China Aluminum Coil - Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx, 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

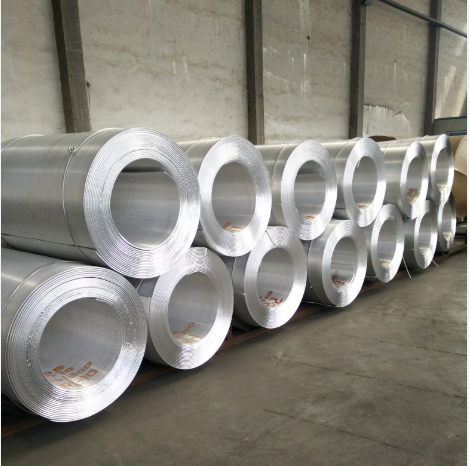

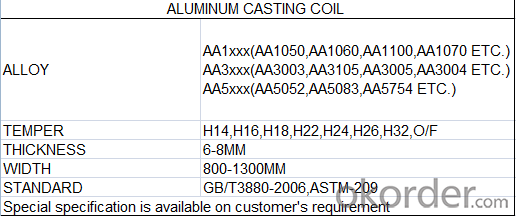

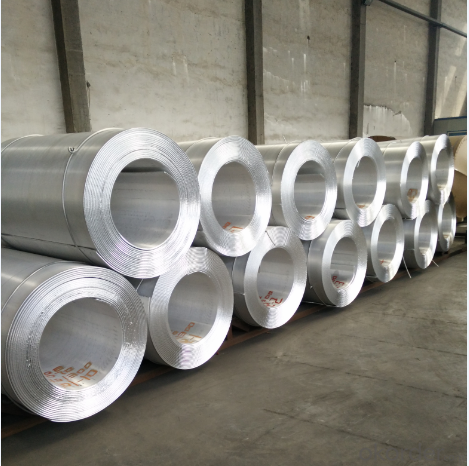

1.Structure of Aluminum Master Casting Coil 6-8mm in Alloys:

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Master Casting Coil 6-8mm in alloys:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

3. Aluminum Master Casting Coil 6-8mm in Alloys

4. Production Process of Aluminum Master Casting Coil 6-8mm in Alloys

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Master Casting Coil 6-8mm in Alloys

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: How to pull the aluminum coil purchased into aluminum sheet?

- You can buy flat sheet directly next time to avoid trouble.

- Q: Are aluminum coils suitable for coil slitting applications?

- Yes, aluminum coils are suitable for coil slitting applications. Aluminum is a versatile and lightweight material that can be easily processed and slit into various widths, making it ideal for industries like automotive, construction, and packaging. Its high strength-to-weight ratio and corrosion resistance make aluminum coils a reliable choice for coil slitting applications.

- Q: what is aircraft grade aluminum?

- Military Grade Aluminum

- Q: How do aluminum coils perform in cryogenic environments?

- Aluminum coils perform well in cryogenic environments due to their low thermal expansion coefficient and high thermal conductivity. These properties allow the coils to withstand extreme cold temperatures without warping or losing efficiency. Additionally, aluminum's corrosion resistance ensures the longevity and reliability of the coils in such environments.

- Q: What are the different width tolerances for aluminum coils?

- The width tolerances of aluminum coils may differ based on specific requirements and industry standards. Typically, the range of tolerances is between +/- 0.005 inches and +/- 0.25 inches. Nevertheless, the intended use of the aluminum coils may necessitate stricter requirements or more lenient tolerances in certain applications. To ascertain the precise width tolerances for a particular application, it is vital to refer to the manufacturer's specifications and guidelines or industry standards.

- Q: How are aluminum coils annealed?

- Aluminum coils undergo a heat treatment process called annealing, which is typically used to soften the metal and enhance its ductility. This process involves heating the coils to a specific temperature and gradually cooling them. To start the annealing of aluminum coils, thorough cleaning is required to eliminate any impurities. Then, the coils are placed in a furnace that is heated to the desired temperature. The duration and temperature of the annealing process depend on the specific grade and thickness of the aluminum being treated. Once the coils reach the desired temperature, they are maintained at that level for a specific period. This allows the internal structure of the aluminum to become more uniform and relieves any internal stresses that may have occurred during manufacturing. After completion of the annealing process, the coils are slowly cooled within the furnace. This gradual cooling is crucial to prevent the development of new internal stresses. Once the coils reach room temperature, they are ready for further processing or utilization. In some instances, an additional process called quenching may follow annealing. Quenching involves rapidly cooling the aluminum by immersing it in a medium like water or oil. This can further enhance the mechanical properties of the aluminum, such as its strength and hardness. Overall, the annealing process for aluminum coils is a meticulously controlled heat treatment that aims to enhance the metal's properties and make it more suitable for various applications.

- Q: This question asks about the impact of aluminum coils on the quality of welding. It seeks to understand the relationship between the material properties of aluminum coils and the outcomes of the welding process.

- <p>Aluminum coils can significantly affect welding quality due to their unique properties. Aluminum has a high thermal conductivity, which requires more energy to weld, and can lead to rapid heat dissipation, affecting the weld's uniformity. Oxides on the aluminum surface can also interfere with the welding process, causing porosity and poor joint strength if not properly cleaned. Additionally, aluminum's low melting point can lead to distortion and warping if not managed correctly. The use of appropriate filler materials, proper cleaning, and precise control of welding parameters are crucial to achieve high-quality welds with aluminum coils.</p>

- Q: What are the typical thickness tolerances for aluminum coils?

- The typical thickness tolerances for aluminum coils can vary depending on the specific manufacturing standards and requirements of the industry. However, in general, the thickness tolerances for aluminum coils range from +/- 0.001 to 0.005 inches. These tolerances ensure that the thickness of the aluminum coils remains within acceptable limits to meet the desired specifications and applications. It is important to note that the specific tolerances may differ based on the intended use of the aluminum coils, such as for architectural, automotive, or aerospace purposes.

- Q: What are the different types of aluminum coils available in the market?

- There are several different types of aluminum coils available in the market, each with its own unique characteristics and applications. 1. Plain Aluminum Coils: These are basic aluminum coils that are typically used for general applications. They have a smooth surface and are often used in construction, automotive, and packaging industries. 2. Color Coated Aluminum Coils: These coils are coated with a layer of paint or other finishes to enhance their aesthetic appeal and provide additional protection against corrosion. They are commonly used in the manufacturing of building facades, signage, and decorative applications. 3. Embossed Aluminum Coils: These coils have a textured or patterned surface, which gives them a decorative and non-slip finish. They are often used in applications where aesthetics and functionality are important, such as flooring, staircases, and decorative panels. 4. Anodized Aluminum Coils: These coils undergo an anodizing process, where a protective oxide layer is formed on the surface of the aluminum. This enhances their corrosion resistance and makes them suitable for outdoor applications, such as architectural elements, electronic components, and aerospace industry. 5. Pre-painted Aluminum Coils: These coils come with a pre-applied paint coating, which eliminates the need for additional painting or finishing. They are commonly used in industries that require high-quality, durable, and color-consistent products, such as automotive, appliances, and electronics. 6. Heat Exchanger Aluminum Coils: These coils are specifically designed for heat transfer applications, such as air conditioning and refrigeration systems. They have a high thermal conductivity and are often made from alloy grades that offer excellent corrosion resistance in harsh environments. It is important to consider the specific requirements and intended use of the aluminum coil before making a purchase. This will help ensure that the appropriate type of coil is selected for the desired application, thereby optimizing performance and longevity.

- Q: * How is hitting with a aluminum Wiffle Ball feel and work out?* Did you like the results you had hitting with a aluminum Wiffle Ball bat?

- I've used an aluminum Wiffle bat and it really feels a lot better to hit with than the yellow plastic number. The Aluminum bats are still super light, but there is a bit of weight to it, and that weight is kind of end-loaded, which you can really feel as you turn your wrists over. The net result is a swing that feels more like a real bat with the barrel whipping through the hitting zone instead of that flyswatter feel you get with the regular bats. Oh, and you definitely get more distance when you connect. Definitely. I actually played in a Wiffle Ball tournament a few years ago and used those bats. Someone said that they no longer make them or they've been outlawed or something along those lines.

Send your message to us

China Aluminum Coil - Aluminum Master Casting Coil 6-8mm in Alloys 1xxx, 3xxx, 5xxx

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords