1100 Aluminum Coil Price Non-Stick Round Aluminum Circle Disk for Utensils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

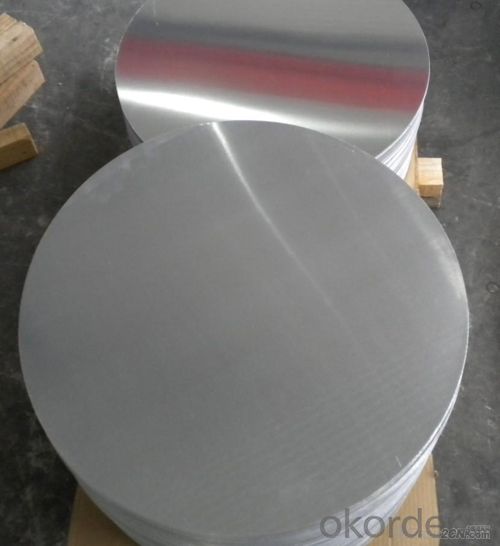

1. Description of Non-Stick Round aluminum Circle Disk for Utensils

Alloy: 1050, 1070, 1100, 3003, etc

Thickness: 0.5mm~4mm

Temper: O, H14

Diagonal: 100mm - 1200mm

2. Application of Non-Stick Round aluminum Circle Disk for Utensils

Aluminium Circle is widely used for kitchen wares including fried pans, non-sticky pans, cooking pots, hard anodize cook ware, pressure cooker and house hold utensils etc.

3. Feature of Non-Stick Round aluminum Circle Disk for Utensils

Aluminium Circle has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Non-Stick Round aluminum Circle Disk for Utensils

6. Package and shipping of Non-Stick Round aluminum Circle Disk for Utensils

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the common sizes and thicknesses of aluminum coils?

- The sizes and thicknesses of aluminum coils differ depending on the application and industry. However, there are standard sizes and thicknesses that are commonly utilized across various industries. Regarding size, aluminum coils typically span from approximately 12 to 72 inches in width. This range allows for adaptability in accommodating diverse production processes and equipment. The length of the coils can also vary, but it often falls within the 1000 to 6000 feet range. Concerning thickness, aluminum coils are available in different gauges, typically measured in inches or millimeters. The most frequently employed thicknesses for aluminum coils range from 0.019 inches (0.48 mm) to 0.125 inches (3.18 mm). These thicknesses are suitable for a broad array of applications, including roofing, construction, automotive, and manufacturing. It is important to note that these are general guidelines, and the specific requirements for size and thickness may differ depending on the intended use of the aluminum coils. Additionally, custom sizes and thicknesses can also be manufactured to fulfill specific project requirements.

- Q: How are aluminum coils tested for surface roughness?

- Various methods are employed to test the surface roughness of aluminum coils, guaranteeing that they meet the necessary quality standards. One frequently utilized technique involves the utilization of a surface roughness tester or profilometer. This device gauges the roughness of the coil surface by tracing a stylus or probe across it and recording the height variations. The surface roughness tester furnishes data such as Ra (average roughness), Rz (average peak-to-valley roughness), and Rt (total height roughness). These parameters aid in evaluating the surface quality of the aluminum coil and ascertaining whether it adheres to the desired specifications. Additionally, visual inspection is commonly performed to identify any visible defects, scratches, or irregularities on the surface. This inspection can be carried out manually by trained operators or with the assistance of automated systems that employ cameras and image analysis algorithms to detect imperfections. Another method utilized to assess surface roughness involves the use of laser scanners. These scanners emit laser beams that bounce off the surface of the aluminum coil and are subsequently measured to determine the surface profile and roughness. Laser scanners offer high-resolution, contactless measurements, rendering them highly accurate and efficient for evaluating surface roughness. All in all, a combination of surface roughness testers, visual inspection, and laser scanners are typically employed to test the surface roughness of aluminum coils, guaranteeing that they meet the necessary quality standards for diverse applications.

- Q: What is the structure of Aluminium Chloride at 180, 192.4 (melting point) and 200 degrees celsius? When does it exist as an ionic lattice and when as a Al2Cl6 dimer?

- Aluminium chloride sublimes (turns straight from a solid to a gas) at about 180°C. If it simply contained ions it would have a very high melting and boiling point because of the strong attractions between the positive and negative ions. The implication is that it when it sublimes at this relatively low temperature, it must be covalent. The dots-and-crosses diagram shows only the outer electrons. Hope that help Check here for more information; www.chemguide .uk/atoms/bonding...

- Q: What are the common handling and storage practices for aluminum coils?

- The common handling and storage practices for aluminum coils include wearing protective gloves and eyewear when handling the coils to prevent injuries. It is necessary to handle the coils carefully and avoid dropping or dragging them to prevent damage. Additionally, coils should be stored in a dry and well-ventilated area to avoid moisture buildup and corrosion. They should be stacked on a flat and sturdy surface, with proper support and spacing between each coil to prevent deformation. Regular inspections and maintenance should be conducted to ensure the coils are stored and handled correctly.

- Q: What are the different sizes and dimensions of aluminum coils available?

- The sizes and dimensions of aluminum coils vary depending on the specific industry and application. Generally, aluminum coils are available in a range of widths, thicknesses, and lengths to accommodate various needs. In the construction industry, aluminum coils are commonly available in widths ranging from 24 inches to 60 inches. The thicknesses can range from 0.019 inches to 0.040 inches. The lengths of the coils can vary, but standard lengths are typically around 100 feet or more. For industrial and manufacturing purposes, the sizes and dimensions of aluminum coils can be even more diverse. Coils with widths exceeding 60 inches are available for large-scale applications. The thicknesses can range from 0.006 inches for thin, lightweight coils to 0.250 inches for heavy-duty applications. Additionally, the dimensions of aluminum coils can be customized to meet specific requirements. Some manufacturers offer coil slitting services to cut coils into narrower widths, while others can provide custom lengths or thicknesses based on the customer's specifications. It is important to note that the availability of different sizes and dimensions may vary among suppliers. Therefore, it is advisable to consult with a reputable aluminum coil supplier or manufacturer to determine the specific sizes and dimensions they offer.

- Q: Are there any limitations to the maximum coil diameter of aluminum coils?

- There exist limitations on the maximum coil diameter of aluminum coils. Factors such as the type and thickness of the aluminum, the coiling equipment, and the intended application of the coil determine the maximum coil diameter. Thinner and more ductile aluminum alloys generally allow for larger coil diameters. However, maintaining the structural integrity of the coil and preventing deformation, wrinkling, or damage during handling and transportation becomes increasingly challenging as the coil diameter increases. Moreover, the coiling equipment may have its own restrictions on the maximum diameter it can handle. Hence, it is crucial to take these factors into consideration when determining the maximum coil diameter for aluminum coils.

- Q: Are aluminum coils fire-resistant?

- Yes, aluminum coils are fire-resistant. Aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit) and it does not burn, making it a non-combustible material. This property makes aluminum coils suitable for various applications where fire resistance is a critical factor, such as in building construction, electrical wiring, and HVAC systems. Additionally, aluminum's excellent heat conductivity helps dissipate heat quickly, reducing the risk of fire. However, it is important to note that while aluminum coils themselves are fire-resistant, they may be used in systems that include other components which may not have the same level of fire resistance. It is important to consider the entire system and follow proper fire safety regulations and guidelines to ensure overall fire safety.

- Q: What are the typical thickness tolerances for aluminum coils?

- The typical thickness tolerances for aluminum coils can vary depending on the specific manufacturing standards and requirements of the industry. However, in general, the thickness tolerances for aluminum coils range from +/- 0.001 to 0.005 inches. These tolerances ensure that the thickness of the aluminum coils remains within acceptable limits to meet the desired specifications and applications. It is important to note that the specific tolerances may differ based on the intended use of the aluminum coils, such as for architectural, automotive, or aerospace purposes.

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

- Q: What are the elements and compounds that make up aluminum coils?

- <p>Aluminum coils are primarily composed of the element aluminum (Al), which is a lightweight, silvery-white, and ductile metal. Pure aluminum is relatively soft, so it is often alloyed with other elements to improve its strength and durability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. These elements can enhance properties like strength, formability, and resistance to corrosion. The specific composition of an aluminum coil can vary depending on the alloy type and the intended application, but the primary component will always be aluminum.</p>

Send your message to us

1100 Aluminum Coil Price Non-Stick Round Aluminum Circle Disk for Utensils

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords