201/304/316/430 Cold Rolled Stainless Steel Sheet Manufacture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Stainless Steel Sheet

304 stainless steel is the most widely used in the 300 series stainless steel. Its anti-corrosion property is stronger than the 200-series stainless steel, but the anti-acid property is worse than 316. 304 stainless steel have a good resistance in high temperature and the excellent corrosion resistance. 304 stainless steel is more expensive than 201, cheaper than the 316.

1. Commodity: 304 Stainless Steel

2. Technique: Cold Rolled/hot rolled Stainless Steel

3. Grade: 304 Stainless Steel

4. Type: Stainless Steel Sheet/coil

5. Finish: 2B/Ba/8K/Emboss/Etch

6. Edge: mill edge /silted edge

7.Size:1219mm*2438mm,1219mm*3048mm,or as customized

Thickness | 0.3mm-3mm |

Width | 1000mm-2000mm |

Length | 1219mm ,3050mm,or as your requirement |

Material | 201/304/316 |

Standard | AISI,DIN,GB,JIS |

Finish | 2B,BA, Hot rolled, No.1-No.4 |

Stock | Width:1000mm,1219mm,1500mm,1800mm,2000mm Length:2000mm,2438mm,2500mm,6000mm,6096mm |

Usage | Tableware, cabinets, cooking utensils, wate heaters, architectural decoration, chemical industry and so on |

Minimum Quantity | 5 pieces |

Technique | Cold rolled and Hot rolled |

Productivity | 10000 tons / month |

Terms of Pa | T/T |

stainless steel coil/sheets surface treatment

Characteristics and application | |

2B | The surface brightness and flatness of 2B is better than 2D. Then through a special surface treatment to improve its mechanical properties, 2B could nearly satisfy comprehensive uses. |

NO.3 | Polished with abrasive belt of git#100#200,have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

NO.4 | Polished with abrasive belt of grit#150#180,have better brightness with discontinuous coarse stria, but thinner than NO.3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc, |

HL | Polished with abrasive belt of grit#150#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc |

8K | The product have excellent brightness and prefect reflexivity can be the nirror |

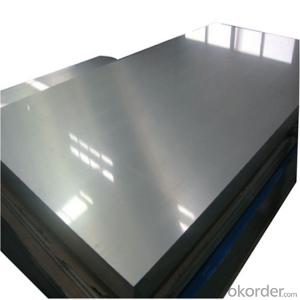

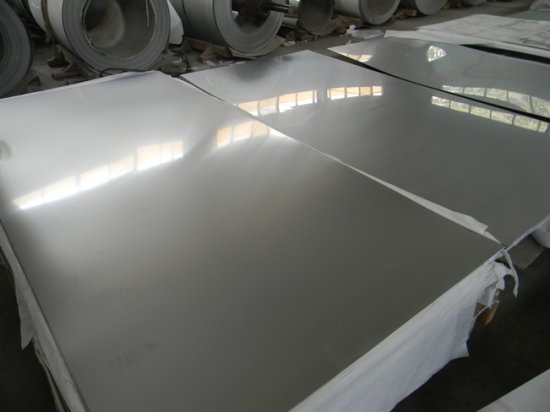

Products Pictures:

cold rolled stainless steel sheet(aisi201 sus304)

hot rolled stainless steel sheet,thick stainless steel sheet

- Q: Can stainless steel sheets be used for power generation equipment?

- Yes, stainless steel sheets can be used for power generation equipment. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for various applications in power generation, including turbine blades, heat exchangers, and electrical enclosures. Its high strength-to-weight ratio and resistance to extreme temperatures make it an ideal choice for reliable and long-lasting power generation equipment.

- Q: How do you prevent fingerprints and smudges on stainless steel sheets?

- To prevent fingerprints and smudges on stainless steel sheets, there are a few effective methods you can follow: 1. Clean with microfiber cloth: Use a soft microfiber cloth to wipe the stainless steel surface. Microfiber is gentle and won't leave any scratches or streaks. Avoid using rough materials like paper towels or abrasive sponges. 2. Use a stainless steel cleaner: Invest in a high-quality stainless steel cleaner specifically designed for removing fingerprints and smudges. Follow the instructions on the cleaner and apply it evenly on the surface using a cloth or a sponge. Wipe off any excess cleaner with a clean cloth. 3. Apply baby oil or mineral oil: Apply a small amount of baby oil or mineral oil on a cloth and rub it gently over the stainless steel surface. This will create a thin protective layer that helps prevent fingerprints and smudges from sticking to the metal. 4. Avoid touching the surface with bare hands: One of the main causes of fingerprints and smudges is direct contact with hands. Try to handle stainless steel sheets with clean, dry hands or wear gloves if necessary. This will help minimize the transfer of oils and residue onto the surface. 5. Regular cleaning routine: Establish a regular cleaning routine for your stainless steel sheets. Wipe them down with a microfiber cloth or stainless steel cleaner at least once a week, or more frequently in high-traffic areas. This will prevent the buildup of oils and grime, reducing the chances of fingerprints and smudges. By following these methods, you can effectively prevent fingerprints and smudges on stainless steel sheets, keeping them looking clean and shiny for an extended period of time.

- Q: Can stainless steel sheets be used for medical equipment?

- Yes, stainless steel sheets can be used for medical equipment. Stainless steel is widely used in the medical industry due to its excellent corrosion resistance, durability, and ease of cleaning. It is commonly used for surgical instruments, implants, medical devices, and equipment such as sterilization trays, hospital beds, and operating room tables. Stainless steel is non-reactive, which means it does not interact with body tissues or fluids, making it a safe and hygienic choice for medical applications. Additionally, stainless steel can withstand repeated sterilization processes without losing its properties, making it ideal for use in hospitals and healthcare facilities.

- Q: What is the difference between brushed and polished stainless steel sheets?

- Brushed and polished stainless steel sheets differ in terms of their appearance and texture. Brushed stainless steel sheets have a textured, matte finish that is achieved by brushing the stainless steel surface with an abrasive material. This creates a series of parallel lines or a pattern on the metal, giving it a distinctive look. The brushed finish helps to hide scratches and fingerprints, making it a popular choice for applications where durability is important. On the other hand, polished stainless steel sheets have a smooth, glossy finish that is achieved by polishing the surface with a fine abrasive compound. This process removes any imperfections or scratches on the metal, resulting in a mirror-like reflection. The polished finish is more reflective and visually appealing, making it commonly used in decorative applications where aesthetics are a priority. In summary, the main difference between brushed and polished stainless steel sheets lies in their appearance and texture. While brushed stainless steel sheets have a textured, matte finish that is more resistant to scratches and fingerprints, polished stainless steel sheets have a smooth, glossy finish that provides a mirror-like reflection. The choice between brushed and polished stainless steel sheets depends on the desired aesthetic and the specific application requirements.

- Q: Can stainless steel sheets be used for swimming pool installations?

- Yes, stainless steel sheets can be used for swimming pool installations. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for pool environments. It provides a sleek and modern aesthetic, and its resistance to rust and staining ensures longevity and ease of maintenance.

- Q: Are stainless steel sheets resistant to chemicals and acids?

- Stainless steel sheets possess resistance against chemicals and acids, thanks to the high percentage of chromium they contain. This results in the formation of a protective layer on the metal's surface, granting it exceptional resistance to corrosion and damage caused by chemicals and acids. Moreover, the inclusion of elements like nickel and molybdenum further enhances this corrosion-resistant quality. Industries like chemical processing, pharmaceuticals, food and beverage, and automotive widely employ stainless steel sheets due to their exposure to aggressive chemicals and acids. The reliability and durability of stainless steel in withstanding corrosion and chemical attack render it an ideal material for applications requiring such resistance.

- Q: What's the drill for stainless steel?

- The cutting fluid is made of concentrated emulsions. Commonly used stainless steel drills are: high cobalt bit (M35 bit, M42 bit), in which the M42 bit is the most cost-effective, and carbide drills are also available.

- Q: What are the different types of stainless steel sheet patterns available?

- There exists a variety of stainless steel sheet patterns, each possessing its own distinct design and characteristics. Some commonly encountered patterns include: 1. Smooth or plain: This pattern serves as the most elementary and widespread option, showcasing a sleek and uncomplicated surface without any discernible texture or design. 2. Satin or brushed: By subjecting the stainless steel sheet to the gentle abrasion of a fine grit abrasive, this pattern is achieved, resulting in a uniform and directional grain. It imparts a subtle and sophisticated appearance. 3. Quilted or diamond: With a raised diamond-shaped design on its surface, this pattern enhances traction and slip resistance. It finds frequent application in flooring, stairs, and industrial settings. 4. Linen: Resembling the texture of linen fabric, this pattern is achieved by etching a series of parallel lines onto the stainless steel sheet. It adds a distinctive visual appeal and is suitable for various uses, including interior design and architectural projects. 5. Perforated: Comprising a series of small holes or perforations punched into the stainless steel sheet, this pattern creates a visually captivating and functional design. It is commonly employed in situations requiring ventilation or filtration. 6. Tread or checker: Displaying a raised checkerboard design on the surface of the stainless steel sheet, this pattern offers a non-slip surface. It is often utilized in flooring, stairs, and transportation equipment. These examples merely scratch the surface of the diverse array of stainless steel sheet patterns available. Each pattern offers a unique combination of aesthetics and functionality, enabling versatile use across a wide range of applications.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, you can start by cleaning the surface with a mixture of warm water and mild detergent. Gently scrub the sheets using a soft sponge or cloth in the direction of the grain to avoid scratching. Rinse thoroughly and dry with a clean cloth. If the shine is still lacking, you can use a stainless steel cleaner or polish specifically designed for the material. Apply the cleaner following the product instructions, again following the grain, and wipe off any excess. This should help restore the shine and finish on your stainless steel sheets.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel is known for its excellent mechanical properties, corrosion resistance, and low thermal conductivity, which make it suitable for cryogenic environments. It can withstand the extreme cold temperatures without becoming brittle or losing its strength. Stainless steel sheets are commonly used in cryogenic applications such as storage tanks, piping systems, and cryogenic equipment. However, it is important to choose the appropriate grade of stainless steel that is specifically designed for cryogenic applications to ensure optimal performance and durability.

Send your message to us

201/304/316/430 Cold Rolled Stainless Steel Sheet Manufacture

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords