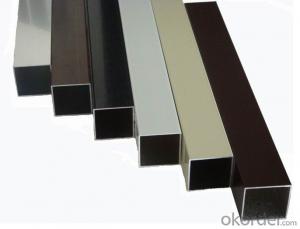

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

aluminium profile tube for construction

1.Square tube aluminium extrusion for door and window

2.aluminum window frame extrusion

3.aluminum extrusion profiles

| material | aluminium |

| color | silver, white, wood |

| sample | free offered |

| usage | door and window |

| MOQ | 5tons |

| surface treatment | powder coated / anodize |

| process | aluminium cutting |

| delivery time | 15-20days |

| shipping port | shanghai / ningbo |

| payment | T/T, Western Union, L/C |

| packing | shrink film |

if you want buy new products,we also can make moulding to produce for you,

we have own factory can produce plastic parts and die casting and metal products.

We are manufacturer for door and window handle, lock,hinge, roller, window operator, plastic parts,gasket, weather seal strip, screw, rivets, glass, pvc door, aluminium profile,door clsoer, crescent lock.

- Q: What are the water resistance properties of aluminum profiles?

- Aluminum profiles possess excellent water resistance properties. Aluminum itself is inherently resistant to corrosion, and when properly coated or anodized, it becomes even more resistant to water damage. The coating or anodization process creates a protective layer on the surface of the aluminum, which acts as a barrier against water penetration. Aluminum profiles are commonly used in various applications where they are exposed to water, such as windows, doors, and outdoor structures. Their water resistance properties ensure that they can withstand moisture, rain, and humidity without deteriorating or rusting. Furthermore, aluminum profiles have the advantage of being lightweight, which makes them ideal for use in water-related environments such as marine applications. Despite being lightweight, aluminum profiles offer high strength and durability, allowing them to withstand the harsh conditions associated with being in contact with water. In summary, aluminum profiles have excellent water resistance properties due to their natural resistance to corrosion and the protective coatings or anodization applied to their surfaces. This makes them a reliable choice for applications where exposure to water is expected, ensuring long-lasting performance and minimal maintenance requirements.

- Q: I am a mold professional, in school are mainly plastic mold and stamping die, but I am now in an aluminum extrusion die master apprentice. Draw pictures every day and walk around the workshop. But I have never met any related knowledge before, and I don't know where to start. I don't know what to do. Sometimes even want to give up, but not reconciled. I hope you can give me some advice. Thank you very much!!!

- With the stamping die almost the same, hard to learn ah!

- Q: Are aluminum profiles resistant to impact or vibration?

- Generally, aluminum profiles exhibit resistance to both impact and vibration. Aluminum is renowned for its high strength-to-weight ratio and exceptional durability. It possesses the ability to endure external forces and impacts without succumbing to deformation or fracture. Moreover, aluminum's innate characteristics grant it inherent resistance to vibration. Its capacity for high damping enables it to absorb and disperse vibrations, thereby diminishing their impact. Hence, aluminum profiles prove to be an optimal selection for applications necessitating resistance to impact or vibration, including the construction, automotive, aerospace, and marine sectors.

- Q: What are the noise reduction properties of aluminum profiles?

- Aluminum profiles have good noise reduction properties due to their ability to absorb and dampen sound vibrations. The high density and stiffness of aluminum help to minimize noise transmission, making it an effective material for reducing unwanted noise in various applications.

- Q: How to sell and sell industrial aluminium profiles?

- For the industrial aluminum profile enterprise, this is the most valuable customer resource, and also is the high-quality customer we usually call. Of course, the quality of customer mining, the most important thing is to discuss and communicate with customers. We must start from the position of customers, understand their requirements for products, know what they want to achieve the desired, can use their brains, for them to benefit by mutual discussion, analysis and reflection, so customers are thinking, anxious customers, so in fact, let customers choose our is the logical thing. It should be said that this is the most critical moment in the whole sale, so don't let yourself lose here.

- Q: What is the difference between aluminum alloy and 6063-T5 6060-T66?

- 6060-T66, higher strength, average mechanical performance is higher than T6 under 20-30Mpa condition [T66 is in T6 (solid solution strengthening + fully artificial aging) condition, strengthened by special process status - in European standard can be found] 6063-T5 is the most common aluminum alloy and delivery condition, and most of the architectural profiles are applied

- Q: What are aluminum profiles used for?

- Aluminum profiles are commonly used in construction, manufacturing, and industrial applications. They are used for framing structures, such as doors, windows, and curtain walls, providing strength and durability while maintaining a lightweight design. Additionally, aluminum profiles are used in the production of machinery, electrical enclosures, automotive parts, and various consumer products, due to their corrosion resistance, heat conductivity, and versatility in shaping.

- Q: How to identify and distinguish the inferior aluminum profile and the poor aluminum profile four?

- Third, the chemical composition is not qualified.Some manufacturers in order to retain customers, at the incorporation of a large number of miscellaneous scrap aluminum, aluminum can greatly reduce the cost, but will lead to industrial aluminum unqualified chemical compositions, seriously endanger the life of aluminum.Fourth, reduce the wall thickness of profiles.

- Q: How do aluminum profiles perform in earthquake-resistant structures?

- Aluminum profiles perform well in earthquake-resistant structures due to their lightweight yet strong properties. They have high strength-to-weight ratio, which helps in reducing the overall weight of the structure while providing sufficient strength to withstand seismic forces. Additionally, aluminum is highly ductile and can absorb a significant amount of energy during an earthquake, thereby reducing the risk of structural failure. Furthermore, aluminum profiles can be easily fabricated and assembled, offering flexibility in design and construction. Overall, aluminum profiles contribute to the resilience and performance of earthquake-resistant structures.

- Q: Are there any safety considerations when working with aluminum profiles?

- Working with aluminum profiles requires several safety considerations. Firstly, it is crucial to wear appropriate personal protective equipment (PPE) like gloves, safety glasses, and a dust mask. This is necessary because handling aluminum profiles can produce fine metal shavings and dust, which can be harmful if inhaled or come into contact with the skin or eyes. Moreover, ensuring proper ventilation in the work area is essential to reduce the accumulation of aluminum dust and fumes. This can be achieved by utilizing exhaust fans or opening windows and doors to allow fresh air circulation. When cutting or machining aluminum profiles, it is vital to use the correct tools and techniques to prevent accidents or injuries. This includes employing sharp blades or cutting tools specifically designed for aluminum to avoid kickback or other hazards. Additionally, careful handling of aluminum profiles is important as they may have sharp edges or corners that can cause cuts or injuries. It is crucial to use proper lifting techniques to prevent strain or back injuries when moving or installing aluminum profiles. Lastly, being aware of the potential fire hazards associated with aluminum dust is crucial. Aluminum dust is highly flammable and can ignite when exposed to an ignition source like a spark or open flame. Therefore, maintaining a clean work area and regularly removing any accumulated aluminum dust is necessary to minimize the risk of fire. By adhering to these safety considerations and taking necessary precautions, the risks associated with working with aluminum profiles can be minimized, ensuring a safe working environment.

Send your message to us

LED Aluminum Profiles for Furniture - Aluminium Rectangular Tubes

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords