China T-One Aluminum Extrusion Profiles for Sliding Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum Profile Sliding Windows and Doors Made in China

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminum Profile Sliding Windows and Doors Made in China

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminum Profile Sliding Windows and Doors Made in China

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

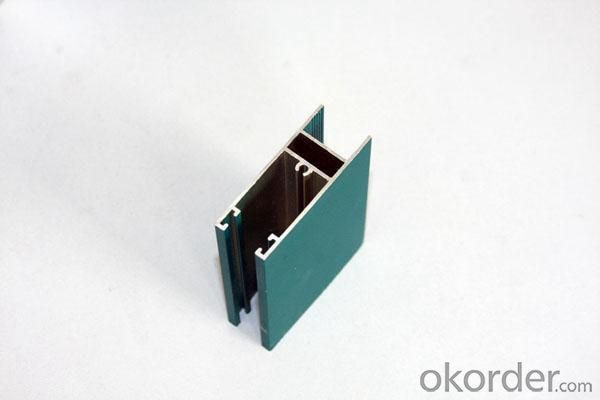

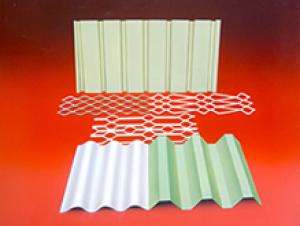

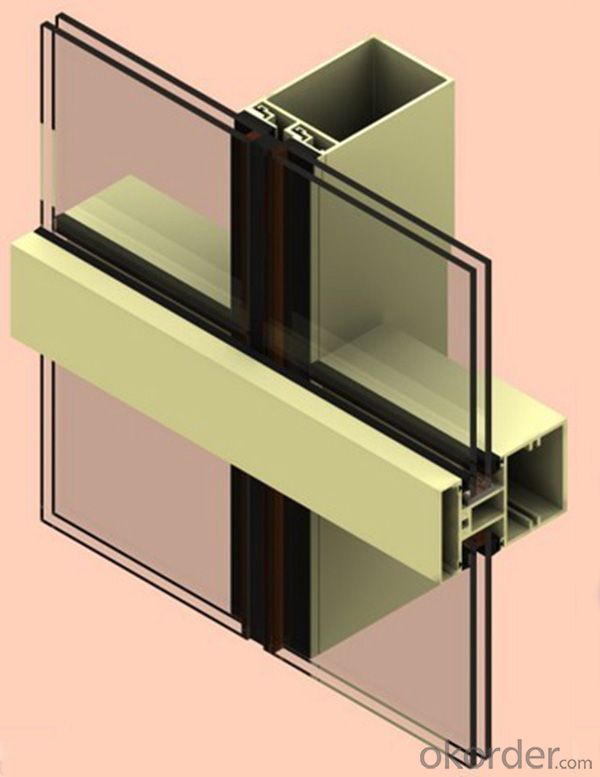

5. Image of Aluminum Profile Sliding Windows and Doors Made in China

6. Package and shipping of Aluminum Profile Sliding Windows and Doors Made in China

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles possess commendable heat resistance properties, as they possess a relatively high melting point of 660.3°C (1220.5°F) and demonstrate a low coefficient of thermal expansion. These characteristics enable aluminum profiles to endure elevated temperatures without experiencing notable distortion or structural harm. Consequently, aluminum profiles are well-suited for diverse applications that demand heat resistance, including heat sinks, automotive components, and industrial equipment. Furthermore, aluminum's exceptional thermal conductivity facilitates effective dissipation of heat, further augmenting their performance in environments characterized by high levels of heat. Nevertheless, it is imperative to acknowledge that aluminum's heat resistance does not match the level of certain other metals like steel or titanium, thereby necessitating the consideration of alternative materials in exceedingly high-temperature scenarios.

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Hello, I do not know if you have any requirements to the region, if not, you can consider the manufacturers here in Foshan?Industrial aluminum extrusion machine operation rules and precautions (looking for aluminum profiles manufacturers search: "Foshan bright silver custom")First from the process analysis:1. open aluminum extrusion machine, must ensure that equipment around and on the machine no debris, oil2. prepare the material according to the production request, and then pour into the tank according to the proportion3. check the power status and acknowledge the normal operation of the control cabinet

- Q: This question asks about the various types of aluminum profiles that are utilized in the construction of insulation systems.

- <p>Aluminum profiles used for building insulation come in various types, each serving specific functions. These include: 1. Insulation profiles, which provide a thermal barrier; 2. Structural profiles, used for structural support; 3. Cover profiles, which protect the insulation material; 4. Joint profiles, used for sealing joints; 5. Corner profiles, for reinforcing corners; 6. Edge profiles, for finishing edges; and 7. Special profiles, designed for specific applications. Each type is engineered to enhance thermal efficiency and structural integrity in building insulation systems.</p>

- Q: How do aluminum profiles contribute to lightweight construction?

- Aluminum profiles contribute to lightweight construction by being strong and durable while also being significantly lighter in weight compared to other materials. This allows for the creation of structures that are both robust and easy to handle, reducing the overall weight of the construction. Additionally, aluminum profiles can be easily shaped and joined together, enabling designers to create complex and innovative lightweight designs.

- Q: This question asks for a method to determine the quantity of aluminum profiles required for a construction project.

- <p>To calculate the amount of aluminum profiles needed for a building project, follow these steps: 1. Determine the design specifications and dimensions of the project, including the length, width, and height of the structure. 2. Identify the types and sizes of aluminum profiles required based on the structural needs and design. 3. Calculate the total linear footage of each profile type needed by multiplying the length of each required section by the number of sections. 4. Add up the total linear footage for all profile types. 5. Account for waste and cutting losses, typically adding 5-10% to the total. 6. Ensure the calculations comply with building codes and safety standards. Consult with engineers or architects if necessary.</p>

- Q: Features of aluminum profiles

- Corrosion resistanceThe density of aluminum profile is only 2.7g/cm3, about 1/3 of steel, copper or brass (7.83g/, cm3, 8.93g/, cm3), respectively. Aluminum can show excellent corrosion resistance in most ambient conditions, including air, water (or brine), petrochemical, and many chemical systems nductivityAluminum profile is often chosen because of its excellent electrical conductivity. On the basis of equal weight, the conductivity of aluminum is nearly two times that of copper.

- Q: What are the different types of anodizing options for aluminum profiles?

- There are several types of anodizing options for aluminum profiles, including sulfuric acid anodizing (SAA), chromic acid anodizing (CAA), hard anodizing, and two-step anodizing. SAA is the most common type, providing a durable and corrosion-resistant finish. CAA offers a thinner and less durable coating, but it is commonly used for aerospace applications. Hard anodizing produces a thicker and harder coating, ideal for high-wear applications. Two-step anodizing involves an additional coloring process, allowing for a wide range of decorative finishes.

- Q: Can aluminum profiles be used in load-bearing structures?

- Yes, aluminum profiles can be used in load-bearing structures. Aluminum is a lightweight and highly durable material that possesses excellent strength-to-weight ratio, making it suitable for various load-bearing applications. The profiles can be designed and manufactured to handle substantial loads, making them ideal for use in structures such as bridges, buildings, and industrial frameworks. Moreover, aluminum profiles have corrosion-resistant properties, which further enhances their suitability for load-bearing structures in various environments. However, it is essential to consider the specific design requirements, load conditions, and proper engineering calculations to ensure the aluminum profiles are appropriately sized and reinforced for the intended load-bearing purposes.

- Q: How about the price of aluminum profile?

- Usually calculated by weight, or by weight according to the length of each metre.

- Q: Can aluminum profiles be used in the production of automotive interiors?

- Yes, aluminum profiles can be used in the production of automotive interiors. Aluminum is a lightweight and durable material that offers numerous advantages for automotive applications. It is highly resistant to corrosion, which is essential for withstanding the harsh conditions within vehicles. Aluminum profiles can be used to create various components in automotive interiors, such as door panels, instrument panels, seat frames, and trim pieces. Additionally, aluminum profiles can be easily formed and shaped to meet specific design requirements, allowing for flexibility in automotive interior design. The use of aluminum profiles in automotive interiors can help reduce the overall weight of the vehicle, resulting in improved fuel efficiency and reduced emissions.

Send your message to us

China T-One Aluminum Extrusion Profiles for Sliding Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords