Layfield Non Woven Geotextile - Coastal Beach Geotextile PP Woven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Coastal Beach Geotextile PP Woven Geotextile

Desciriptions:

PP Woven Geotextile Professioal Waterproof Geotextiles. A woven geotextiles is an economical solution for any civil engineering applications. It separates, stabilizes, and reinforces soils and allos allows for filtration. Woven geotextiles are manufactured by extruding polypropylene film and then slitting the film into individual yarns which are then woven to form the geotextiles.

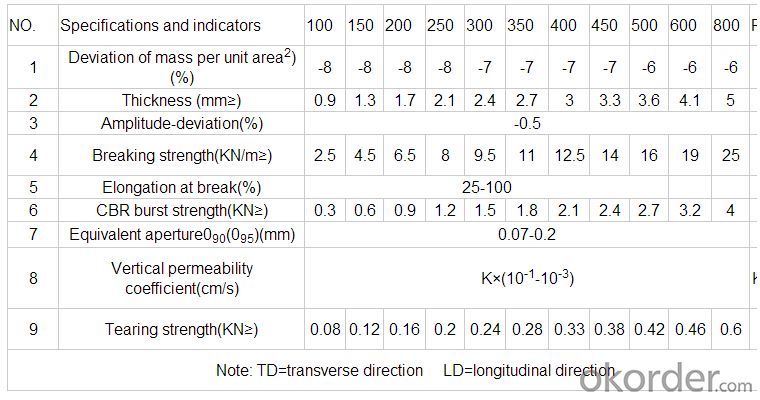

Specifications and Technical datas:

| Weight / Mass | 100gsm - 800gsm |

| width | Within 8 m |

| longth | 50-100m/roll (at request) |

| Material | PP / PET |

| Color | Black , white , grey |

| Certification | CE/ISO9001 |

| Manufacturing method | nonwoven / woven |

Characteristics:

Easy process and high output rates

Excellent distribution of carbon black

Consistent quality and low failure rate

Excellent resistance and good waterproof ability

Good welding

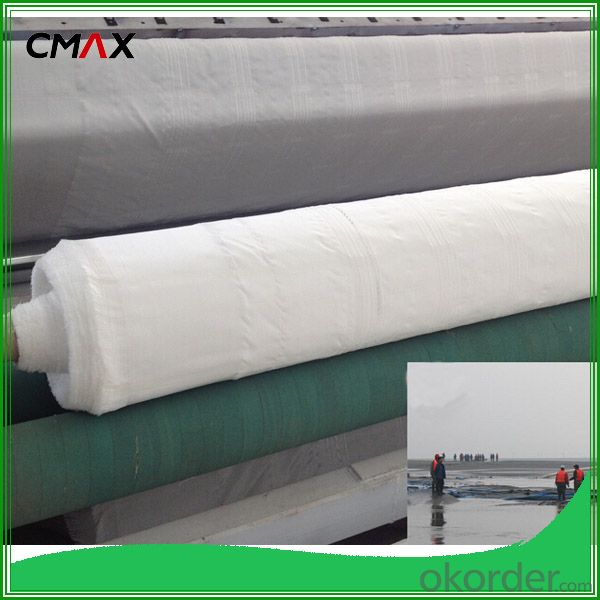

Details of our products:

Produce process:

Applications:

1) Filtration :

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

2) Separation :

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

3) Adding muscle :

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

4) Protection :

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Packing and shipping:

1. The outer package: black or white woven geotextile.or we can make the package as your requst.

2. Different tgram/ roll size for different qty in the same containers.

3. Roll size: 3.95m*200 for container

FAQ:

Q1: What is your minimum order quantity?

A:The minimum order quantity is 5000 ,but it is negotiable.

Q2:What is your payment terms?

A: T/T,Western Union,Paypal,L/C...

HDPE Geomembrane Price

Q3:What is your delivery time?

A:Production time usually costs 2-20 days.

Waiting to cooperate with you!

- Q: How is this set of water quotas? More

- Hello, I am specializing in the production of geotextiles and other geotextile materials,

- Q: Application standard of filament geotextile

- National standard for filament geotextiles GB / T-1998 Geosynthetics Filament anti - sticking acupuncture non - woven geotextiles, the latest standard GB / T - 2008.

- Q: Can geotextiles be used in drainage applications?

- Yes, geotextiles can be used in drainage applications. They are commonly used to improve the performance and longevity of drainage systems by preventing soil erosion, filtering out fine particles, and promoting water flow. Geotextiles can be placed in various drainage applications such as road construction, agricultural drainage, landfills, and erosion control to enhance their effectiveness and efficiency.

- Q: Geotextile manufacturers are what industry

- Geotextile manufacturing enterprises are textile and leather industry

- Q: How can we file in the Water Resources Department? I was doing hydraulic works with geotextiles, geogrids, gabion, gabbin.

- Water geotechnical engineering geotextile, geogrid, gabion, Geben network should belong to the geotextile material series, you can refer to the required record of the Department of Water Resources on the geotechnical industry for the record requirements. At present, the provinces and cities of the record requirements are not the same, you want to record in which provinces and cities will go to the provincial and municipal water conservancy department official website to see the specific requirements, the Internet will generally have publicity, you can call the consultation. The general information required for the record includes: business license, tax registration certificate, organization code certificate, national industrial production license, safety production license, ISO9000 / ISO certification, legal personality certificate, power of attorney, contract copy in recent years Three-year financial audit report, the company's basic household certification.

- Q: What are the advantages of using geotextiles in stormwater management systems?

- Geotextiles offer several advantages in stormwater management systems. Firstly, they provide effective sediment filtration, preventing soil erosion and the accumulation of pollutants in water bodies. Secondly, they enhance soil stability by reinforcing the ground and minimizing the risk of slope failures. Additionally, geotextiles promote water infiltration and drainage, reducing the chances of flooding and ponding. They are also cost-effective as they require less maintenance and have a longer lifespan compared to traditional erosion control methods. Overall, geotextiles play a crucial role in improving the overall performance and sustainability of stormwater management systems.

- Q: How do geotextiles improve the performance of pavements?

- Geotextiles improve the performance of pavements by providing reinforcement, stabilization, and filtration. They enhance the strength and load-bearing capacity of the pavement by distributing the applied load more evenly, reducing the likelihood of rutting and cracking. Geotextiles also prevent the intermixing of different layers of pavement materials, maintaining the integrity of the structure. Additionally, they promote drainage and filtration, preventing the accumulation of water and reducing the risk of damage caused by moisture.

- Q: Can China produce polypropylene filament geotextiles? Google knows

- Yes, I am professional production, wish smooth

- Q: Geotextile (two cloth a film) to detect the frequency requirements? On behalf of the number?

- Geotextile and geomembrane detection frequency is 100 volumes detection time.

- Q: Can geotextiles be used in green roof construction?

- Yes, geotextiles can be used in green roof construction. They are commonly used as a separation layer between the growing medium and the drainage layer, preventing the two layers from mixing while allowing water to drain freely. Geotextiles also help to retain moisture within the growing medium, providing an ideal environment for plant growth on green roofs.

Send your message to us

Layfield Non Woven Geotextile - Coastal Beach Geotextile PP Woven Geotextile

- Loading Port:

- Wenzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 20000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords