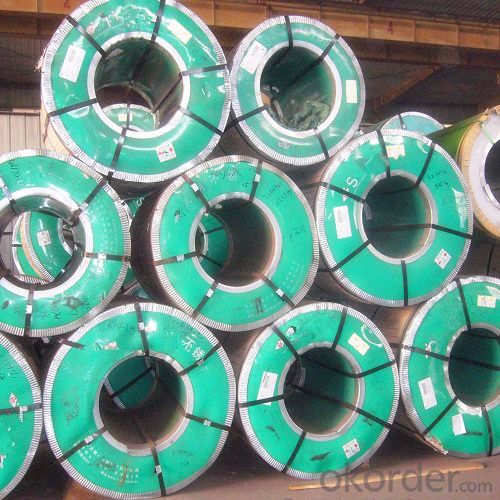

Stainless Steel Coil/Sheet 304 Cold Rolled BA/NO.1

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chemical composition: | |||||||

C | Si | Mn | Cr | Ni | S | P | |

≤0.07 | ≤1.0 | ≤2.0 | 18.0~20.0 | 8.0~11.0 | ≤0.03 | ≤0.035 | |

mechanical properties: | |||||||

Tensile strength σb (MPa) | Conditions yield strength 0.2 sigma (MPa) | Elongation δ5 (%) | Section shrinkage (%) | Hardness | |||

520 | 205 | 40 | 60 | ≤1 | |||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | 304 | Thickness: | 0.3-3.0mm |

Place of Origin: | China Mainland | Brand Name: | CNBM | Model Number: | 304 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | 2B, BA |

Application: | Medical instruments, building, chemical food industry agriculture | Width: | 500-2000mm | Length: | Coil |

finish: | 2B, BA | item: | 304 cold rolled stainless steel coil | density: | 7.93 |

Hot Rolled Stainless Steel Coil 304 Annealing and Pickling No.1 Finish

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.

Hot Rolled Stainless Steel Coil 304 Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 0.55m, 0.65m, 1.0m, 1.22m, 1.5m, 2m or requirement

Hot Rolled Stainless Steel Coil 304 Chemical Composition:

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Hot Rolled Stainless Steel Coil 304 Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

- Q: Can stainless steel strips be used in elevator components?

- Yes, stainless steel strips can be used in elevator components due to their durability, corrosion resistance, and strength.

- Q: What are the factors affecting the creep resistance of 111 stainless steel strips?

- The factors affecting the creep resistance of 111 stainless steel strips include the alloy composition, grain size, temperature, and applied stress. The presence of elements like chromium, nickel, and molybdenum enhances creep resistance. A fine grain structure enhances resistance, while higher temperatures and applied stresses can reduce the creep resistance of the stainless steel strips.

- Q: What are the different types of surface finishes for stainless steel strips?

- There are several different types of surface finishes that are commonly used for stainless steel strips. These finishes are applied to the surface of the stainless steel in order to improve its appearance, increase its corrosion resistance, and enhance its durability. 1. Mill Finish: This is the most basic type of surface finish, which is achieved by leaving the stainless steel strip in its original, as-produced state. It has a dull, non-reflective appearance and may have visible imperfections or marks from the manufacturing process. 2. No. 1 Finish: Also known as hot-rolled annealed and pickled (HRAP), this finish is achieved by annealing the stainless steel strip and then pickling it in acid. It has a smooth, reflective surface with a slightly matte appearance. No. 1 finish is commonly used in industrial applications where surface appearance is not a primary concern. 3. No. 2B Finish: This finish is achieved by cold-rolling the stainless steel strip and then annealing and pickling it. It has a smooth, reflective surface with a bright, semi-reflective appearance. No. 2B finish is commonly used in applications that require a good balance between appearance and corrosion resistance, such as kitchen appliances and architectural elements. 4. No. 4 Finish: Also known as brushed or satin finish, this finish is achieved by mechanically polishing the stainless steel strip with abrasive materials. It has a smooth, matte appearance with fine parallel lines, giving it a brushed texture. No. 4 finish is commonly used in decorative applications, such as furniture, elevator panels, and decorative trims. 5. No. 8 Finish: Also known as mirror finish, this finish is achieved by polishing the stainless steel strip to a highly reflective surface. It has a mirror-like appearance with excellent reflectivity. No. 8 finish is commonly used in architectural and decorative applications that require a high-end, polished look, such as signage, jewelry, and automotive trims. In addition to these main surface finishes, there are also other specialized finishes available for specific applications, such as embossed finishes, patterned finishes, and colored finishes. These finishes further enhance the aesthetic appeal and functionality of stainless steel strips in various industries.

- Q: Can 111 stainless steel strips be stamped or embossed for decorative purposes?

- Yes, 111 stainless steel strips can be stamped or embossed for decorative purposes.

- Q: Are stainless steel strips suitable for elevator doors?

- Yes, stainless steel strips are suitable for elevator doors. Stainless steel is a durable and corrosion-resistant material that is widely used in various applications, including elevator doors. Its strength and resistance to wear make it an ideal choice for elevator doors, as they are subject to heavy usage and constant contact with passengers. Additionally, stainless steel has a sleek and modern appearance, which can enhance the overall aesthetic of the elevator and provide a professional and sophisticated look. Overall, stainless steel strips offer the necessary durability, functionality, and visual appeal required for elevator doors.

- Q: What is the average lifespan of stainless steel strips?

- The lifespan of stainless steel strips can differ based on a variety of factors, including the grade and quality of the steel, the environment in which they are used, and the level of maintenance and care they receive. Generally, stainless steel is recognized for its durability and resistance to corrosion, which can contribute to a longer lifespan compared to other materials. In well-maintained and non-corrosive environments, stainless steel strips can endure for several decades. However, if the strips come into contact with harsh chemicals, high temperatures, or abrasive conditions, their lifespan may be reduced. Regular cleaning and maintenance, such as removing accumulated dirt or debris, can also aid in extending the lifespan of stainless steel strips. It is important to understand that the average lifespan is merely an estimation and can fluctuate depending on the specific application and usage circumstances. If you are considering using stainless steel strips for a particular project, it is advisable to seek guidance from a professional who can provide more precise information based on your specific requirements.

- Q: What is the weight of a typical stainless steel strip?

- The weight of a typical stainless steel strip can vary depending on its dimensions and thickness. However, as a general estimate, a stainless steel strip with a thickness of 0.5mm and a width of 25mm would weigh approximately 0.33 kilograms per meter. It is important to note that this weight can change significantly depending on the specific dimensions and composition of the stainless steel strip in question.

- Q: What are the common uses of stainless steel strips in the HVAC industry?

- Stainless steel strips are widely used in the HVAC (Heating, Ventilation, and Air Conditioning) industry due to their excellent properties and versatility. Some of the common uses of stainless steel strips in this industry include: 1. Ductwork: Stainless steel strips are commonly used for fabricating ducts in HVAC systems. The ducts made from stainless steel strips are durable, corrosion-resistant, and can withstand high temperatures and pressure. They provide a reliable and long-lasting solution for air distribution in residential, commercial, and industrial buildings. 2. Heat exchangers: Stainless steel strips are often utilized in the construction of heat exchangers, which are essential components in HVAC systems. Heat exchangers made from stainless steel strips provide efficient heat transfer, ensuring effective heating or cooling of air or water. The corrosion resistance of stainless steel makes it suitable for handling different fluids and prevents equipment failure due to rust or corrosion. 3. Ventilation systems: Stainless steel strips are commonly used in the manufacturing of ventilation systems, including air handling units, exhaust fans, and air filters. These systems require materials that can withstand harsh environments and maintain proper airflow. Stainless steel strips offer resistance to corrosion, heat, and chemical exposure, making them ideal for constructing durable and efficient ventilation systems. 4. Pipe and tubing: Stainless steel strips are frequently used for manufacturing pipes and tubing in HVAC applications. These components transport fluids such as refrigerants, coolants, and condensate. Stainless steel strips provide excellent resistance to corrosion, which is crucial in preventing leaks and ensuring the longevity of the HVAC system. 5. Furnace parts: Stainless steel strips are used in the fabrication of various furnace components, including burners, heat shields, and combustion chambers. These parts are exposed to high temperatures, flames, and corrosive gases. Stainless steel strips offer high-temperature resistance, oxidation resistance, and durability, ensuring the efficient and safe operation of furnaces in HVAC systems. Overall, stainless steel strips are valued in the HVAC industry for their durability, corrosion resistance, high-temperature resistance, and versatility. They play a crucial role in ensuring the efficiency, reliability, and longevity of HVAC systems in diverse applications.

- Q: Are stainless steel strips suitable for food processing?

- Yes, stainless steel strips are suitable for food processing. Stainless steel is highly resistant to corrosion, heat, and chemicals, making it a durable and hygienic material for food processing equipment. It is easy to clean, non-reactive, and does not impart any taste or odor to the food being processed.

- Q: Can stainless steel strips be used for electrical conductivity?

- No, stainless steel strips are not typically used for electrical conductivity. While stainless steel does have some electrical conductivity, it is relatively low when compared to other metals such as copper or aluminum. Therefore, stainless steel strips are not commonly used for applications that require high electrical conductivity.

Send your message to us

Stainless Steel Coil/Sheet 304 Cold Rolled BA/NO.1

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords