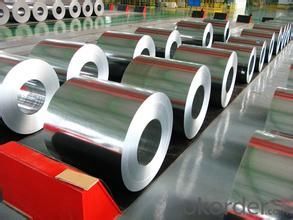

Cheap Hot-dip Zinc Coating Steel JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Cheap Hot-dip Zinc Coating Steel JIS G3302 China

Structure

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Main Features

• Excellent process capability

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.18mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Technology test results:

Processability | Yield strength | Tensile strength | Elongation % | 180°cold-bending |

Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: What is the role of steel coils in HVAC systems?

- Steel coils play a crucial role in HVAC (heating, ventilation, and air conditioning) systems as they are responsible for facilitating the transfer of heat between the air and the refrigerant. In HVAC systems, steel coils are typically used in two main components: the condenser coil and the evaporator coil. The condenser coil is located in the outdoor unit of an HVAC system and its primary function is to release the heat from the refrigerant into the surrounding air. This coil is made up of multiple steel tubes that are bent into a serpentine shape and are attached to aluminum fins. As the hot refrigerant flows through these tubes, the steel coils ensure maximum surface area contact with the surrounding air, allowing for efficient heat transfer. Through this process, the heat is dissipated into the outdoor environment, resulting in the cooling of the refrigerant. On the other hand, the evaporator coil is situated in the indoor unit of the HVAC system and its role is to absorb heat from the air inside the building. Similar to the condenser coil, the evaporator coil consists of steel tubes that are connected to aluminum fins. The refrigerant, in a cold state, flows through these tubes, and as warm air from the building passes over the coils, the heat is transferred from the air to the refrigerant. This heat absorption process cools down the air, which is then circulated back into the building, providing the desired cooling effect. Overall, steel coils in HVAC systems are essential for heat transfer between the air and the refrigerant. Their design and placement allow for efficient cooling or heating of the air, depending on the system's mode of operation. Without steel coils, HVAC systems would not be able to effectively regulate the temperature and provide the desired comfort levels in residential, commercial, and industrial buildings.

- Q: I am looking for a steel taper kit to help me start stretching my earlobes. I wanted something like the following but in steel instead of acrylic. Preferably something under $40 and from a reputable website. I don't know how much damage acrylic tapers can do in the few seconds it would be inside my earlobe, but I would rather use steel just to be safe. I will be forever grateful if anyone can help.

- All okorder /... This is the cheapest stainless steel taper kit i could fine. You can also use titanium and glass, but never use acrylic tapers because they're cheap, toxic and will give your ears that really nasty smell as you get into bigger gauges. I hoped i helped.

- Q: What are the dimensions of steel coils used in the agricultural equipment industry?

- The dimensions of steel coils utilized in the agricultural equipment sector differ based on the precise application and equipment requirements. Nevertheless, there are several prevalent dimensions for steel coils employed in this industry, spanning from 0.5mm to 6mm in thickness and 600mm to 2000mm in width. The length of the coils can be tailored to suit the particular equipment demands. Furthermore, the weight of the coils can fluctuate, generally ranging from a few hundred kilograms to multiple tons. It is crucial to acknowledge that these dimensions are not set in stone and may vary depending on the manufacturer and the specific agricultural equipment being manufactured.

- Q: i have a white spot on my stainless steel stove, its on the part behind the burners where the oven controls are, does anyone know what it may be and how to remove it. i have tried soap and water and stainless steel cleaner but neither worked. thanks!

- Baking soda mixed with liquid dish soap can make a good paste to gently rub on stains. Be sure to rinse the stainless steel surface thoroughly, and towel dry. If the stains still remain you can try vinegar. Remember to thoroughly rinse and towel dry. If stains still remain I recommend trying a stainless steel cleaner and polisher. Barkeeper's Friend is a good powder formula that can clean without scratching. Be sure to follow the directions, rinse thoroughly, and towel dry. These methods should help remove the discolorations

- Q: Is steel easier to weld?Which is more brittle/less flexible?

- Yes you can, but you really dont want to. Aluminum conducts heat better than steel so the weld would not cool evenly and would be brittle. You would be better off using a bracket or bolt straight on.

- Q: What are the dimensions of steel coils used in the pipeline industry?

- The dimensions of steel coils used in the pipeline industry vary depending on the specific requirements of the project. However, common dimensions for steel coils used in the pipeline industry range from 0.5 to 2 inches in thickness and 24 to 60 inches in width. The length of the coils can vary, but they are typically around 100 to 200 feet long.

- Q: How do steel coils contribute to the automotive aftermarket?

- Steel coils contribute to the automotive aftermarket by serving as a crucial raw material for manufacturing various components used in vehicles. These coils are responsible for providing strength, durability, and structural integrity to parts like body panels, chassis components, suspension systems, and exhaust systems. Additionally, steel coils are also used in the production of aftermarket accessories such as bumpers, grilles, and custom body kits. Their availability and versatility make steel coils an essential resource for the automotive industry, enabling the production of high-quality aftermarket products that enhance the performance and aesthetics of vehicles.

- Q: How are steel coils used in the manufacturing of construction materials?

- Steel coils are used in the manufacturing of construction materials as they are rolled into sheets or strips, which can then be shaped and formed into various structural components such as beams, columns, and frames. These coils provide the necessary strength and durability required for constructing buildings, bridges, and other infrastructure projects.

- Q: Can steel coils be coated with magnetic materials?

- Yes, steel coils can be coated with magnetic materials.

Send your message to us

Cheap Hot-dip Zinc Coating Steel JIS G3302

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords