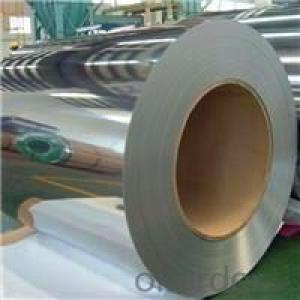

Cold rolled steel sheets/coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Name | Cold Rolled Sheet Coil |

Material | SPCC/SPCD/SPCE/DC01/ST12/ ST14/SPCD/DC03/DC04 ect. |

Grade Standard | JIS G3302, EN10142, ASTM653, ASTM95 |

Thickness | 0.15-3.5mm |

Width | 600mm-1500mm |

Coil ID | 508-610mm |

Coil OD | max 1500mm |

Weight | 3-10 Tons |

Tolerance | Thickness tolerance:+/-0.02mm; Width tolerance:+/-5mm |

Surface | No-skin passed or Skin passed, Tensile leveled |

Surface Treatment | Chromate/Unchromate passivation, fingerprint resistant treatment, oiled/unoiled |

Annual Output | 350,000MT |

Application | Construction, hardware, home applicances, interior decoration |

General Application of Cold Rolled Steel Coil:

Classification | Designation | Characteristics | Main applications |

Commercial quality | SPCC SPCCT | Commercial quality suitable for bending fabrication and simple forming; this is the type in greatest demand. | Refrigerators, cabinets, power distribution baords and drums. |

Drawing quality | SPCD | Drawing quality second only to that of SPCEN. Excellent uniformity. | Automobile floor and roof panels. |

Deep-drawing quality | SPCE SPCF | Deep-drawing quality.With metallurgically controlled grain size, it retains its beautiful finish even after being deep-drawn. | Automobile fenders and quarter panels |

Extra deep-drawing quality | SPCG | Extra-low-carbon steel sheets with highest workability | Automobile internal panels and deep-drawn parts |

- Q: Want to get stainless steel sink. I want quality, durability, quiet, etc. Any suggestions??

- Yes, it’s a good idea to look for the best brand of stainless steel sink as it is used in various purposes regularly. Top brand of stainless steel is naturally longer lasting and capable of bearing lot of pressure then normal stainless steel sink. You must see top brands as well as their prices before buying any.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Barkeeper's Friend is the bomb for a metal and fiberglass cleaner, if it can be removed, it will remove it. I have no clue what it is thats on there.

- Q: I just bought some cheap earrings from this beauty supply store but they said surgical steel So will they prevent my ears from bleeding / infection ?

- Surgical steel is a grade of steel often used in medical appliances like tweezers, forceps, etc. It's generally non-reactive and considered very safe. It doesn't contain any special properties against infection--you still have to observe basic hygiene and clean your piercings properly--but most people can wear surgical steel earrings without a problem. However, if you have a contact allergy to base metals like nickel, surgical steel may cause redness or irritation because of the metals used in it. If cheap rings or necklaces make your skin break out in a rash you should NOT wear surgical steel.

- Q: Describe and explain how the differences in the properties of the thee main types of steel allow them to be used in different ways. I have some chemistry homework due in for tomorrow (yes I know i left it a bit late but I really don't like chemistry) and I would love it if I could actually at least pretend to my teacher that I know what she's on about this lesson because honestly, I really don't know what she spends so long telling us all. Any help would be appreciated and points for the best answer!

- TYPES OF STEEL: CARBON STEEL ============= Steels containing 0.2% C to 1.5% C are known as carbon steel. They are of three types. Low Carbon Steel It contains 0.2% carbon. Uses: Sheets, wires, pipes. Mild Carbon Steel It contains 0.3% to 0.7% carbon. Uses: Rails, boilers, plates, axles, structures. High Carbon Steel It contains 0.7% to 1.5% carbon. Uses: Surgical instruments, razor blades, cutlery, spring. STAINLESS STEEL =============== It contains 14% to 18% chromium and 7% to 9% nickel. Uses: Car accessories, watch case, utensils, cutlery. ALLOY STEEL ============= There are three types of alloy steel. Mn-Steel It contains 10%-18% Mn. Uses: Rail tracks, armor plate, safe. Si-Steel It contains 1% to 5% Si. Uses: Permanent magnet. Ni-Steel It contains 2% to 4% Ni. Uses: Machine components, Gear, shaft, cable. :) Ref. www.google .in/search?q=wikiso...

- Q: What is the difference between cold rolled strip and cold rolled steel coil?

- Cold rolled steel strip: the width is below 900mm! Cold rolled steel coil: the width is above 1000mm! Materials and purposes are not very different, basically the same!

- Q: How can steel coils be recycled?

- Steel coils can be recycled by first removing any non-steel materials attached to them, such as plastic or rubber. The coils are then shredded into smaller pieces and sent to a steel mill, where they are melted down and transformed into new steel products. This process helps conserve natural resources, reduces energy consumption, and minimizes waste.

- Q: What are the common storage defects in steel coils?

- Common storage defects in steel coils include corrosion, rusting, surface damage (such as scratches or dents), coil slippage or misalignment, coil edge damage, and moisture or water damage. These defects can occur due to improper storage conditions, handling, or exposure to environmental factors. Regular inspection and proper storage practices are essential to prevent these defects and maintain the quality of steel coils.

- Q: How do steel coils contribute to strength and durability in manufacturing?

- Steel coils contribute to strength and durability in manufacturing in several ways. Firstly, steel is an inherently strong material due to its high tensile strength, which allows it to withstand heavy loads and resist deformation. When steel is coiled, it undergoes a process called hot rolling or cold rolling, which further enhances its strength and durability. During hot rolling, the steel is heated to high temperatures and then passed through a series of rollers, which compress and shape it into a coil. This process aligns the grain structure of the steel, making it more uniform and reducing internal stresses. The result is a stronger and more resilient material that can withstand the rigors of manufacturing processes such as bending, stamping, and forming without losing its structural integrity. Cold rolling, on the other hand, involves passing the steel through rollers at room temperature. This process not only increases the strength and hardness of the steel but also improves its surface finish. Cold-rolled steel coils are known for their smooth and uniform appearance, making them ideal for applications where aesthetics are important. Furthermore, steel coils can be coated with various protective layers to enhance their durability. These coatings, such as zinc or polymer-based coatings, act as barriers against corrosion, moisture, and other environmental factors that can weaken the steel. By preventing rust and degradation, these coatings extend the lifespan of steel coils and the products they are used in, making them more durable and cost-effective in the long run. In summary, steel coils contribute to strength and durability in manufacturing by providing a strong and resilient material that can withstand heavy loads and resist deformation. The hot rolling and cold rolling processes further enhance the strength and uniformity of the steel, while protective coatings help to prevent corrosion and extend the lifespan of the coils. Overall, steel coils are essential components in manufacturing that contribute to the strength and durability of a wide range of products.

- Q: How are steel coils used in the production of agricultural fencing?

- Steel coils are used in the production of agricultural fencing as they serve as the primary material for creating strong and durable fence wires. These coils are processed and cut into specific lengths, then woven or welded together to form the fencing panels. The high tensile strength of steel ensures that the fencing can withstand the pressure from animals, weather conditions, and other external factors, making it an ideal choice for securing agricultural areas.

- Q: Search the internet for 'Frost Clipper Knife'. This knife comes in either stainless or carbon steel. I have a friend who has one (stainless steel) and he is very impressed with it, but I have heard that Carbon Steel blades are better? Discuss...

- There are different grades of Carbon Steel. A good grade is much harder than Stainless Steel and will stay sharp longer. It is also many times harder to get an edge on than Stainless Steel. I have had both and prefer the Stainless Steel because eventually the Carbon Blade does get dull, and you will wear out a Whet Stone trying to put the edge back on it. The Stainless Steel holds an edge an acceptable amount of time and is easier to sharpen when the time comes. Putting either knife through a can opener sharpener will ruin the edge and make it almost impossible to put another edge on the knife. Look closely and determine the angel of the bevel, then lay the knife bevel flat on a good whet stone and try to take a thin slice off of the stone. Turn the knife over and do the other side so you keep the edge centered on the blade. Keep turning the knife over and taking thin slices until it is sharp. Dress with a good quality sharpening steel.

Send your message to us

Cold rolled steel sheets/coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords