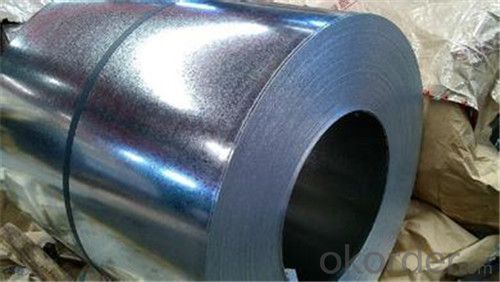

cold rolled steel coil for roof construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name | steel coil |

Grade | SPCC,SPCD ,SPCE, Q235 |

BASE PLATE | Cold rolled steel sheet, hot dipped zinc coated steel sheet hot dipped A-Z coated steel sheet |

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.2mm—2.0mm |

WIDTH | 600-1250MM |

SUREFACE QUALITY | Ⅰ - advanced finishing surface, Ⅱ - more advanced finishing surface, Ⅲ - ordinary finishing surface |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

Heat treatment condition | A - annealing, S - annealing + flat, 8 - (1/8) of the hard hard, 2, 4 - (1/4) - hard, 1 (1/2) - hard. |

Advantages:

a. Our company produce various specification and models and national standards

of steel coil

b. Using high-quality material and advanced production technology and equipment

for processing

c. Applicable to a humid climate and the harsh corrosive environment

d. Products has been all over the country more than 20 provinces, municipalities and autonomous regions, and have been exported to Europe, North American, the Middle

East, the South East Asia, Africa, Asia,European

Main characteristics :

1.strong corrosion resistance

2.surface quality

3.conducive to deep processing

4.economy and practicality

Packaging & Delivery:

| Packaging Detail: | 1,Each bare coil to be securely tied with two bands through the eye of coil (or not) and one circumferential. 2,the contact points of these bands on the coil edge to be protect with edge protectors. 3,Coil then to be properly wrapped with water proof /resistant paper, it then to be properly and completely metal wrapped. 4,Wooden and iron pallet can be used or as your requirements. |

| Delivery Detail: | 7-30 days |

Production Process :

Un-coiler------stitching machine-----barrels-----tension machine-----uncoil-----alkali washing and degreasing-----cleaning----drying----passivation-----drying

----cooling----coil----packing and warehousing

- Q: How are steel coils used in the production of building systems?

- Steel coils are used in the production of building systems as they provide a cost-effective and versatile material for various construction applications. These coils are often processed and shaped into different components, such as beams, columns, and roofing materials, to meet the structural requirements of buildings. The strength and durability of steel make it an ideal choice for constructing high-rise buildings, industrial facilities, and other structures that require stability and longevity.

- Q: What is the role of steel coils in the manufacturing of appliances?

- Steel coils play a crucial role in the manufacturing of appliances as they serve as the primary material for constructing the appliance's body and various components. The coils are processed, shaped, and transformed into different parts, such as the outer casing, inner structures, and internal components, providing strength, durability, and stability to the appliances. Additionally, the steel coils can be easily customized to meet specific design requirements, ensuring the appliances are efficient, reliable, and capable of withstanding the demands of daily use.

- Q: What are the different types of steel surface finishes for coils?

- There are several types of steel surface finishes for coils, including mill finish, galvanized finish, coated finish, and polished finish. Mill finish refers to the natural, untreated surface of the steel, which may have slight imperfections. Galvanized finish involves coating the steel with a layer of zinc to enhance corrosion resistance. Coated finishes can include various types of coatings such as paint, epoxy, or polymer to provide protection and aesthetic appeal. Lastly, a polished finish involves buffing or grinding the steel surface to create a smooth, reflective appearance.

- Q: how much pressure can steel withstand? and how much pressure can concrete withstand? per m3 or cm3? thanks

- A common allowable stress for steel is 24,000 psi for A36 steel. Note that allowable stress is a working stress that is less than ultimate stress the stress at which the material will rupture. This allowable stress keeps the steel within the elastic range. Concrete allowable stress is typically around 3000 psi. Concrete, though, being a mixed material has variable values for allowable stress. Reinforced concrete design theory suggests that concrete should not be considered to be able to carry much, if any, tensile force. This explains why you will see steel rebar or reinforcing bars cast in to the concrete. The steel is there to carry any tensile forces, while the concrete is there to carry compression forces. This is a VERY basic explanation. There are entire books on both of these subjects...

- Q: What are the common applications of steel coils?

- Steel coils have a wide range of applications across various industries, including automotive, construction, manufacturing, and appliance sectors. They are commonly used in the production of automobiles, machinery, and infrastructure components like bridges and buildings. Additionally, steel coils are utilized in the manufacturing of household appliances, such as refrigerators and washing machines. Their versatility, strength, and durability make steel coils a crucial material for many industrial applications.

- Q: What are the common coil diameter and weight combinations available for steel coils?

- The available combinations of coil diameter and weight for steel coils vary depending on specific requirements and industry standards. However, the market offers commonly used combinations that are widely accessible. Coil diameter commonly ranges from 24 inches (610 mm) to 72 inches (1829 mm). These sizes are often utilized in industries such as automotive, construction, and manufacturing. Coil weight varies significantly based on the steel type and thickness. In the case of hot-rolled coils, the weight typically falls between 5 to 30 metric tons. For cold-rolled coils, the weight usually ranges from 2 to 20 metric tons. Heavier coils are commonly applied in heavy-duty situations, while lighter coils are preferred for delicate or precise applications. It's important to remember that these are general guidelines, and the actual combinations of coil diameter and weight can be customized to meet a customer's specific needs. Different manufacturers and suppliers offer a wide range of options to accommodate various industry requirements. Therefore, it is advisable to consult with the specific supplier to determine the available coil diameter and weight combinations that best suit your application.

- Q: Can steel coils be used in corrosive environments?

- Yes, steel coils can be used in corrosive environments, but their performance will depend on the type of steel and the severity of the corrosive environment. Stainless steel coils, for example, are highly resistant to corrosion and can be used in a wide range of corrosive environments, including those with high levels of moisture, chemicals, or salt. However, other types of steel coils may require additional protective measures, such as coatings or galvanization, to enhance their resistance to corrosion. It is important to consider the specific corrosive factors present in the environment and choose the appropriate type of steel and protective measures to ensure the longevity and durability of the steel coils.

- Q: How are steel coils used in the production of electronic devices?

- Steel coils find extensive application in the production of electronic devices, serving various purposes. One prominent utilization lies in the manufacturing of transformers and inductors, which constitute essential components in numerous electronic devices. These components comprise a coil of wire wound around a core, with steel coils often serving as the core material due to their magnetic properties. The magnetic properties of steel contribute to amplifying the magnetic fields generated by the coils, facilitating effective energy transfer and voltage regulation. Steel's magnetic attributes, such as high permeability and low hysteresis loss, make it an ideal material for such applications. Furthermore, steel coils are also integral to the production of printed circuit boards (PCBs). PCBs, acting as the backbone of most electronic devices, consist of a flat, non-conductive board like fiberglass, adorned with a thin layer of copper traces etched onto it. These copper traces establish the electrical connections between different components on the board. Steel coils play a role in the PCB fabrication process, specifically in the creation of stencils. These stencils are employed to apply solder paste onto the board before component placement. Laser-cut steel coils give rise to accurate and consistent stencil patterns, ensuring precise solder paste application. To summarize, steel coils fulfill a crucial function in the production of electronic devices. They are employed in the manufacturing of transformers and inductors, enhancing energy transfer and voltage regulation through their magnetic properties. Additionally, steel coils contribute to the fabrication of PCBs by creating stencils for solder paste application. Overall, the use of steel coils guarantees the efficient and dependable operation of electronic devices.

- Q: What are the main factors that affect the surface quality of steel coils?

- The main factors that affect the surface quality of steel coils include the cleanliness of the steel surface, the presence of any defects or imperfections, the level of surface roughness, the coating or finishing applied to the surface, and the handling and storage conditions of the coils.

- Q: Can steel coils be stacked on top of each other?

- Yes, steel coils can be stacked on top of each other.

Send your message to us

cold rolled steel coil for roof construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 36 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords