1100 Aluminum Coil - Aluminum Continuous Coil (Alu CC Coil)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Why we use aluminum?

In Europe aluminium experiences high rates of recycling, ranging from 42% of beverage cans, 85% of

construction materials and 95% of transport vehicles.Recycled aluminium is known as secondary aluminium, but maintains the same physical properties as primary aluminium. Secondary aluminium is produced in a wide range of formats and is employed in 80% of alloy injections. Another important use is for extrusion.

White dross from primary aluminium production and from secondary recycling operations still contains useful quantities of aluminium that can be extracted industrially.The process produces aluminium billets, together with a highly complex waste material. This waste is difficult to manage. It reacts with water, releasing a mixture of gases (including, among others, hydrogen, acetylene, and ammonia), which spontaneously ignites on contact with air;contact with damp air results in the release of copious quantities of ammonia

gas. Despite these difficulties, the waste has found use as a filler in asphalt and concrete.

2.Specification and Application

ALUMINIUM COIL

ALLOY: AA1***

AA3***

AA5***

AA8***

TEMPER: H14 H16 H18 H22 H24 H26 H32 O/F

THICKNESS:0.03MM-10MM

WIDTH: 30MM-1700MM

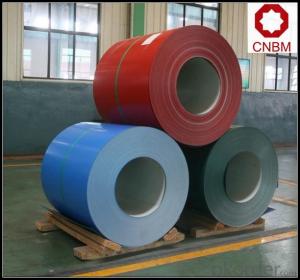

COATING: PE(POLYESTER),PVDF,EPOXY or Mill Finished.

STANDARD: GB/T 17748-1999

3.Why you choose us?

Our company promise the best quality, best service and best price.Welcome you to visit our factory!

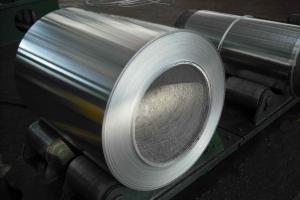

4.Pictures

5.FAQ:

1)what is aluminum?

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, nonmagnetic, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface.

Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

2)What's kind of payment term we can supply?

CIF,CFR, FOB and other.

3)Can we supply samples?

Yes, we can!

4)What can you do if you have other quastions?

You can contact us freely at any time!

2)How about our payment term?

LC and TT and other.

3)Which country can we supply?

All around the world!

- Q: Can aluminum coils be used in electrical applications?

- Indeed, aluminum coils possess the capability for utilization in electrical applications. Its abundance in electrical wiring is attributable to its cost-effectiveness and superior conductivity in comparison to copper. Transformers, motors, generators, and other electrical apparatuses commonly rely on aluminum coils. Nevertheless, it is essential to acknowledge that copper surpasses aluminum in terms of electrical conductivity, necessitating the use of larger aluminum coils to attain equivalent levels of conductivity. Moreover, the implementation of specialized insulation and connectors becomes imperative for aluminum coils to prevent corrosion and guarantee appropriate electrical connections.

- Q: This question asks for a comparison of various types of insulation materials, highlighting their unique characteristics and differences.

- <p>Different types of insulation materials vary in their properties such as thermal resistance (R-value), fire resistance, moisture resistance, and environmental impact. Fiberglass is a common, cost-effective option with good thermal resistance but can be irritating to the skin and respiratory system. Cellulose insulation is made from recycled paper and has good sound absorption but may be less fire resistant. Foam insulation like spray foam offers excellent insulation and air sealing but can be more expensive and harder to install. Mineral wool is fire-resistant and durable but may be less thermally efficient. Each type has its advantages and drawbacks, and the choice depends on factors like cost, environmental impact, and specific insulation needs.</p>

- Q: What are aluminum coils?

- Aluminum coils, wound in a spiral shape, are thin and flat pieces of aluminum. Their versatility and durability make them commonly utilized in various industries. These coils are typically crafted from high-quality aluminum alloy, which grants them qualities such as lightweight, corrosion resistance, and ease of manipulation. A wide range of applications, including building and construction, automotive manufacturing, electrical appliances, and packaging, benefit from the use of aluminum coils. Depending on the specific requirements of the industry or product, these coils can be further processed into different forms, such as sheets, foils, or strips. Altogether, aluminum coils are crucial components in numerous manufacturing processes and play an essential role in diverse industries.

- Q: Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a commonly used material in solar panel manufacturing due to its lightweight, corrosion resistance, and high thermal conductivity properties. It is often used as a backing material for solar cells and as a component in the frame or structure of the solar panel.

- Q: is Aluminum wrotten with a 2 behnd it?

- Aluminum is not a diatomic atom, which is to say, in it's equilibrium state it has only one atom, written Al. As an ion, aluminum has a charge of 3+, and may have a subscript of 2 when written in an ionic formula (i.e., aluminum oxide: Al2O3).

- Q: What are the different types of end conditions for aluminum coils?

- The different types of end conditions for aluminum coils include plain end, slit end, trimmed end, and sheared end.

- Q: What are the common testing methods for aluminum coils?

- There are several common testing methods for aluminum coils that are used to ensure their quality and performance. These methods include: 1. Visual inspection: This involves a thorough examination of the coils for any visible defects such as dents, scratches, or surface irregularities. Visual inspection is a basic and initial step in the testing process. 2. Dimensional measurement: This method involves measuring the dimensions of the aluminum coils to ensure they meet the specified requirements. This includes measuring the length, width, and thickness of the coils. 3. Tensile testing: Tensile testing is performed to assess the mechanical properties of the aluminum coils, such as their strength and elasticity. This test involves applying a tensile force to a sample of the coil until it breaks or deforms, allowing for the determination of its tensile strength. 4. Hardness testing: The hardness of aluminum coils is an important factor in determining their suitability for specific applications. Various hardness testing methods, such as Rockwell or Brinell hardness tests, can be used to measure the resistance of the coil's surface to indentation or scratching. 5. Chemical composition analysis: This method involves analyzing the chemical composition of the aluminum coil to ensure it meets the required specifications. Common techniques used for this analysis include spectroscopy or X-ray fluorescence (XRF) analysis. 6. Corrosion resistance testing: Aluminum coils are often exposed to harsh environmental conditions, so assessing their resistance to corrosion is crucial. This can be done through various tests like salt spray testing or electrochemical impedance spectroscopy (EIS) to determine the coil's ability to withstand corrosion. 7. Coating quality assessment: If the aluminum coil is coated with a protective layer, testing methods such as adhesion testing, coating thickness measurement, or impact resistance testing can be used to ensure the quality and durability of the coating. These are some of the most common testing methods employed for aluminum coils. By conducting these tests, manufacturers can ensure that the coils meet the required standards and perform optimally in their intended applications.

- Q: This question asks for the weight of a single layer of an aluminum coil, which can vary based on its dimensions.

- <p>The weight of a single layer of an aluminum coil depends on its thickness, width, and length. To calculate the weight, you can use the formula: weight = volume 脳 density. The density of aluminum is approximately 2.7 grams per cubic centimeter. If you know the dimensions of the coil, you can calculate its volume and then multiply by the density to find the weight. For example, if the coil has a thickness of 0.1 mm, a width of 1 meter, and a length of 100 meters, the volume would be 0.1 liters or 100 cubic centimeters, and the weight would be approximately 270 kg. However, without specific dimensions, it's impossible to provide an exact weight.</p>

- Q: How are aluminum coils used in signage and advertising?

- Aluminum coils are commonly used in signage and advertising as a durable and lightweight material for creating various types of signs. These coils can be easily shaped, cut, and bent to form letters, logos, and other designs. Their corrosion-resistant properties make them suitable for outdoor use, ensuring longevity and durability. Additionally, aluminum coils are often coated or painted to enhance their aesthetic appeal and provide a smooth and polished finish. This versatility and flexibility make aluminum coils a popular choice for creating eye-catching and long-lasting signs and advertisements.

- Q: Can aluminum coils be used in the manufacturing of aircraft parts?

- Yes, aluminum coils can be used in the manufacturing of aircraft parts. Aluminum is a lightweight and durable material that is widely used in the aerospace industry due to its high strength-to-weight ratio and corrosion resistance. The coils can be formed and machined into various components such as fuselage skins, wings, and structural frames, making them an ideal choice for aircraft manufacturing.

Send your message to us

1100 Aluminum Coil - Aluminum Continuous Coil (Alu CC Coil)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords