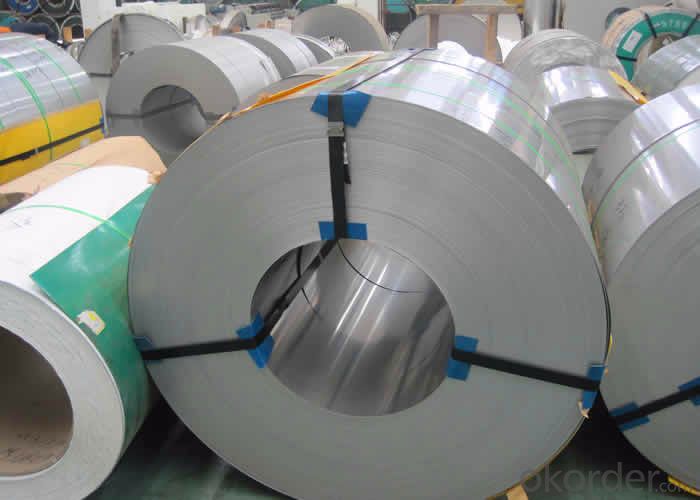

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1,2b 201 stainless steel coil thickness0.2~1.5mm

2.Ensure you quality timely delivery

3.2B finish

4.Tolerance 0.01mm

JMSS cold rolled 2b 304 stainless steel coil

Item Details:

1, 2b 304 stainless steel coil with thickness 0.2~1.5mm

2, Finishing: 2B

3, Width: 15~500mm

4. Tolerance: -0.01mm~0.01mm

Our advantage

1, High quality: Using lastest automated control equipment to ensure 2b 201 stainless steel coil quality, such as AGC system.

2, Best Price: With most automated equipments to cost down.

3, Fast delivery: Since your order placed, ETD will be only 10 days.

4, Best Sevice: We do believe your encouragement is the best support for us.

Shipping information:

1, Payment terms: T/T 30% for depsoit, Balance against the copy of B/L; or L/C at sight

2, ETD: 10-15 days after the receipt of the deposit

3, Ship terms: FOB Ningbo

4, Minimum quantity: 5 tons

Contact and Feedback:

If you are interested in any of 2b 201 stainless steel coil or any question, please feel free to contact us. We will reply you within 24H.

Our Main products:

We are professional manufacturer of 201, 202, 304, 304J1 an 316L stainless steel coil. With 2B finishing, width 15 to 600mm thickness 0.2mm to 1.5mm or width 600mm to 1220mm thickness 0.3mm to 1.5mm.

- Q: Are stainless steel strips suitable for water treatment applications?

- Yes, stainless steel strips are suitable for water treatment applications. Stainless steel is known for its corrosion resistance and durability, making it an ideal material for use in water treatment facilities where exposure to water and chemicals is common. The high strength and resistance to pitting and crevice corrosion of stainless steel make it suitable for various components, such as tanks, pipes, fittings, and filtration systems, ensuring reliable and long-lasting performance in water treatment applications.

- Q: Can stainless steel strips be used in chemical processing plants?

- Yes, stainless steel strips can be used in chemical processing plants. Stainless steel is highly resistant to corrosion, making it suitable for handling various chemicals and corrosive substances in such environments. Its durability, strength, and hygienic properties make it an ideal choice for applications in chemical processing plants.

- Q: Are stainless steel strips suitable for chemical storage tanks?

- Yes, stainless steel strips are suitable for chemical storage tanks. Stainless steel is highly resistant to corrosion, making it ideal for storing chemicals that may be corrosive or reactive. It has excellent strength and durability, ensuring the tank can withstand the pressure and weight of the chemical contents. Additionally, stainless steel is non-porous, preventing the absorption of chemicals and avoiding contamination. It is also easy to clean and maintain, reducing the risk of cross-contamination between different chemicals. Overall, stainless steel strips provide a reliable and long-lasting solution for chemical storage tanks.

- Q: Which material is better, stainless steel or belt?

- Summer is the best with a stainless steel belt, the belt in the summer after the sweat corrosion, there will be an unpleasant smell, easily broken; stainless steel material is relatively good, generally not bad, summer with sweat also nothing, no taste. I hope my answer will be helpful to you!

- Q: Can stainless steel strips be used for automotive exhaust systems?

- Certainly, automotive exhaust systems can utilize stainless steel strips. Stainless steel's exceptional resistance to corrosion, high temperatures, and remarkable strength render it a widely favored option for exhaust systems. The flexibility of stainless steel strips enables convenient fabrication and formation into desired shapes for exhaust components including pipes, mufflers, and catalytic converters. Furthermore, the enduring nature of stainless steel, capable of withstanding extreme temperatures, exposure to diverse chemicals, and environmental elements, ensures its status as a durable and long-lasting material for automotive exhaust systems.

- Q: Can stainless steel strips be used in the food processing conveyors?

- Yes, stainless steel strips can be used in food processing conveyors. Stainless steel is a common material used in the food processing industry due to its corrosion resistance, hygienic properties, and durability. It is suitable for use in conveyors as it can withstand frequent cleaning, exposure to moisture, and high temperatures without degradation or contaminating the food products being processed.

- Q: Can stainless steel strips be used in elevator doors?

- Yes, stainless steel strips can be used in elevator doors. Stainless steel is a popular choice for elevator doors due to its durability, corrosion resistance, and aesthetic appeal. It provides a sleek and modern look while also withstanding the wear and tear associated with elevator usage.

- Q: What are the recommended cleaning and maintenance practices for 111 stainless steel strips?

- To ensure the longevity and appearance of 111 stainless steel strips, there are several recommended practices when it comes to cleaning and maintaining them. To begin with, it is essential to clean the stainless steel strips regularly in order to prevent the accumulation of dirt, grime, and fingerprints. You can use a mild detergent or soap and a warm water solution to effectively clean the surface. However, it is crucial to avoid using abrasive cleaners, harsh chemicals, or steel wool as they can cause damage to the stainless steel. For stubborn stains or residue, it is advisable to utilize a non-abrasive cleaner specifically designed for stainless steel. It is important to carefully follow the instructions provided by the manufacturer while using these cleaners and avoid contact with other surfaces. Once the cleaning is done, it is recommended to thoroughly rinse the stainless steel strips with clean water and dry them using a soft cloth or towel. This will prevent any water spots or streaks from forming on the surface. In terms of maintenance, it is advisable to regularly inspect the stainless steel strips for any signs of damage, such as scratches or dents. If any damage is discovered, it should be attended to promptly to prevent further deterioration. Furthermore, it is crucial to avoid subjecting the stainless steel strips to extreme temperatures or prolonged exposure to acidic substances as they can result in discoloration or corrosion. Additionally, it is recommended to refrain from using sharp objects or abrasive materials on the surface to prevent scratches. Lastly, you can apply a protective coating or polish specifically designed for stainless steel to enhance its shine and provide an additional layer of protection. It is important to carefully follow the instructions provided by the manufacturer while applying these products. By adhering to these recommended cleaning and maintenance practices, the 111 stainless steel strips can maintain their optimal condition, ensuring their durability and visual appeal in the long run.

- Q: Are stainless steel strips available in different widths?

- Indeed, diverse widths of stainless steel strips can be obtained. These strips find widespread usage in multiple sectors, namely construction, automotive, and manufacturing. They are offered in a wide array of widths, catering to distinct project specifications. The width choices encompass slender strips, typically measuring approximately 0.5 inches or less, as well as broader strips that can extend to several inches or even more. The provision of various widths facilitates enhanced adaptability in the design and construction of diverse applications.

- Q: Can stainless steel strips be used in the automotive exhaust system?

- Yes, stainless steel strips can be used in the automotive exhaust system. Stainless steel is a durable and corrosion-resistant material, making it suitable for withstanding the high temperatures and harsh conditions of the exhaust system. It provides excellent resistance to rust and corrosion, ensuring longevity and reliability in automotive applications.

Send your message to us

201 SERIOUS COLD ROLLED STAINLESS STEEL COILS/SHEETS

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords