Cheap Hot-dip Zinc Coating Steel JIS G3302 China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap Hot-dip Zinc Coating Steel JIS G3302 China

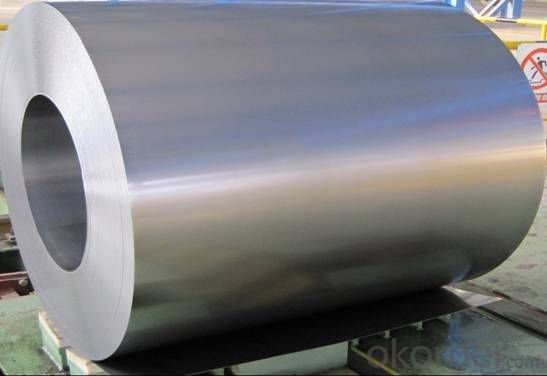

1.Structure of Cheap Hot-dip Zinc Coating Steel JIS G3302 China:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of Cheap Hot-dip Zinc Coating Steel JIS G3302 China:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Are steel coils used in HVAC systems?

- Yes, steel coils are commonly used in HVAC (Heating, Ventilation, and Air Conditioning) systems.

- Q: What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- The length of the roll is related to its width and thickness, but not to the extent of the zinc layer.

- Q: What are the different types of steel coatings used on coils?

- There are several types of steel coatings used on coils, including galvanized, galvannealed, and organic coatings. Galvanized coatings involve applying a layer of zinc to the steel surface, providing excellent corrosion resistance. Galvannealed coatings involve a two-step process where the steel is first galvanized and then heated to form an alloyed surface layer, offering enhanced paint adhesion and weldability. Organic coatings, on the other hand, use paints or other protective coatings to provide corrosion resistance and aesthetic appeal.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- It depends on the type of steel and how the wire was made (e.g. whether it was drawn hot or cold, whether it was heat treated after it was drawn, etc). For mild steel the elastic limit is about 400 MPa. Note this is not the same as the breaking stress for the wire which will typically be significantly higher for a ductile material like steel. If you want to measure a stress-strain curve to find youngs modulus, make sure you measure several points at stresses below the elastic limit - for example try increasing the stress in increments of about 50 MPa.

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various methods such as visual inspection, non-destructive testing techniques like ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These methods help identify surface defects, internal discontinuities, cracks, or other irregularities in the steel coils.

- Q: How are steel coils uncoiled?

- Steel coils are typically uncoiled using a machine called a decoiler or uncoiler, which gradually unwinds the coil by feeding it through a set of rollers. The rollers apply tension to the coil, allowing it to unwind smoothly and evenly. The speed and direction of the uncoiling process can be controlled to match the specific requirements of the application.

- Q: Describe and explain how the differences in the properties of the thee main types of steel allow them to be used in different ways. I have some chemistry homework due in for tomorrow (yes I know i left it a bit late but I really don't like chemistry) and I would love it if I could actually at least pretend to my teacher that I know what she's on about this lesson because honestly, I really don't know what she spends so long telling us all. Any help would be appreciated and points for the best answer!

- Hi, Three Main Types of Steel: 1. Carbon Steel Used in making axes, swords, scissors,cutting tools, vehicle frames. Depends on the % of carbon used how soft the steel will be. 2. Stainless Steel Used in the making of crockery, wrist watches, kitchen utensils, cutlery and surgical equipment. Contains different 11% chromium and some % of nickel. 3. Alloy Steel. Used in making drilling parts, vehicle airplane parts. Stainless steel is also alloy steel but, alloy steel with % of other metals is classified separately.

- Q: Hi all.I'm working on a project which requires about 3 steel pipes at 25mm in diametre and about a foot each in length.The qualities I need with the steel is that:1. I need it to be easy enough to weld together2. I need to be able to drill holes through them with a basic drill (I could buy different bits, that's fine)3. I need the steel to be able to take short intense repeated bursts of strain through said holes4. The lighter the steel the better5. Could I please have a ballpark figure for price. I can't imagine such a small amount of steel would cost too muchThank you in advance for your replyRegardsSean

- Call the steel pipe company or check their website

- Q: How do steel coils perform in corrosive environments?

- Steel coils exhibit excellent performance in corrosive environments due to their inherent resistance to corrosion. This is primarily because steel, being composed of iron and various elements like carbon, produces a protective layer called a passive film. This passive film acts as a barrier between the steel surface and corrosive elements, effectively preventing direct contact and minimizing the risk of corrosion. Moreover, steel coils can be coated with different protective coatings to enhance their corrosion resistance. Coatings like zinc or epoxy provide an additional layer of protection, significantly prolonging the lifespan of steel coils in corrosive environments. However, it is important to acknowledge that the performance of steel coils in corrosive environments can still be influenced by factors such as the type of corrosive agent, duration of exposure, and presence of other contaminants. In highly aggressive environments, such as those with high humidity, exposure to saltwater, or acidic chemicals, the protective layers on steel coils might deteriorate over time, thereby increasing the potential for corrosion. To ensure optimal performance in corrosive environments, it is advisable to choose steel coils with corrosion-resistant properties, such as stainless steel or galvanized steel. Regular maintenance and inspections are also crucial to promptly detect any signs of corrosion and implement appropriate measures to prevent further damage. In conclusion, steel coils generally exhibit good resistance to corrosion in most environments, but the severity of the corrosive conditions can ultimately impact their performance.

- Q: How are steel coils protected from mechanical damage?

- Steel coils are protected from mechanical damage through various methods such as using protective packaging materials like wooden crates or metal bands, applying plastic or paper interleaving, and utilizing specialized handling equipment during transportation and storage.

Send your message to us

Cheap Hot-dip Zinc Coating Steel JIS G3302 China

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords