Al-Zinc coated steel coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

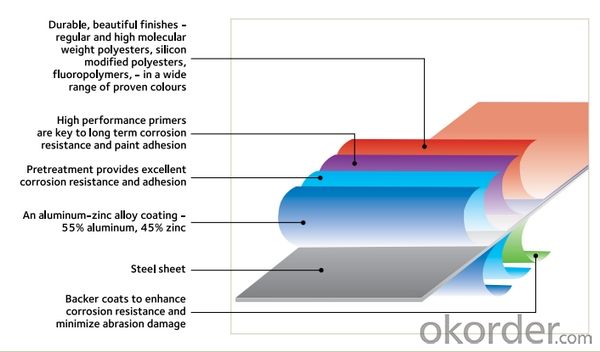

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: what do you think about it? Is it a good steel for the money? the knife that i have with that steel is the kershaw chill. good knife for the price

- 8Cr13MoV is a decent blade steel...not a great steel, but about as good as you will generally find without paying much higher prices. It's used by a number of well known knife makers... It's basically equivalent to AUS-8 and will work and hold an edge reasonably well for most basic cutting chores. *************************************** From Wikipedia, the free encyclopedia: 8Cr13MoV, a Chinese stainless steel tempered at the Rc56 to Rc58 range and used in the Tenacious, Persistence, Ambitious, Resilience, Grasshopper, Kiwi3 and Byrd lines of knives. Often compared to AUS-8, but with slightly more Carbon.

- Q: How are steel coils coated?

- Steel coils are typically coated through a process known as coil coating, which involves applying a protective layer to the surface of the steel. This is done by passing the coil through a series of rollers that apply the coating material evenly across the entire surface. The coating can be applied using various methods such as roll coating, spray coating, or electrostatic coating, depending on the desired finish and properties. The coated steel coils are then cured or baked to ensure the coating adheres properly and provides the desired level of protection and durability.

- Q: I am currently writing a manuscript, and would like to know whether guns made out of steel, burn or melt when exposed to flames. Thanks.

- Any steel will burn in the Presence of pure oxygen and high heat, that's how a cutting torch works.

- Q: How are steel coils inspected for paint adhesion using adhesion testers?

- Steel coils are inspected for paint adhesion using adhesion testers by applying a controlled amount of force to a specially prepared test area on the coil's surface. The adhesion tester measures the amount of force required to remove the paint coating from the surface, providing a quantitative assessment of the paint adhesion. This process helps ensure the quality and durability of the paint coating on the steel coils.

- Q: What is the average width tolerance for steel coils?

- The average width tolerance for steel coils can vary depending on the specific requirements and standards set by the industry. However, a common range for width tolerance in steel coils is typically around ±0.005 to ±0.030 inches.

- Q: What are the key players in the steel coil manufacturing industry?

- The key players in the steel coil manufacturing industry are typically large multinational companies that have significant market share and influence. Some of the prominent players in the industry include: 1. ArcelorMittal: As the world's largest steel producer, ArcelorMittal is a major player in the steel coil manufacturing industry. They operate in more than 60 countries and have a diversified product portfolio. 2. Nippon Steel Corporation: Nippon Steel is a leading Japanese steelmaker and one of the largest steel coil manufacturers globally. They have a strong presence in automotive and construction sectors. 3. POSCO: Based in South Korea, POSCO is a major player in the steel industry, including steel coil manufacturing. They are known for their high-quality products and advanced technology. 4. Baosteel Group Corporation: Baosteel is the largest steelmaker in China and one of the largest globally. They have a wide range of steel products, including steel coils, and are known for their strong research and development capabilities. 5. Thyssenkrupp AG: Thyssenkrupp is a German multinational conglomerate with a significant presence in the steel coil manufacturing industry. They have a diverse product range and focus on innovation and sustainability. 6. United States Steel Corporation: As a leading American steel producer, United States Steel Corporation plays a crucial role in the steel coil manufacturing industry. They have a strong presence in the automotive, construction, and energy sectors. 7. JFE Holdings, Inc.: JFE Holdings is a Japanese steel conglomerate and one of the key players in the steel coil manufacturing industry. They have a wide range of steel products and are known for their quality and customer-oriented approach. These are just a few of the key players in the steel coil manufacturing industry, and there are many other companies that contribute to this sector. The industry is highly competitive, and these companies continuously strive to innovate, improve efficiency, and meet the ever-evolving demands of the market.

- Q: I like steel strings but don't want to get a new guitar. Is that my only option?

- It will permanently ruin the guitars neck. Acoustic guitars have an adjustable metal rod in them called a “Truss Rod” that allows the neck to withstand steel string tension. How about putting on high tension nylon strings ?

- Q: I have a tiara and it oxidized and I'm not sure what material it is. I know it it isn't metal so i was wondering if is steel? Also if it's steel, can I do something to clean it?

- Yes - Steel can oxidize, its most commonly called rust Steel is a metal. Depending on the level of oxidation, you might be able to polish it with very fine steel wool. If is is really bad, then you might need a chemical cleaner such as Naval Jelly, which can be found at the hardware store. But the Naval Jelly might discolor the metal, so then you might need to polish it afterward to return its finish.

- Q: What are the different types of steel coil finishing processes?

- There are several types of steel coil finishing processes, including hot rolling, cold rolling, galvanizing, and coating. Hot rolling involves passing the steel through high temperatures to shape and form it. Cold rolling is a similar process but is done at lower temperatures to improve the steel's surface finish and dimensional accuracy. Galvanizing is a process where a layer of zinc is applied to the steel to protect it from corrosion. Coating processes involve applying a layer of paint or other protective substances to enhance the steel's durability and aesthetics.

- Q: I'm trying to make a corset but I can't find any steel boning in my area. Any clue as to what materials I could buy to to make my own bones, or anything that would work similarly?I know there are places to buy it online, but the cost of shipping makes it barely seem worth it.

- Hi, buy the original bones. They are designed to corset's load. If you use any substitute material it could break and it could be cause of injuries. Use google for link to corset's bones suppliers. Look on:

Send your message to us

Al-Zinc coated steel coil for construction Roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords