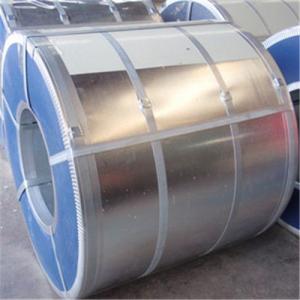

Cold Rolled Steel Coils for roof construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPCC cold rolled steel plate/cold rolled sheet building and construction | ||

Material | Standard | JIS G3141.GB/T 708-2006,EN10130,ASTM A366, GB11253-89, JIS G3141,DIN1623,EN10130 |

Grade | SPCC,DC01,DCO2,SPCG,Q195,Q235,SPCE,SPCD,ect | |

Size details | Thickness | 0.1-4.5mm |

Width | 750-1500mm | |

Coil ID | 508/610mm | |

Weight coil | 5-12tons for each coil | |

Surface finished | General, bright,oiled or non-oiled | |

Technique | Cold rolled | |

Certificates | ISO9001:2000,CE, BV, | |

Packing | craft paper +steel pallet packing/steel box+steel pallet | |

Productivity | 1000T/M | |

Application | 1.common structural parts and parts for drawing in engineering machines 2.transportation machine construction machines, lifting machine 3.agricultural machines, light and civil industrial, household appliance industries. 4. chemical equipments, drive casing pipe and light industrial civil | |

- Q: How are steel coils used in the packaging industry?

- Steel coils are used in the packaging industry to create sturdy and durable packaging materials, such as metal drums, cans, and containers. The coils are unwound and shaped into the desired form, providing a strong and protective barrier for various products during storage and transportation.

- Q: Is Carbon Steel strong for swords?

- Depends on the sword design. Some swords are high carbon, some a low carbon, some are made from a billet of alternating high and low carbon ('Damascus' steels). It all depends on what characteristics you want for your sword. Softer steels won't hold an edge as well but they offer great flexibility so your sword won't shatter when they make impact with armor or shields. Harder steels hold better edges but they're prone to binding in wooden shields and then being broken as soon as a bending force is applied along the weak axis of the blade. Japanese Katanas have both hard and soft steels to allow the blade to bend yet still hold strong edges. If you're making the sword from raw materials on your own, look up some different recipes for crucible steel. It's probably the most fun and involved process.

- Q: What are the different types of steel coil edge finishes?

- There are several types of steel coil edge finishes, including mill edge, slit edge, round edge, and deburred edge.

- Q: How are steel coils used in the production of heating systems?

- Steel coils are used in the production of heating systems in various ways. One of the main uses of steel coils in heating systems is in the construction of heat exchangers. Heat exchangers play a crucial role in transferring heat from one medium to another within the heating system. The steel coils are typically formed into a series of tubes or fins, which provide a large surface area for efficient heat transfer. In a typical heating system, hot gases or liquids pass through these steel coils, while another medium, such as air or water, flows over or through the coils. This allows for the transfer of heat energy from the hot medium to the cooler medium, thereby effectively heating the air or water for distribution throughout the heating system. Another use of steel coils in heating systems is for the production of radiant heating panels or floor heating systems. In these applications, the steel coils are typically embedded within a panel or underneath the flooring. When electricity or hot water is passed through the coils, they heat up, radiating heat to the surrounding environment. This type of heating system is particularly efficient and provides a comfortable and even distribution of heat. Furthermore, steel coils are also used in the manufacturing of heating system components such as boilers, furnaces, and heat pumps. These components often require the use of steel coils for their heat transfer capabilities and durability. The coils are integrated into the design of these heating system units to ensure efficient and reliable heat generation and distribution. Overall, steel coils play a crucial role in the production of heating systems by enabling efficient heat transfer, providing durability, and facilitating the generation and distribution of heat.

- Q: i have a computer chair where the metal part that attachs the top part to the bottom with wheels has cracked around half of the assembly. my dad said it might be able to be repaired with jb weld. can jb weld fix it? how strong is jb weld? is it as strong as steel?

- the stuff is pretty strong... i have a friend who blew a hole in his crankcase of his 07 cr450f and used jb weld on it... added oil and rode on it.. the stuff is crazy strong just give it a day to dry

- Q: What are the dimensions of steel coils used in the building materials industry?

- The dimensions of steel coils used in the building materials industry can vary depending on the specific application and requirements. However, common dimensions for steel coils used in this industry typically range from 0.5mm to 3mm in thickness and 600mm to 1500mm in width. The length of the coil can vary depending on the manufacturer and customer specifications. It is also important to note that the weight of the coil can vary, with typical weights ranging from a few hundred kilograms to several tonnes, depending on the size and thickness of the coil. Ultimately, the dimensions of steel coils in the building materials industry are determined by the specific needs and specifications of the construction projects they are intended for.

- Q: What are the different methods of surface inspection for steel coils?

- Some of the different methods of surface inspection for steel coils include visual inspection, magnetic particle inspection, dye penetrant inspection, eddy current inspection, and ultrasonic inspection.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils are used in the production of electronic devices for various purposes, such as creating magnetic fields, providing structural support, and acting as conductors in transformers and inductors. These coils are typically wound around a core material, such as ferrite or laminated iron, to enhance their magnetic properties and improve their performance in electronic circuits.

- Q: I moved into a house which has a steel front door.When I touch the door it feels very cold to the touch in the winter.There is a storm door also and the weather stripping looks good.Cold air from the door is entering the lower level.The house is about 20 yrs old.

- Not all steel doors are. Its about 20* where i am and my steel door feel somewhat cold, but not very cold. Yours could not be? If you take the lock off the door and look inside the hole where the lock was you should see insulation inside your door.

- Q: What industries use steel coils?

- Several industries use steel coils, including automotive, construction, manufacturing, and transportation. Steel coils are commonly used in the production of various metal parts, components, and structures due to their durability, strength, and versatility. They are utilized in manufacturing automobiles, appliances, pipes, roofing materials, and even in the construction of bridges and buildings. Additionally, steel coils are essential in the transportation industry for the fabrication of railcars, ships, and other heavy-duty vehicles.

Send your message to us

Cold Rolled Steel Coils for roof construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords