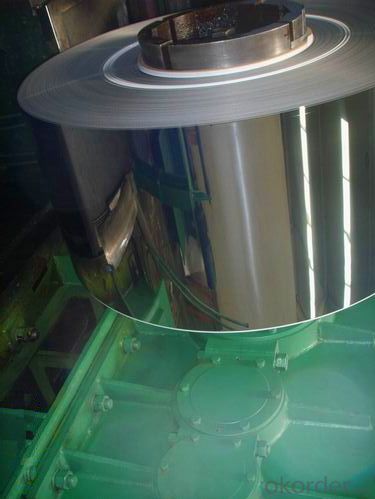

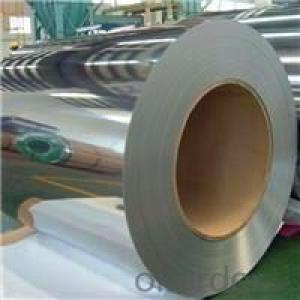

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Grade: | 2B | Standard: | JIS,AISI,GB | Length: | as customers' requested |

| Thickness: | 2.5mm;3.0mm;4.0mm or as required | Width: | 485mm,510mm,600mm or as required | Place of Origin: | Shanxi China (Mainland) |

| Brand Name: | CMAX | Model Number: | 201 | Type: | Coil |

| Application: | Decoration,Boiler Plate,Chemical Industry,Container plate,ship | Certification: | SGS,ISO | Color: | natural color |

| Available Finish: | 2B/BA/8K/No.4/SB/HL | Edge: | slit edge and mill edge | Features: | accurate dimensions |

| Manufacture technology: | cold drawn,pickling, hot rolled and cold rolled | DDQ: | slivery bright surface | Quality: | high quality Hot rolled stainless steel coil 201 |

| Stock: | Always in stock | Item: | Hot rolled stainless steel coil 201 |

Packaging & Delivery

| Packaging Detail: | Standard export packing or as customer's requirement Hot rolled stainless steel coil 201 |

| Delivery Detail: | In 15 days |

Specifications

Hot rolled stainless steel coil 201

Width:485mm,510mm,600mm or as required

Thickness: 2.5mm;3.0mm;4.0mm or as required

Product Description

Stainless steel coil; stainless steel cold rolled coil;201 stainless steel coil; stainless steel coil

A. stainless steel coil

B. with competitive prices and fast delivery

C. High quality

Tisco 201 stainless steel coil

Thickness: 2.5mm;3.0mm;4.0mm or as required

Width: 485mm,510mm,600mm or as required

Length: As required

Material:201

201 stainless steel coil chemical composition

201 stainless steel coil | ||||||||

Grade | Chemical composition | |||||||

C | Si | Mn | P | S | Ni | N | Cr | |

% | % | % | % | % | % | % | % | |

201 | ≤0.15 | ≤0.75 | 5.5~7.50 | ≤0.060 | ≤0.030 | 3.50~5.50 | ≤0.25 | 16.00-18.00 |

201 stainless steel coil physical property

Physical Property | ||||

density | Strength of extension | yield strength | elongation | modulus of elasticity |

g/cm³ | psi | psi | % | psi |

7.93 | 100000-180000 | 50000-15000 | 55-60 | 29000000 |

Item | 201 stainless steel coil |

Technical | Hot rolled and cold rolled |

Standard | ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005,GB/T3280-2007,EN10095-99,JIS4312,etc |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,430 |

Surface | NO.1,2b,4K,8k,HL,mirror finish |

Thickness | 0.3-100mm |

Width | 500-2000mm |

Price term | FOB,CFR,CIF |

Application | Stainless steel coil applies to construction field, ships building industry, petroleum, chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Stainless steel coil can be made according to the customer’s requirements. |

Contact | If you have any question, please feel free to contact me. |

- Q: Can stainless steel strips be used in chemical processing?

- Yes, stainless steel strips can be used in chemical processing. Stainless steel is known for its excellent corrosion resistance, making it suitable for various applications in the chemical industry. It is resistant to many aggressive chemicals, acids, and bases, and can withstand high temperatures and pressures. Stainless steel strips are commonly used in chemical processing equipment, such as reactors, heat exchangers, storage tanks, and piping systems. They provide durability, reliability, and long service life, making them a preferred choice for handling corrosive chemicals and maintaining product purity in chemical processing operations.

- Q: Are stainless steel strips suitable for high-temperature oxidation?

- Yes, stainless steel strips are suitable for high-temperature oxidation. Stainless steel is known for its excellent resistance to oxidation and corrosion, making it an ideal choice for applications that involve high temperatures. The chromium content in stainless steel forms a protective oxide layer on the surface, which prevents further oxidation at elevated temperatures. This oxide layer acts as a barrier against the corrosive effects of oxygen and other elements, thereby ensuring the longevity and durability of stainless steel strips even in high-temperature environments. Additionally, stainless steel alloys with higher levels of chromium, nickel, and other alloying elements exhibit enhanced resistance to oxidation, making them particularly suitable for extremely high-temperature applications.

- Q: What is the impact strength of stainless steel strips?

- The impact strength of stainless steel strips may differ depending on the specific grade and composition of the stainless steel. Stainless steel is widely recognized for its exceptional strength and durability, which includes its resistance to impact. Various industries, including construction, automotive, and aerospace, commonly employ stainless steel strips. These strips encounter different types of impact forces. The robustness and toughness of stainless steel allow it to endure impact and resist deformation, rendering it suitable for applications that necessitate materials with excellent impact resistance. Nevertheless, it is worth noting that the impact strength of stainless steel can also be influenced by factors like strip thickness, applied heat treatment, and any surface coatings or treatments. Furthermore, different grades of stainless steel can exhibit differing impact strengths. To ascertain the precise impact strength of stainless steel strips, it is imperative to refer to specific material data sheets or perform laboratory testing in accordance with relevant industry standards. These tests yield quantitative measurements of impact resistance, determining the material's capability to withstand a specified level of force without fracturing or breaking.

- Q: Can stainless steel strips be used in the chemical processing industry?

- Indeed, the chemical processing industry can make use of stainless steel strips. Renowned for its exceptional resistance to corrosion, stainless steel proves to be a fitting material for the manipulation of diverse chemicals. Its durability knows no bounds, as it endures both heat and high-pressure environments that are customary in chemical processing procedures. Further, the malleability of stainless steel strips permits their effortless transformation into various forms and dimensions, enabling adaptability in the design and fabrication of chemical processing apparatus. All in all, stainless steel strips present themselves as a dependable and effective option for the chemical processing industry.

- Q: Are 111 stainless steel strips suitable for power generation equipment?

- Yes, 111 stainless steel strips can be suitable for power generation equipment. 111 stainless steel is a ferritic stainless steel that contains 11% chromium, which provides good resistance to corrosion and oxidation at high temperatures. This makes it suitable for use in power generation equipment, which often operates at elevated temperatures and is exposed to corrosive environments. Additionally, 111 stainless steel has good mechanical properties, such as high strength and hardness, which are important for withstanding the stresses and strains in power generation equipment. However, the suitability of 111 stainless steel strips for power generation equipment ultimately depends on the specific requirements and conditions of the equipment, so it is important to consult with experts or engineers to ensure the best choice of material.

- Q: How does the price of stainless steel strips compare to other materials?

- The cost of stainless steel strips can fluctuate based on the particular grade and size of the strip, as well as the current state of the market. However, in general, stainless steel strips are typically pricier compared to alternative materials. This is primarily due to the higher expenses associated with production and the distinctive characteristics of stainless steel. Stainless steel is renowned for its exceptional resistance to corrosion, durability, and strength. It is also highly tolerant to heat and physical damage, making it suitable for a wide array of applications in various industries. These superior qualities contribute to the elevated price of stainless steel strips in comparison to other materials. On the other hand, materials such as carbon steel or aluminum are generally more economical. Carbon steel strips are extensively utilized due to their lower production costs and satisfactory strength properties. Aluminum strips, conversely, are lightweight and possess good corrosion resistance, but they are less robust and durable than stainless steel. When contemplating the price of stainless steel strips, it is crucial to assess the specific requirements of the intended use. Although stainless steel may necessitate a higher upfront investment, its long-term advantages, such as an extended lifespan and decreased maintenance costs, can make it a more cost-effective choice in many instances. Ultimately, numerous factors, including market demand, raw material availability, and manufacturing processes, influence the price of stainless steel strips. It is advisable to consult with suppliers or industry experts to obtain accurate and up-to-date pricing information for stainless steel strips and compare it with other materials in order to make an informed decision.

- Q: What are the common methods of cutting stainless steel strips?

- There are several common methods used for cutting stainless steel strips. 1. Shearing: This method involves using a sharp blade to cut through the steel strip. It is often used for thinner strips and provides a clean and accurate cut. Shearing machines or hydraulic shears are commonly used for this process. 2. Laser Cutting: Laser cutting is a highly precise method that uses a focused laser beam to cut through the stainless steel strip. It is suitable for both thin and thick strips and allows for intricate designs and shapes to be cut. Laser cutting machines are often computer-controlled, ensuring accuracy and repeatability. 3. Plasma Cutting: Plasma cutting is another method used for cutting stainless steel strips. It involves using a high-temperature plasma arc to melt through the metal and create a cut. Plasma cutting machines are versatile and can cut through different thicknesses of stainless steel strips. 4. Water Jet Cutting: Water jet cutting uses a high-pressure jet of water mixed with an abrasive material to cut through the stainless steel strip. This method is suitable for various thicknesses and can produce precise cuts without heat-affected zones. Water jet cutting machines are often computer-controlled, making it ideal for complex shapes and designs. 5. Abrasive Cutting: Abrasive cutting methods involve using abrasive discs or wheels to grind through the stainless steel strip. This method is commonly used for thicker strips and can be performed manually or with the help of power tools such as angle grinders. It is important to consider the specific requirements of the project, such as the thickness and design of the stainless steel strip, when choosing the appropriate cutting method. Additionally, safety precautions and proper equipment should always be used when cutting stainless steel strips to ensure a successful and safe outcome.

- Q: Can stainless steel strips be used for pressure vessels?

- Yes, stainless steel strips can be used for pressure vessels. Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high pressure and temperature conditions, making it a suitable material for pressure vessel applications.

- Q: Are stainless steel strips flexible?

- Yes, stainless steel strips can be flexible depending on their thickness and width. Thinner and narrower stainless steel strips tend to be more flexible, while thicker and wider ones may have limited flexibility.

- Q: Are 111 stainless steel strips suitable for heat recovery systems?

- 111 stainless steel strips are not typically suitable for heat recovery systems. Heat recovery systems require materials that can withstand high temperatures and have good heat transfer properties. While stainless steel is known for its corrosion resistance, it may not have the necessary thermal conductivity or tolerance for high temperatures that are crucial for heat recovery systems. It is advisable to consult with a professional engineer or specialist in heat recovery systems to determine the most suitable materials for your specific application.

Send your message to us

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords