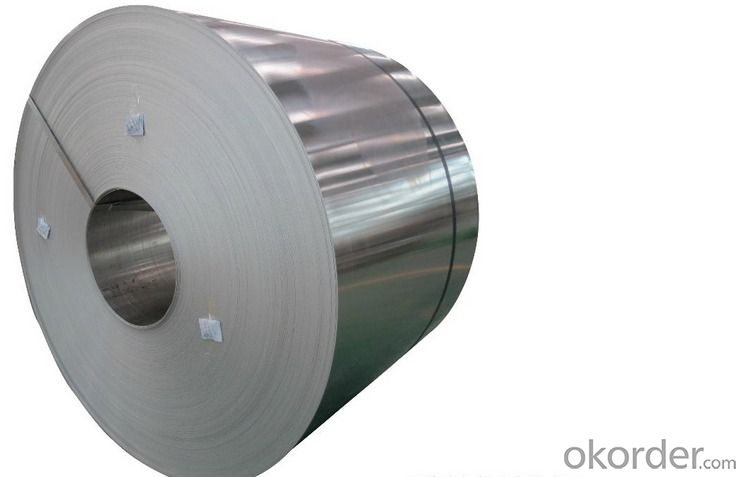

Aluminum Coil for Sale for Aluminum Composite Panel Base

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Alloy No. | Thickness | Width | Temper | |

A1050,A1060, A1070,A1100,A1235,A1245 | 0.2-3.0 | 20-2300 | O,H12,H22,H14,H24,H16,H26,H18 | |

4.0-12.0 | 1000-2300 | H111,H112 | ||

A3003,A3004,A3105 | 0.2-4.0 | 20-2300 | O,H12,H22,H14,H24,H16,H26,H18 | |

4.0-12.0 | 1000-2300 | H111,H112 | ||

A5052,A5083,A5754,A5005 | 0.2-4.0 | 20-2300 | O,H12,H22,H14,H24,H16,H26,H18 | |

4.0-12.0 | 1000-2300 | H111,H112 | ||

A6061,A6082,A6063 | 0.8-3.0 | 20-2300 | O | |

A8011,A1145,A1235 | 0.005-0.2 | 20-2300 | O,,H18,H24 | |

Inner Diameter: 76mm,152mm,200mm,300mm,505mm | ||||

Packing: Export wooden pallets, wooden case | ||||

Standards: ASTM-B209. EN573-1, GB/T3880.1-2006 | ||||

Further Specification:

Quality of material: totally free from defects like white rust, oil patches, roll marks, edge damage, camber, dents, holes, break lines, scratches and free from coil set | |

MOQ | 1 ton |

Payment term | TT,L/C |

Delivery Time | 15 days after 30% TT payment or receiving L/C copy |

Kind attention: Specifications can be customized as the customer’s requirements. | |

Application:

Mainly used in signs, billboards, building exterior decoration, bus body, high-rise buildings and factories

wall decoration, kitchen sink, lamp, fan leaves, with pieces of electronic, chemical equipment, sheet metal

processing parts, deep drawing or spinning hollowware, welding parts, heat exchangers, bell surface and disk,

plate, kitchenware, decorations, reflective devices, etc

FAQ of Aluminium coil for Aluminum composite panel base:

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can use decoiler machine, but after decoiling, the embossment of embossed aluminum sheet will become very shallow.

- Q: What are the common applications of aluminum coils?

- Due to their unique properties and versatility, aluminum coils are extensively used in various industries. They have numerous applications, some of which are highlighted below: 1. HVAC Systems: Aluminum coils play a crucial role in heat transfer in air conditioning and refrigeration systems. Their lightweight nature and excellent thermal conductivity make them an ideal choice for these purposes. 2. Transportation Industry: The automotive and aerospace industries commonly employ aluminum coils in the manufacturing of radiators, condensers, evaporators, and other heat exchange components. Aluminum's high strength-to-weight ratio helps in reducing the overall vehicle weight, resulting in improved fuel efficiency. 3. Construction Sector: The construction industry widely utilizes aluminum coils in the production of gutters, downspouts, roofing, and cladding materials. Aluminum's corrosion resistance and durability make it the preferred choice for outdoor applications that require long-lasting performance. 4. Electrical Industry: Aluminum coils are excellent for the production of cables, wires, transformers, and power distribution systems due to their exceptional electrical conductivity. 5. Packaging Industry: Aluminum coils are extensively used in producing various packaging materials, including cans, foils, and containers. Aluminum's ability to create a barrier against moisture, light, and oxygen makes it ideal for preserving the freshness and quality of food and beverages. 6. Marine Applications: The marine industry relies on aluminum coils for the manufacturing of boats, ships, and other offshore structures. Aluminum's resistance to corrosion in saltwater environments makes it suitable for these applications. 7. Industrial Equipment: Aluminum coils are utilized in various industrial equipment, such as heat exchangers, condensers, and evaporators. Their thermal conductivity and corrosion resistance properties enable efficient heat transfer. In conclusion, aluminum coils find widespread use in several industries, including HVAC, transportation, construction, electrical, packaging, marine, and industrial equipment. Their lightweight nature, excellent thermal conductivity, corrosion resistance, and durability make them highly desirable for a variety of applications.

- Q: How do you store aluminum coils to prevent damage?

- To prevent damage and store aluminum coils effectively, there are several important steps that can be taken. First and foremost, it is crucial to maintain a clean, dry storage area that is completely free from moisture and humidity. Moisture can gradually corrode the aluminum coils and cause significant damage over time. Secondly, it is advisable to store the coils in an upright position, preferably on pallets or racks, in order to avoid any bending or warping. By keeping them upright, the risk of coil deformation is minimized, ensuring that their shape remains intact for future use. Furthermore, it is recommended to shield the coils from dust, dirt, and other contaminants by covering them with a protective material such as plastic or tarp. This protective layer not only safeguards the coils from external particles but also isolates them from any potential chemical exposure that could accelerate corrosion. Additionally, it is of utmost importance to handle the coils with care during the storage process to prevent dents or scratches. Rough handling or accidental dropping can result in physical damage. Therefore, appropriate lifting equipment like forklifts or cranes should be used when moving or stacking the coils. Lastly, regular inspections should be carried out to check for any signs of damage or corrosion during storage. By conducting visual checks on a periodic basis, any issues can be identified early on, allowing for necessary interventions to prevent further damage. By adhering to these storage practices, damage to aluminum coils can be effectively prevented, ensuring their longevity and preserving their quality for future utilization.

- Q: What is the hardness of aluminum coils?

- The hardness of aluminum coils is subject to change due to several factors, including the particular alloy employed and the applied tempering process. Typically, in comparison to other metals, aluminum coils exhibit relatively low hardness. Aluminum is esteemed for its lightweight and pliable characteristics, rendering it effortlessly bendable and moldable. Nevertheless, by subjecting aluminum coils to diverse heat treatment methods like annealing or cold working, their hardness can be augmented to fulfill specific criteria. It should be emphasized that the hardness of aluminum coils can also fluctuate depending on the intended purpose and the desired degree of robustness and endurance.

- Q: What are the compositions of aluminum coil coating?

- Resin, pigment, auxiliary and solvent.

- Q: Is it possible to use aluminum coils for storage purposes?

- <p>Yes, aluminum coils can be used for storage, particularly for certain applications. They are often used in HVAC systems and electrical wiring due to their conductivity and flexibility. For general storage, aluminum coils may be suitable for winding and storing cables, wires, or similar materials. However, for storing items that require a specific environment or have weight concerns, it's important to consider the coil's strength and whether it can provide the necessary support and protection. Always ensure that the storage method complies with safety standards and the material's properties.</p>

- Q: I heard that clay pots and aluminum cans are great caves for my fish to breed in but will the can rust???

- Aluminum okorder /

- Q: Why does fillet appear when rolling aluminum coil?

- How thick and wide is it when there is such problem? Which is the rolling pass? And what is the type of the rolling mill? The simple 4 rollers or CVC and HC rolling mill with roller control. Does the filler appear in rolling or out of roller? Different thickness will lead to different analysis.

- Q: Why does it take less energy to get aluminum metal from used cans than to get it directly from the ore?

- in order to extract the raw aluminum, you have to heat everything and melt it first, then remove the stuff that precipitates out as it cools or forms via chemical reaction with catalysts you introduce. With aluminum cans, you don't have to raise the temperature much above the melting point of aluminum, since it's already the substance in the can with the highest melting point. With aluminum ore, there can be anything in the ore with pretty much any melting point. In particular, if the ore contains an alloy of aluminum and a metal with a higher melting point than aluminum, then rest assured, you will have to raise the temperature of the ore above the melting point of aluminum in order to melt that alloy, In any case, because the maximum required temperature of the smelter needed to melt used aluminum cans is necessarily lower than the maximum temperature required to work with the ore, less energy is required to get aluminum from used cans than from ore.

- Q: Are there any recycling programs for used aluminum coils?

- Yes, there are recycling programs available for used aluminum coils. Aluminum is highly recyclable and can be melted down and reused without losing its quality. Many recycling centers and scrap metal yards accept aluminum coils for recycling. Additionally, some HVAC (Heating, Ventilation, and Air Conditioning) companies have their own recycling programs for used aluminum coils, as they are commonly used in air conditioning systems. It is always recommended to check with your local recycling center or HVAC companies to inquire about specific recycling programs for used aluminum coils in your area.

Send your message to us

Aluminum Coil for Sale for Aluminum Composite Panel Base

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords