PPGI Coils from Tianjin Steel Material Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PPGI Coils from Shandong

Description of PPGI Coils from Shandong

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of PPGI Coils from Shandong

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

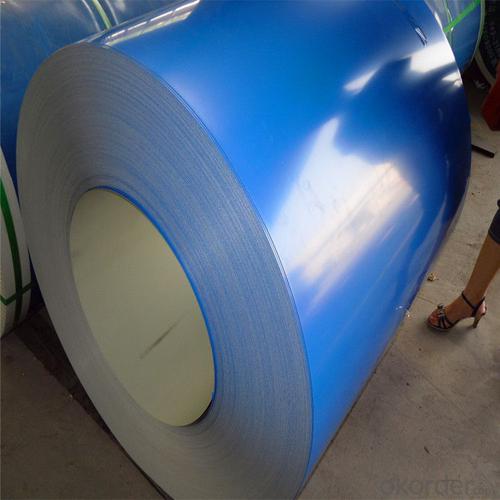

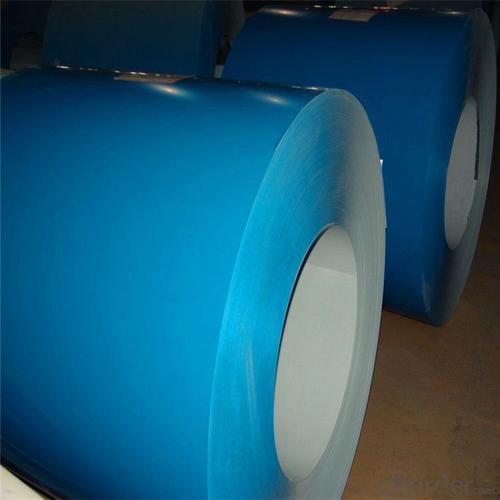

Products Show of PPGI Coils from Shandong

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How is nitriding steel used in the production of tools and dies?

- Nitriding steel is used in the production of tools and dies through a process called nitriding. This involves introducing nitrogen into the surface of the steel, which forms a hard layer of nitrides, increasing the overall hardness, wear resistance, and corrosion resistance of the material. This enhanced surface hardness makes the tools and dies more durable and long-lasting, allowing them to withstand the high stresses and temperatures experienced during cutting, forming, and shaping processes. Additionally, nitriding steel can also improve the fatigue strength and reduce the friction of the tools and dies, enhancing their performance and efficiency in various industrial applications.

- Q: What are the different high-temperature grades of special steel?

- There are several different high-temperature grades of special steel that are designed to withstand extreme heat and provide enhanced mechanical properties. Some of the most commonly used high-temperature grades include: 1. Stainless steel 310: This grade is known for its excellent resistance to oxidation at high temperatures. It has a high chromium and nickel content, which provides good corrosion resistance and high strength at elevated temperatures. 2. Inconel 625: Inconel alloys are nickel-based superalloys that are highly resistant to oxidation and corrosion. Inconel 625, in particular, offers excellent strength and toughness at high temperatures, making it suitable for applications in the aerospace and chemical processing industries. 3. Hastelloy X: Hastelloy X is a nickel-chromium-iron-molybdenum alloy that exhibits exceptional strength and oxidation resistance at high temperatures. It is commonly used in gas turbine engines, industrial furnace components, and other high-temperature applications. 4. Alloy 800H: This grade of special steel is an austenitic alloy with high resistance to oxidation, carburization, and nitridation. It is often used in heat exchangers, furnace components, and petrochemical applications. 5. Titanium Grade 5: Although not technically a steel, titanium grade 5 is a high-temperature alloy that offers outstanding strength and corrosion resistance at elevated temperatures. It is commonly used in aircraft engine components, chemical processing equipment, and marine applications. These are just a few examples of the high-temperature grades of special steel available in the market. Each grade is specifically designed to excel in different applications where extreme heat resistance and mechanical properties are required.

- Q: What are the main advantages of using special steel in the construction industry?

- The main advantages of using special steel in the construction industry are its high strength, durability, and resistance to corrosion. Special steel has superior mechanical properties compared to regular steel, allowing for the construction of stronger and more robust structures. It can withstand heavy loads, extreme weather conditions, and natural disasters, ensuring the safety and longevity of buildings. Additionally, its corrosion resistance properties reduce maintenance costs and extend the lifespan of structures, making it a cost-effective choice in the long run.

- Q: Can special steel be used in the construction equipment manufacturing industry?

- Yes, special steel can be used in the construction equipment manufacturing industry. Special steel is known for its exceptional strength, durability, and resistance to wear and tear, making it suitable for constructing heavy-duty machinery and equipment used in the construction industry. It offers superior performance in challenging and demanding applications, ensuring the longevity and reliability of the manufactured equipment. Additionally, special steel can be tailored to meet specific requirements and improve the functionality and efficiency of construction equipment.

- Q: What are the different methods of heat treatment for special steel?

- Special steel can undergo various heat treatment methods, each designed to enhance specific properties. These methods are as follows: 1. Annealing: By heating the steel to a specific temperature and gradually cooling it, typically in a controlled atmosphere, annealing helps relieve internal stresses, improve machinability, and soften the steel for further processing. 2. Normalizing: This process involves heating the steel above its critical temperature and then air cooling it in still air. Normalizing refines the grain structure, improves mechanical properties, and enhances strength and toughness. 3. Quenching: By rapidly cooling the steel from a high temperature using quenching mediums like oil, water, or brine, quenching creates a hard and brittle structure called martensite. This increases the steel's hardness and wear resistance. 4. Tempering: After quenching, the steel is reheated to a specific temperature and held there for a certain period, followed by air cooling. Tempering reduces the brittleness caused by quenching, improving toughness, ductility, and impact resistance. 5. Austempering: This method involves quenching the steel from a high temperature and then holding it at a specific temperature for an extended period. Austempering produces a structure called bainite, which offers a combination of strength, toughness, and ductility. 6. Martempering: A variation of quenching, martempering involves cooling the steel just above its martensitic transformation range and holding it at that temperature until uniformly cooled. This method reduces the risk of distortion and cracking, providing improved toughness and dimensional stability. 7. Induction hardening: Specifically used to selectively harden certain areas of the steel's surface, induction hardening involves heating the surface using induction heating and rapidly quenching it. This process creates a hardened surface layer while maintaining core toughness and ductility. These diverse heat treatment methods for special steel offer a range of options to optimize desired properties depending on specific applications and requirements.

- Q: What are the specific requirements for special steel used in the defense sector?

- Due to the critical nature of its applications, the defense sector imposes highly demanding requirements on special steel. These requirements encompass: 1. Exceptional strength and durability: Special steel utilized in the defense sector must possess outstanding strength and durability to withstand extreme conditions and endure wear and tear. It should have the capacity to endure high levels of stress, impact, and pressure. 2. Superior corrosion resistance: Defense equipment frequently operates in harsh environments and is exposed to elements that can cause corrosion. Consequently, special steel employed in the defense sector must display excellent corrosion resistance properties to ensure the equipment's longevity and reliability. 3. Heat resistance: Defense applications often involve exposure to high temperatures, such as in jet engines or armored vehicle components. Special steel used in these sectors must retain its strength and structural integrity even at elevated temperatures. 4. Machinability and weldability: Special steel employed in the defense sector should possess favorable machinability and weldability characteristics to facilitate manufacturing and assembly processes. This allows for ease of fabrication, repair, and maintenance of defense equipment. 5. Hardness and toughness: Defense applications necessitate a combination of hardness and toughness in special steel. It must resist penetration and deformation while simultaneously being able to absorb energy and resist fracture. 6. Non-magnetic properties: In specific defense applications, such as submarines and magnetic resonance imaging (MRI) equipment, non-magnetic properties are essential. Special steel employed in these sectors must possess low magnetic permeability to prevent interference with sensitive electronic systems. 7. Certification and compliance: Special steel used in the defense sector must meet specific certification and compliance standards, such as those established by defense organizations or international quality management systems like ISO 9001. These standards guarantee the quality, traceability, and reliability of the steel. Meeting these specific requirements for special steel utilized in the defense sector is crucial to ensure the safety, effectiveness, and longevity of defense equipment and systems. Rigorous testing and quality control processes are implemented to ensure that the steel meets the required specifications and standards.

- Q: What industries use special steel?

- Special steel plays a vital role in multiple industries, relying on its unique properties to carry out their operations. The automotive industry, for instance, utilizes special steel extensively in manufacturing engine parts, transmission systems, and chassis components. The exceptional strength, durability, and corrosion resistance of special steel make it an ideal choice for withstanding the challenging conditions faced by automotive components. Similarly, the aerospace industry heavily relies on special steel in constructing aircraft structures, engine components, and landing gear systems. The lightweight yet robust characteristics of special steel are crucial in ensuring the safety and performance of aircraft. In the energy sector, special steel is essential for producing equipment used in oil and gas exploration, such as drilling rigs, pipelines, and offshore platforms. The high-strength and corrosion-resistant properties of special steel enable it to withstand the harsh operating conditions prevalent in this industry. The construction industry is also a significant consumer of special steel, using it in the manufacturing of structural components, reinforcing bars, and precast concrete products. Special steel provides the necessary strength and durability required for building structures capable of withstanding diverse environmental conditions and heavy loads. Moreover, the manufacturing and machinery industry relies on special steel for producing heavy machinery, industrial equipment, and machine tools. The exceptional strength, wear resistance, and heat resistance properties of special steel make it well-suited to meet the demanding requirements of these applications. Lastly, the defense and military industry heavily depends on special steel for producing military vehicles, weapons, and armor. Special steel's ability to withstand extreme conditions and provide protection makes it a critical material in this industry. Overall, special steel's exceptional properties of strength, durability, corrosion resistance, and heat resistance make it indispensable across various industries. Its applications span from automotive and aerospace to energy, construction, manufacturing, and defense sectors, where reliability and performance are of paramount importance.

- Q: What are the limitations of welding special steel?

- There are several limitations associated with welding special steel. Firstly, special steels often have high carbon content or alloying elements, which can lead to increased susceptibility to cracking during the welding process. Additionally, special steels may have unique microstructures, such as high hardness or brittleness, which can pose challenges in achieving proper weld penetration and joint strength. Furthermore, the heat input required for welding special steels can result in distortion or warping of the workpiece, requiring additional post-welding processes to correct. Finally, special steels may require specific pre-welding preparations, such as preheating or special welding consumables, which can increase the complexity and cost of the welding process.

- Q: How does special steel perform in high-frequency applications?

- Special steel, also known as high-speed steel (HSS), performs exceptionally well in high-frequency applications. This type of steel is specifically designed to withstand the extreme heat and stress generated in high-speed machining operations. The unique composition of special steel, which typically includes elements such as tungsten, molybdenum, cobalt, and vanadium, provides it with remarkable hardness, toughness, and wear resistance. These properties make it highly suitable for use in high-frequency applications where the material is subjected to rapid cutting speeds and frequent abrasion. Due to its excellent hardness, special steel can maintain its cutting edge even at elevated temperatures, ensuring superior performance in high-frequency applications. It exhibits minimal deformation or loss of cutting efficiency, which results in improved productivity and extended tool life. Moreover, its exceptional wear resistance allows it to withstand the constant friction and heat generated during high-speed machining operations, preventing premature tool failure. Furthermore, special steel possesses excellent thermal conductivity, which helps dissipate the heat generated during high-frequency applications. This feature is crucial for maintaining dimensional stability and preventing the material from warping or distorting under extreme temperatures. As a result, special steel tools can maintain their precision and accuracy even during prolonged high-frequency operations. In summary, special steel is highly effective in high-frequency applications due to its exceptional hardness, toughness, wear resistance, and thermal conductivity. Its ability to withstand extreme heat and stress, while maintaining cutting performance and dimensional stability, makes it the preferred choice for industries such as aerospace, automotive, and manufacturing where high-speed machining is essential.

- Q: Can special steel be used in the manufacturing of sports equipment?

- Yes, special steel can be used in the manufacturing of sports equipment. Special steel, such as carbon steel or stainless steel, provides durability, strength, and corrosion resistance, making it suitable for various sports equipment like golf clubs, tennis racquets, or bicycle frames.

Send your message to us

PPGI Coils from Tianjin Steel Material Mills

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords