CMAX 600 Augered Pile Rig for Sale on Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX series spiral pile drill rig is a new type of simple drilling equipment with independent innovation, ideal for pile construction in solar panels, billboards, street lamp, fences, flagpoles, traffic signs, isolation net and simple houses, giving strong stratum adaptability and high efficiency.

◆ The rig is equipped with a large torque rotary head for strong power, which provides strong adaptability in stratum.

◆ The hydraulic system adjusts rotation and feed to the stratum conditions accurately, which ensures high drilling efficiency.

◆ The rig is equipped with a pile guide device to guarantee pile verticality and quality.

◆The rig can be equipped with various pile connecting devices according to the pile structure and size, which makes pile insertion flexible and efficient.

◆ In different stratum condition, the rig can be equipped with down-the-hole percussion, cutting, short spiral and other tools to achieve full stratum drilling.

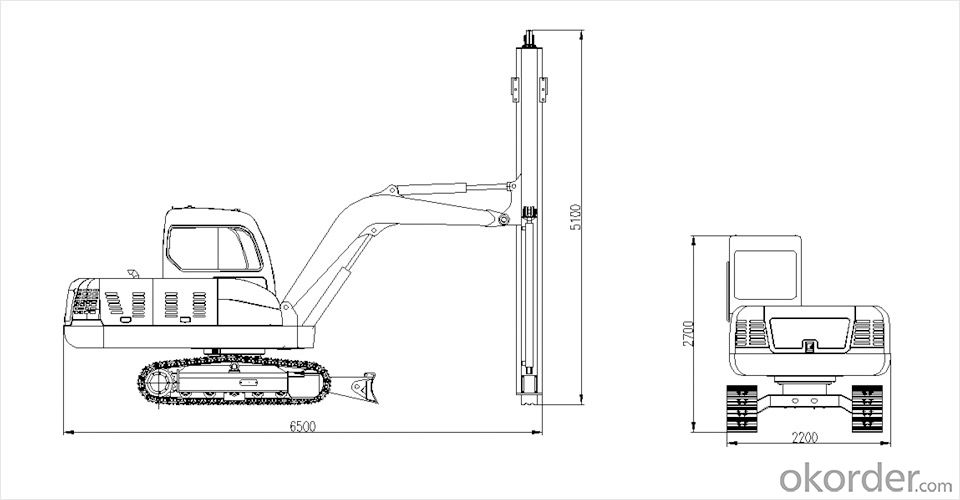

| MAIN DATA | UNIT | SWDL600 |

|---|---|---|

| OPERATION PARAMETER | ||

| Pile diameter | mm | 76~90 |

| Pile depth | m | 3 |

| CHASSIS | ||

| Track base | mm | 2240 |

| Gauge | mm | 1680 |

| Crawler width | mm | 400 |

| Ground clearance | mm | 340 |

| Blade length | mm | 2080 |

| ENGINE | ||

| Model | V3300-DI | |

| Displacement | L | 3.3 |

| Power/Speed | kW/rpm | 54.9/2600 |

| Fuel tank capacity | L | 140 |

| FEED | ||

| Length of drillrig | mm | 4800 |

| Feed length | mm | 3500 |

| Feed speed | m/min | 3 |

| Feed force | kN | 30 |

| TRAVELLING | ||

| Travel speed | km/h | 4.5/3.1 |

| Traction force, max | kN | 55 |

| Hill climbing ability | ° | 25 |

| ROTARY | ||

| Rotary speed, max | rpm | 40 |

| Rotary torque, max | Nm | 6000 |

| ENSION | ||

| Gross weight | t | 7.8 |

| Diamension(L×W×H) | m | 8.5×2.2×3.15 |

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

- Q: Invite friends together to buy a long spiral step of 30 meters of the pile driver, told me as long as the project profits are objective, you can package to 200W/, would like to ask the experts familiar with the bank bosses according to your local market if the annual package is how much money, how much is the monthly package, or by how many meters.. Thank you。。 Thank you

- The drilling system comprises a power head and the output shaft of the power drill head and screw drill is hollow, with long spiral hole, drill pipe through the center of the concrete [or] of the mud pumping concrete CFG pile construction, which can be a drilling machine once completed, can also be used to dry hole, grouting altering tool can also be taken deep mixing a variety of Engineering construction.

- Q: How many meters can a small pile driver reach?

- 1.2 meters in diameter, wylong machinery had sold a small machine

- Q: Excavators, pile drivers, how to operate? The master knows,

- Simple, first stop the car, push the right handle forward (big arm down), push the left hand lever (small arm out), handle the right (release bucket), do the above three actions at the same time until the bucket touches the ground. Then, the left handle back down and right arm handle down the left arm when receiving bucket, bucket is full. Then the big arm, left or right rotation and small rotating arm bucket on the line! Got it?! You can also question me!

- Q: How deep can a pile driver work?

- As the drill wylong machinery in rotary machine is capable of hitting at least 20 meters deep

- Q: Requirements of waveform guardrail column piling skills training program and training program.

- B, anti blocking blocks, wave beam, end installation(a) after installing the upright column, the bracket (block block) can be installed. The bracket (stop block) is fixed between the wave beam and the upright post through the connecting bolt. The bracket (block) shall be adjusted to make it in place before tightening the connecting bolts.(b) the wave beam is spliced with each other by a splicing bolt and is fixed by a connecting bolt bracket (an anti blocking block), and the direction of the overlap of the roadbed guardrail and the corrugated beam is the key of the installation, and the installation is carried out in strict accordance with the drawing. The direction of overlap shall be consistent with the driving direction. The wave beam should be adjusted continuously during the installation. Therefore, the connecting bolts and the splicing bolts should not be tightened too early so that the long holes in the corrugated beam can be adjusted in time during the installation process so as to form a smooth alignment and avoid local irregularities. When the alignment of the guardrail is considered satisfactory, the bolt can be screwed at last. The connecting bolt between the bracket (stop block) and the wave beam should not be screwed too tight, so that the temperature stress can be adjusted by using a long round hole.(c) the end beam is spliced with standard section guard bars through splicing bolts. The construction method of the end beam is basically the same as that of the wave beam.

- Q: What is the noise level of site construction (piling)?

- The construction is divided into several stages, and the noise limits are as follows:Earth stage, daytime noise limit is 75 dB, the night noise limit is 55 dBPiling stage, daytime noise limit is 85 dB, prohibit the construction of the night

- Q: How much power does piling work at a construction site?

- Depends on the type and power consumption of your pile driver

- Q: now to pull out, how can pull out? FiveThe machine can not be used, how to take out in a simple way! Now, how many tons of jacks do I need if I use a jack?

- Choose the proper crane and vibratory pile driver. Find out about the manufacturer.If Jack would estimate the pile weight of 14 tons, steel pipe in the soil weight of 50 tons, the friction pile is difficult to calculate, and the soil, curing time and pile, an estimated 600 tons to 2000 tons, to do a ring plate tooling, sheathed on the steel pipe, the gap should be small, on the tooling welding on the 1 meter long handle jack. Of course, you know, the hydraulic pad, the larger area, or the steel beam.

- Q: Several common pile foundations and pile driving techniques

- Bored pile foundation construction - long spiral drilling bored pile construction, the main processes are: site preparation, the laying of protective cylinders, preparation of mud, drilling, cleaning, reinforcement cage, into the hole and pouring underwater concrete. The key is drilling, the main methods are: rotating method, impact method and punching method. The rotary drilling can be divided into positive revolving drilling, reverse circulation rotary drilling, long spiral drilling machine and so on. Bored pile foundation construction - reverse and reverse rotating drilling, positive rotation drilling: mud from the mud pump at high pressure from the mud tank into the bore of the drill pipe, the drill hole through the mouth of the injection.

- Q: Clean the dirt and grease piling machine how much money

- The basic technical parameters of a pile driver are impact weight, impact kinetic energy and impact frequency. According to the motion of the pile hammer power source can be divided into hammer, hammer, diesel hammer, hydraulic hammer etc..

Send your message to us

CMAX 600 Augered Pile Rig for Sale on Okorder.com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords