer. These materials are better at insulating as they trap air, which is a poor conductor of heat. Foam insulation, such as polyurethane and polystyrene, also offers good thermal resistance due to their closed-cell structure. Overall, aluminum sheets are not typically used as primary insulation but can be effective in specific applications where heat reflection is desired.</p>

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling, where a large ingot of aluminum is heated and passed through a series of rollers to reduce its thickness and increase its length. This continuous rolling process is repeated until the desired thickness is achieved, and the aluminum sheet is then cut into various sizes and shapes.

- Q: Can the aluminum sheets be used for manufacturing heat sinks?

- Yes, aluminum sheets can be used for manufacturing heat sinks.

- Q: Is it possible to use aluminum sheets for roofing purposes?

- <p>Yes, aluminum sheets can be used as roofing materials. They are known for their durability, lightweight, and resistance to corrosion. Aluminum is also recyclable and can be coated with various finishes to enhance its appearance and performance. It is a popular choice for both residential and commercial roofing due to its low maintenance requirements and long lifespan.</p>

- Q: How do aluminum sheets perform in terms of weldability?

- The weldability of aluminum sheets is generally good because of their low melting point and excellent thermal conductivity. Various techniques, such as TIG welding, MIG welding, or spot welding, can be used to weld aluminum sheets. However, there are a few factors that can affect the weldability of aluminum sheets. First, it is necessary to ensure that the surface of the aluminum sheet is clean and free from contaminants like oil, grease, or oxide layers. These contaminants can have a negative impact on the weld quality. Therefore, it is crucial to clean and prepare the surfaces to be welded properly. Second, aluminum sheets have a high thermal conductivity, which means that heat dissipates quickly. This can make it difficult to control the temperature during the welding process. To ensure a successful weld, it is important to have a skilled and experienced welder who can adjust the welding parameters accordingly. Lastly, aluminum sheets have a high coefficient of thermal expansion, which can result in distortion or warping during welding. To minimize these issues, techniques such as tack welding or clamping may be used to hold the sheets in position. In conclusion, aluminum sheets generally have good weldability due to their low melting point and excellent thermal conductivity. However, achieving high-quality welds and avoiding potential issues like contamination, distortion, or warping requires proper surface preparation, skilled welding techniques, and careful temperature control.

- Q: How much weight/people can a 12ft aluminum boat hold?and if anyone knows how much weight can a 6.5hp motor push around

- 12 Ft Aluminum Boats

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

Send your message to us

Aluminum Lithium Alloys Cold Rolled Steel Sheets Directly Wholesale from China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords