Cold Rolled Stainless Steel 401 BA/2B 0.01mm-80mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Stainless Steel Coil:

Stainless steel coil is a production which not easy rust, acid resistance and corrosion resistance, Stainless steel coil is a new kind of Austenite stainless steel by used Mn, N replace Ni. so it is widely used in light industry, heavy industry, daily necessities and the decoration industry. Stainless steel coil has good corrosion resistance and hot / cold processing performance, instead of stainless steel products for used in the not high of corrosive environment, such as indoor, inland city outdoor etc.

2.Main Features of the Stainless steel coil:

1) High Quality: Using Latest automated control equipment to ensure the quality

2) Best Price: With most automated equipments to ensure our price is lower than the market

3) Fast Delivery: The delivery date within 20 das after get your order

4) Best Service: Our after-sell service team will help you to slove all the problems about the order

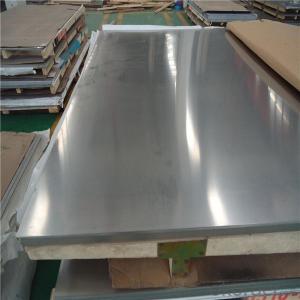

3. Stainless steel coil Images

4. Stainless steel coil Specification

Product name: 304 Stainless Steel Coil

Thickness: 0.2mm to 1.5mm

Technical: Cold Rolled

Width: 10mm to 1240mm

Type: 200 Series

Length: As customer's requested

Standard: JIS, SUS

Finish: BA, 2B, 8K, NO.3, NO.4, HL

MOQ: 100 MT

Ship Term: FOB Shenzhen port or CNF import port

Delivery Time: 15 to 20 day after the receive the deposit or LC

Packaging: By wooden pallet, wooden case or according to customer's request

5.FAQ

1) How about your company?

2) A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

3) How long can we receive the product after purchase?

4) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the benefits of using etched stainless steel sheets in signage?

- Using etched stainless steel sheets in signage comes with numerous advantages. Firstly, these sheets are incredibly durable and long-lasting due to stainless steel's resistance to corrosion, rust, and fading. This makes them perfect for outdoor signage that is exposed to harsh weather conditions. Secondly, etched stainless steel sheets provide a sleek and professional look. Through the process of etching, intricate designs, logos, and text can be permanently engraved onto the surface of the stainless steel. This results in a visually appealing finish that adds sophistication to any signage. Additionally, etched stainless steel sheets are highly customizable, allowing them to meet specific design requirements. This versatility makes them suitable for a wide range of signage applications such as architectural signage, company logos, directional signs, or wayfinding systems. They can be tailored to match any style or branding. Moreover, stainless steel is easy to clean and maintain. Simply wiping it down with a cloth or using mild soap and water will keep the signage in pristine condition for an extended period. This low maintenance requirement is particularly advantageous for outdoor signage that may require regular cleaning. Lastly, etched stainless steel sheets offer excellent visibility. By filling the engraved designs on the stainless steel surface with paint or other materials, the signage becomes highly visible even from a distance or in low light conditions. This enhanced visibility ensures that the intended message or information is effectively communicated to the target audience. In conclusion, the use of etched stainless steel sheets in signage provides durability, a professional appearance, customization options, easy maintenance, and excellent visibility. These advantages have made etched stainless steel sheets a popular choice for signage applications across various industries.

- Q: How do you prevent fingerprints or smudges on stainless steel sheets?

- To prevent fingerprints or smudges on stainless steel sheets, it is important to regularly clean and maintain the surface. Use a soft, lint-free cloth and mild detergent to gently wipe the stainless steel, following the grain. Avoid using abrasive cleaners or scrubbing pads as they can cause scratches. Additionally, applying a stainless steel cleaner or polish can create a protective barrier and enhance the resistance to fingerprints.

- Q: What's the drill for stainless steel?

- Stainless steel is characterized by high toughness, easy to stick the knife, so requires higher hardness of the drill bit, surface finish is better, the drill tip angle than the ordinary drill (130--135 degrees). At the same time, cooling should be sufficient

- Q: What are stainless steel sheets?

- Stainless steel sheets are flat metal plates made from an alloy of iron, chromium, and other elements that prevent corrosion and rusting. They are commonly used in various industries such as construction, automotive, and manufacturing, due to their durability, strength, and resistance to staining and oxidation.

- Q: Are stainless steel sheets suitable for outdoor furniture?

- Yes, stainless steel sheets are highly suitable for outdoor furniture. Stainless steel is known for its exceptional durability, resistance to corrosion, and ability to withstand various weather conditions. It also offers a sleek and modern appearance, making it a popular choice for outdoor furniture that can withstand the elements and maintain its aesthetic appeal.

- Q: How do you prevent staining on stainless steel sheets?

- To prevent staining on stainless steel sheets, it is important to regularly clean and maintain them. This can be done by using non-abrasive cleaners specifically designed for stainless steel, avoiding harsh chemicals and abrasive materials that can scratch the surface. Additionally, wiping away spills or moisture promptly and drying the sheets thoroughly after cleaning can help prevent staining. Using protective coatings or sealants specifically made for stainless steel can also offer an extra layer of protection against staining.

- Q: What is the difference between 304 and 316 stainless steel sheets?

- The main difference between 304 and 316 stainless steel sheets is their composition and corrosion resistance. 304 stainless steel contains 18% chromium and 8% nickel, while 316 stainless steel contains 16% chromium, 10% nickel, and 2% molybdenum. This additional molybdenum in 316 stainless steel improves its corrosion resistance, making it more suitable for use in marine environments or applications exposed to harsh chemicals. Therefore, 316 stainless steel sheets are generally considered more corrosion resistant than 304 stainless steel sheets.

- Q: What's the difference between 201 and 204 stainless steel plates? Thank you

- Different components: the main difference in nickel containing impurities, 201 such products performance 04 corrosion resistance, stamping performance far better than the 01, the 04 is generally used in complex environment, need strong resistance to corrosion for 01 place, environmental requirements are not very high, or the stainless steel demand is not high place

- Q: Can stainless steel sheets be used for water filtration systems?

- Certainly, water filtration systems can make use of stainless steel sheets. Due to their outstanding corrosion resistance and durability, stainless steel is widely employed in water filtration. It possesses the ability to withstand high pressure, temperature fluctuations, and exposure to various chemicals, rendering it suitable for prolonged use in water filtration applications. Moreover, the smooth surface of stainless steel sheets facilitates effortless cleaning and prevents the accumulation of bacteria and other impurities. Furthermore, stainless steel is a non-reactive material, guaranteeing the absence of any harmful substances in the filtered water and ensuring its safety for consumption. In conclusion, stainless steel sheets are a dependable and efficient choice for water filtration systems.

- Q: Can stainless steel sheets be used for medical instrument trays?

- Indeed, medical instrument trays can make use of stainless steel sheets. The medical industry frequently utilizes stainless steel because of its remarkable resistance to corrosion, durability, and ease of cleaning. Medical instrument trays serve the purpose of storing and arranging diverse medical instruments during procedures. Stainless steel sheets are well-suited for this task due to their non-reactive nature and ability to withstand frequent sterilization processes, such as autoclaving. Furthermore, stainless steel possesses a sleek surface that can withstand scratches and dents, ensuring that the trays remain hygienic and easy to clean. All in all, stainless steel sheets prove to be a dependable and appropriate material option for medical instrument trays.

Send your message to us

Cold Rolled Stainless Steel 401 BA/2B 0.01mm-80mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords