CGCC PPGI Coils from CJC Steel Factory Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

CGCC PPGI Coils from CJC Steel Factory

Description of CGCC PPGI Coils from CJC Steel Factory

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of CGCC PPGI Coils from CJC Steel Factory

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

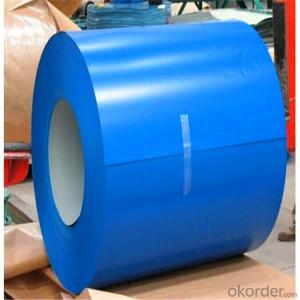

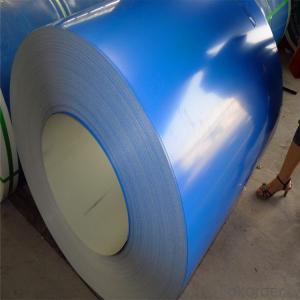

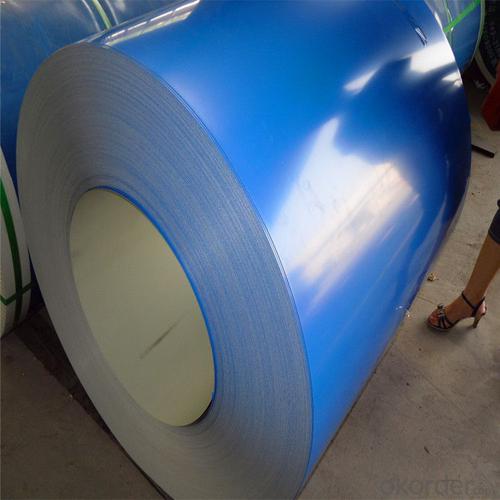

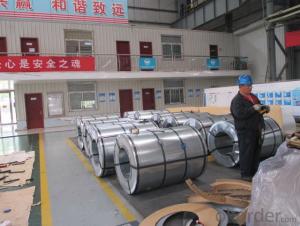

Products Show of CGCC PPGI Coils from CJC Steel Factory

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the common applications of stainless special steel?

- Stainless special steel is commonly used in a wide range of applications due to its unique properties and characteristics. Some of the most common applications include kitchenware and cookware, cutlery, medical equipment, automotive parts, aerospace components, construction materials, and various industrial machinery. Its corrosion resistance, high strength, durability, and aesthetic appeal make it a preferred choice in these industries.

- Q: What are the different powder coating techniques used for special steel?

- There are several powder coating techniques used for special steel, including electrostatic spray, fluidized bed, and flame spraying. Each technique offers unique advantages and is chosen based on factors such as the desired coating thickness, complexity of the surface, and specific properties required for the steel's functionality.

- Q: Can special steel be used in the sporting goods manufacturing industry?

- Yes, special steel can be used in the sporting goods manufacturing industry. Special steel alloys offer superior strength, durability, and corrosion resistance, which are crucial qualities for manufacturing various sporting goods such as golf clubs, bike frames, tennis rackets, and baseball bats. These alloys can be tailored to meet specific requirements, ensuring high performance and longevity in sports equipment.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its unique properties that make it highly resistant to deformation and fracture under high impact loads. The alloy steel's composition includes elements such as chromium, nickel, and molybdenum, which enhance its toughness and durability. These properties allow the alloy steel to absorb and disperse the energy generated during impact, effectively protecting the parts from damage. Additionally, the shock-resistant alloy steel's high strength enables it to withstand repeated impacts without losing its structural integrity, making it an ideal material for manufacturing impact-resistant parts used in various industries, including automotive, aerospace, and construction.

- Q: How is special steel produced?

- Special steel is typically produced through a combination of several processes, including melting, refining, casting, and heat treatment. It involves carefully selecting and blending various alloying elements to achieve desired chemical and mechanical properties. These elements are added to molten steel, which is then refined to remove impurities. The refined steel is then cast into various shapes and forms, such as bars, sheets, or tubes. Finally, the steel undergoes heat treatment processes like tempering or quenching to further enhance its strength and other properties.

- Q: What are the different heat treatment processes for special steel?

- There are several different heat treatment processes for special steel, including annealing, quenching, tempering, case hardening, and precipitation hardening.

- Q: How is alloy steel used in the production of gears and shafts?

- Alloy steel is commonly used in the production of gears and shafts due to its high strength, durability, and resistance to wear and fatigue. The addition of various alloying elements, such as chromium, nickel, and molybdenum, enhances the material's mechanical properties, making it suitable for heavy-duty applications. Alloy steel gears and shafts can withstand high loads, transmit torque efficiently, and provide reliable performance, ensuring smooth operation and prolonged lifespan in various industries, including automotive, aerospace, and manufacturing.

- Q: How is case-hardening steel used in the manufacturing of gears?

- Case-hardening steel is used in the manufacturing of gears to enhance their durability and strength. The process involves heating the steel to a high temperature and then rapidly cooling it to create a hard outer layer, known as the case, while maintaining a relatively softer core. This hardened surface provides resistance to wear, abrasion, and fatigue, allowing the gears to withstand heavy loads and prolonged use. Additionally, case-hardening steel also improves the gear's ability to withstand impact and retain its shape, ensuring efficient and reliable performance in various mechanical applications.

- Q: How is special steel used in the marine manufacturing process?

- Special steel is used in the marine manufacturing process for various applications, such as constructing ship hulls, propeller shafts, and offshore platforms. Its high strength, corrosion resistance, and ability to withstand harsh marine environments make it an ideal material choice. Additionally, special steel's excellent weldability and machinability ensure efficient and reliable production in the marine industry.

- Q: How does special steel compare to other high-performance materials?

- Special steel is known for its exceptional strength, durability, and versatility, which sets it apart from other high-performance materials. Compared to materials like aluminum, titanium, and composites, special steel often exhibits higher tensile strength, making it suitable for applications that require robustness and load-bearing capabilities. Additionally, special steel has excellent resistance to corrosion, heat, and wear, making it ideal for use in harsh environments or high-temperature applications. One advantage of special steel over other high-performance materials is its cost-effectiveness. Compared to materials like titanium, special steel is more affordable, making it a preferred choice for various industries. Moreover, the manufacturing process of special steel allows for customization, enabling the production of a wide range of grades and compositions to suit specific requirements. Special steel also offers excellent machinability and weldability, allowing for easy fabrication and assembly. Its versatility enables it to be used in a wide range of industries, including automotive, aerospace, construction, and energy. From structural components to precision tools, special steel provides a reliable and efficient solution. However, it is important to note that the choice of material depends on the specific application and its requirements. While special steel has numerous advantages, other high-performance materials may be more suitable for certain applications, such as lightweight components or extreme temperature conditions. Therefore, a comprehensive evaluation of the specific needs and characteristics of the application is necessary before determining the most appropriate material.

Send your message to us

CGCC PPGI Coils from CJC Steel Factory Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords