Climbing-Bracket CB 210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

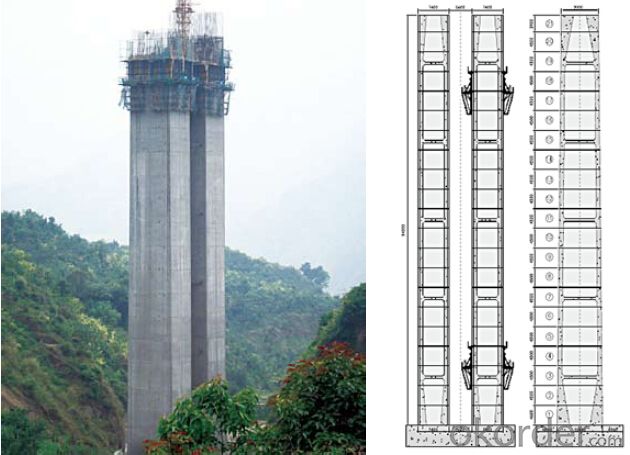

Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the

building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

Characteristics:

◆ High bearing capacity

The high loading capacity of the brackets allow very large scaffold units. This saves the number

anchor points required as well as reducing climbing times.

◆ Simple moving procedure by crane

Through the strong connection of formwork together with the climbing scaffold, both can be moved

as a single climbing unit by crane. Thus valuable time-savings can be achieved.

◆ Fast striking process without a crane

With the retrusive set, large formwork elements can also be retracted quickly and a minimum of

effort.

◆ Safe with work platform

The platforms have assembled firmly with bracket and will be climbing together, without scaffolding

but can work safely in spite of your high location.

- Q: What are the different types of form ties used in steel formwork?

- Steel formwork utilizes various types of form ties, each serving specific purposes and meeting distinct requirements. 1. Coil Ties: Flexibility and effortless installation and removal are provided by coil ties, which feature a coil rod with two to four coils. These ties are commonly utilized in lighter applications where lower pressure is anticipated. 2. Flat Ties: Constructed from steel, flat ties possess wide, flat plates on both ends. Their purpose is to connect opposing wall forms, ensuring stability and preventing bulging or spreading caused by concrete pressure. 3. She-Bolt Ties: She-bolt ties consist of a she-bolt attached to one end of a threaded rod. These ties secure wall forms together, and the threaded rod allows for easy formwork adjustment. 4. Snap Ties: Snap ties are a popular choice for swift and efficient formwork installation. They consist of a metal rod with a button-like head on one end and a wedge on the other. By inserting the button head into the formwork and driving the wedge into the button head using a hammer, a robust connection is created. 5. Cone Ties: Similar to snap ties, cone ties possess a cone-shaped head instead of a button head. The cone head is inserted into the formwork, and a metal wedge is driven into the cone, securing the formwork. 6. Waler Ties: Waler ties connect horizontal waler beams with vertical formwork members, enhancing the strength and stability of the formwork system. 7. Loop Ties: Made of steel wire, loop ties feature loops on both ends. They are employed to fasten wall forms together and can be effortlessly removed once the concrete has cured. 8. Pin and Wedge Ties: Pin and wedge ties comprise a pin and a wedge. The pin is inserted into the formwork, and the wedge is driven into the pin, creating a tight and secure connection. These examples represent only a fraction of the form ties available for steel formwork. The selection of a tie depends on factors such as construction type, desired strength, ease of installation, and specific project requirements.

- Q: How does steel formwork help in achieving accurate dimensions and shapes?

- Steel formwork helps in achieving accurate dimensions and shapes by providing a strong and rigid structure that holds the concrete in place during the curing process. This prevents any movement or deformation of the concrete, ensuring that it sets in the desired shape and size. The precise fabrication and assembly of steel formwork also allow for easy adjustment and customization, enabling accurate measurements and achieving the desired dimensions of the final structure.

- Q: How does steel formwork perform in seismic-prone areas?

- Due to its inherent strength and durability, steel formwork performs exceptionally well in seismic-prone areas. Unlike timber or plywood formwork, steel formwork offers superior resistance to seismic forces, providing a rigid and stable structure capable of withstanding lateral forces generated during an earthquake. One of the main advantages of using steel formwork in seismic-prone areas is its ability to maintain structural integrity and stability. The high tensile strength of steel enables it to resist the powerful shaking and ground motions associated with seismic activity. As a result, steel formwork is less likely to deform, crack, or collapse during an earthquake, ensuring the safety of both the structure and the construction workers. Additionally, steel formwork possesses excellent load-bearing capacity, which is crucial in seismic-prone areas. The formwork system provides robust support to the concrete during casting and curing, ensuring the structure remains intact even under dynamic loading conditions. This ability to withstand heavy loads is particularly important in earthquake-resistant design, as it helps prevent structural failure and the resulting loss of life and property. In addition to its strength, steel formwork offers other advantages in seismic-prone regions. It is highly reusable, durable, and resistant to moisture, making it ideal for construction projects in areas with high seismic activity. The reusability of steel formwork reduces construction waste and allows for long-term cost savings. Furthermore, steel formwork is versatile and adaptable, making it suitable for various structural applications in seismic-prone areas. It can be easily customized to fit different shapes and sizes, facilitating the efficient construction of complex structures. This flexibility is crucial in earthquake-resistant design, where the formwork must conform to specific architectural and structural requirements. Overall, steel formwork is an excellent choice for construction in seismic-prone areas. Its strength, durability, load-bearing capacity, reusability, and adaptability make it a reliable and efficient solution for withstanding the forces exerted by earthquakes. By utilizing steel formwork, construction projects can enhance the safety and resilience of structures in regions prone to seismic activity.

- Q: How does steel formwork compare to wooden formwork in terms of cost?

- Steel formwork generally tends to be more expensive than wooden formwork in terms of upfront costs. This is mainly due to the higher cost of materials and manufacturing processes involved in producing steel formwork. Additionally, steel formwork often requires specialized equipment and skilled labor for installation, which can further contribute to its higher cost. On the other hand, wooden formwork is typically more affordable in terms of initial investment. Wood is widely available and relatively inexpensive compared to steel. Furthermore, wooden formwork can be easily fabricated and customized on-site, reducing the need for additional expenses associated with specialized manufacturing. However, it is important to consider the long-term costs when comparing steel and wooden formwork. Steel formwork has the advantage of being more durable and resilient to wear and tear. It can withstand multiple uses and is less susceptible to damage from moisture, insects, and other environmental factors. This means that steel formwork can be used repeatedly, reducing the need for frequent replacement and lowering long-term costs. Wooden formwork, on the other hand, may require regular maintenance, repairs, and eventual replacement due to its susceptibility to damage and deterioration over time. This can result in additional costs over the lifespan of the project. In conclusion, while steel formwork may be initially more expensive than wooden formwork, its durability and longevity can lead to cost savings in the long run. However, the choice between steel and wooden formwork ultimately depends on the specific project requirements, budget, and other factors such as time constraints and availability of resources.

- Q: How does steel formwork contribute to improved construction efficiency?

- Improved construction efficiency can be achieved through the use of steel formwork, which offers various advantages. To begin with, steel formwork stands out for its durability and strength. It has the ability to withstand heavy loads and extreme weather conditions, enabling construction projects to proceed without interruptions. As a result, builders can work more quickly and efficiently. Furthermore, steel formwork is reusable, unlike traditional timber formwork that often needs to be replaced after a few uses. This reduces the need for constant material replenishment, saving time, cutting down on construction costs, and minimizing waste. Moreover, steel formwork provides excellent dimensional accuracy and stability. It allows for precise shaping and alignment of concrete structures, guaranteeing that they meet the required specifications and standards. This accuracy eliminates the need for rework or adjustments, saving time and resources. In addition, steel formwork is easy to assemble and dismantle due to its modular design. This facilitates quick installation and removal, reducing the time spent on formwork-related activities. This aspect is particularly advantageous for large-scale projects where time is of the essence. Furthermore, steel formwork produces a smooth and even finish on concrete structures, eliminating the need for additional plastering or finishing work. This further enhances construction efficiency. Additionally, the smooth surfaces created by steel formwork are easier to clean and maintain, ensuring a longer lifespan for the structure. Lastly, steel formwork enhances the safety of construction workers. Its strength and stability minimize the risk of accidents or collapses, creating a secure working environment. This, in turn, boosts productivity and efficiency on the construction site. To summarize, the use of steel formwork improves construction efficiency by providing durability, reusability, dimensional accuracy, quick assembly, smooth finishes, and enhanced safety. These factors allow construction projects to progress more rapidly, reduce costs, and deliver high-quality structures within the desired timeframe.

- Q: How does steel formwork contribute to the overall sustainability of a structure?

- Steel formwork contributes to the overall sustainability of a structure in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions and resist corrosion. This means that steel formwork can be reused multiple times, reducing the need for new formwork to be manufactured for each construction project. By reducing the demand for new materials, steel formwork helps to conserve natural resources and minimize the environmental impact associated with the extraction and production of new materials. Additionally, steel formwork allows for efficient and precise construction processes. Its strength and rigidity enable it to support heavy loads and provide stability during concrete pouring. This facilitates faster construction time, reducing labor costs and minimizing the use of construction equipment. The efficiency and precision provided by steel formwork contribute to the overall sustainability of a structure by conserving energy and reducing waste. Moreover, steel formwork is a versatile and flexible option that can be easily adjusted or modified to meet changing construction needs. This adaptability allows for the reuse of formwork in different projects, reducing the amount of waste generated. Furthermore, steel formwork can be recycled at the end of its lifespan, contributing to the circular economy by reducing landfill waste and minimizing the environmental impact associated with disposal. Overall, steel formwork promotes sustainability in construction by reducing the need for new materials, conserving energy, minimizing waste, and facilitating efficient construction processes. Its durability, reusability, adaptability, and recyclability make it an environmentally friendly choice that contributes to the long-term sustainability of structures.

- Q: Can steel formwork be used in high-temperature environments?

- No, steel formwork is not suitable for use in high-temperature environments. Steel has a high coefficient of thermal expansion, meaning it expands significantly when exposed to high temperatures. This expansion can lead to warping, distortion, and even structural failure of the formwork. Additionally, steel can lose its strength and load-bearing capacity at elevated temperatures, making it unsafe for use in high-temperature environments. It is recommended to use alternative formwork materials such as heat-resistant plastics or composite materials that are specifically designed for high-temperature applications.

- Q: What are the different types of joints used with steel formwork?

- Steel formwork joints in construction projects can be categorized into different types, each serving a specific purpose. These joints are crucial for ensuring stability, strength, and ease of assembly and disassembly. Here are some commonly used joints: 1. Straight Sections: For connecting straight sections of formwork, a simple butt joint is employed, where the edges of two steel formwork sections are placed together. 2. Longer Sections: To provide additional strength for longer sections of formwork, a lap joint is used. In this joint, one formwork section overlaps another, creating a strong connection. 3. Adjustable and Repositionable: A clamped joint utilizes clamps or bolts to securely fasten the formwork sections together. This joint allows for easy adjustment and repositioning of the formwork. 4. Vertical and Horizontal Connections: A wedge joint is commonly used to connect vertical and horizontal formwork sections. It involves inserting a wedge-shaped piece into a slot to create a secure connection. 5. Large and Heavy Components: A flanged joint is created by using flanges or plates on the formwork sections, which overlap and are bolted together. This joint provides a strong connection and is ideal for large and heavy formwork components. 6. Quick Assembly and Disassembly: For quick and easy assembly and disassembly of formwork sections, a pin joint is utilized. Pins or dowels are used to connect the formwork sections securely. Selecting the appropriate joint type is essential and should be based on the specific requirements of the construction project. Factors such as formwork design, load-bearing capacity, ease of assembly, and reusability are crucial in determining the suitable joint choice.

- Q: Can steel formwork be used for precast concrete facades?

- Yes, steel formwork can be used for precast concrete facades. Steel formwork provides a strong and durable framework for casting precast concrete panels and is commonly used in the construction industry for various applications, including facades. It offers the advantage of being reusable, allowing for cost savings and faster construction times. Additionally, steel formwork can be easily customized to create intricate designs and complex shapes, making it a suitable choice for precast concrete facades.

- Q: How does steel formwork affect the overall fire resistance of a building?

- Steel formwork does not directly affect the overall fire resistance of a building. Fire resistance in a building is primarily determined by the materials used for structural components such as columns, beams, and floors. However, steel formwork can indirectly impact the fire resistance of a building in a few ways. Firstly, steel formwork is often used for constructing concrete structures. Concrete itself has good fire resistance properties, as it is a non-combustible material. When steel formwork is used to mold concrete, it helps create a fire-resistant structure by providing a strong and durable framework for the concrete to be poured into. This ensures that the structure will remain intact under high temperatures and prevent the collapse of the building during a fire. Secondly, steel formwork can also contribute to the fire resistance of a building through its ability to withstand high temperatures. Unlike other types of formwork materials, such as wood or plastic, steel formwork is less susceptible to burning or melting. This means that even in the event of a fire, the steel formwork will not contribute to the spread of flames or release toxic fumes, which can help to contain the fire and minimize its impact on the overall fire resistance of the building. Lastly, steel formwork can also indirectly affect the fire resistance of a building by facilitating the installation of fire protection measures. Steel formwork provides a smooth and sturdy surface, allowing for the easy application of fire-resistant coatings, such as intumescent paint or fireproof sprays. These coatings enhance the fire resistance of the structure by providing an additional layer of protection against heat transfer and fire spread. In summary, while steel formwork itself does not directly impact the fire resistance of a building, it plays a crucial role in creating a fire-resistant structure by providing a strong framework for concrete, withstanding high temperatures, and facilitating the installation of fire protection measures.

Send your message to us

Climbing-Bracket CB 210 for formwork and scaffolding system

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 1000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches