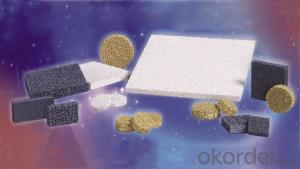

High Porosity Ceramic Filter Plate Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter has the advantages of high porosity, good thermal shock resistance,high mechanical strength, large specific surface and stable chemical property. In addition, with the excellent function of filtering, residuum collection and absorption, it can remove the impurities of 1-10μm efficiently. The outstanding three dimensional structure can reduce the turbulence and extrude the air in mould filling, provide consistent and rapid metal flow, improve the casting quality prominently.Ceramic Foam Filter can also be applied in gas treatment at high temperature, carrier of catalyzer, solid thermal exchange and special filling for chemical industry.

With more than ten years of research and development, enriches its product scope with different series of foam filters such as Alumina, Silicon Carbide and Zirconia.

Alumina foam filter (JG-1): For molten metal filtering under the temperature of 1200℃;

Silicon Carbide foam filter (JG-201, JG-202): For molten metal filtering under the temperature of 1550℃

Zirconia foam filter (JG-3): For molten metal filtering under temperature of 1700℃.

APPLICATION OF CERAMIC FOAM FILTER

Selection of ceramic foam filter

1) Selection of pore size is based on the weight and material of casting, regularly 10ppi for Stainless Steel; 10ppi for Ductile Iron; 20ppi for Grey Iron; 15ppi, 20ppi and 30ppi for non-ferrous alloy castings:

2) Foam filter size is decided by the sculpt, fusion and the characteristic of the ceramic foam filters.

3)'Ceramic foam filters should be fixed in the runner and ensure its uniform pressure.

4) Strictly control the pouring pressure and reduce the impact of hot molten metal.

5) Ceramic foam filters under ultra-high temperature are prohibited.

6) Strictly avoid using the ceramic foam filters to control the flow speed of molten metals

Attentions for store and application

Ceramic foam filters should be stored in dry environment to avoid moisture. Ceramic foam filters are fragile materials, rough handling in transportation is prohibited. It is recommended to blow the scum with compressed air before using

The advantage of application ofceramic foam filter

1) Reduce the defective rate and improve the casting yield.

2) Reduce the machining allowances and improve machinability of casting.

3) Improve the mechanical property of casting

4) Simplify pouring systems and improve the utilization ratio of mould

TYPICAL INSTALLATION OF CERAMIC FOAM FILTERS

Based on the characteristic of casting and the filters' working condition, ceramic foam filters can be fixed in different parts of the pouring system

1、Installation in the pouring cup: Commonly for precision casting and the casting of iron model covers the granulated substance

2、Horizontal installation in vertical runner: For small part with few pouring molten iron, especially for casting system with a vertical runner located at mould center and multiple branches of horizontal runner

3、Horizontally installation in horizontal runner: It makes molten metal casting stable, avoiding directly impacting the filter. This will increase slag blocking ability and make installation convenient.

4、Vertically installation in horizontal runner: To increase molten metal flow speed and enhance the filling capacity. Since molten metal directly impacts the fillers, the impact resistance of filters should be considered

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: What are the causes of the powder moisture in the ceramic filter?

- The ore condition has changed, such as high concentration of material, fine grain size and increase of mud content.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: Can the plate filter press pass through the filter plate?

- Specific, it is necessary to choose the filter characteristics according to different materials. Plate and frame filter press: plate and frame filter press is an industrial realization of solid, liquid separation, plate and frame filter press is suspension, liquid-solid, liquid two phase, applied to chemical, ceramics, oil

- Q: The use of water glass as beneficiation agent, copper concentrate in the ceramic filter can not filter, how to do?

- As everyone knows, ceramic filter medium is a ceramic filter plate, microporous ceramic filter plate with a lot of distribution from the outside to the inside capillary effect, its mechanism is based on the capillary effect of microporous ceramic filter, filtration, the filtrate (generally refers to water) through these pores under the action of the vacuum suction pump, filter cake is trapped on the surface of the ceramic filter plate.

- Q: The vacuum degree of the ceramic filter is normal and the cake water is large

- There is a difference between the vacuum display and the actual vacuumThe main speed of the ceramic filter is too fastThe water content of the filter cake is gradually increased within 0~8 hours after the equipment has been continuously turned onThe ceramic filter plate does not meet the aperture range and the opening rate is lowThe ceramic filter plate has a near life and serious blockageCeramic filter cleaning standards (acid, ultrasonic, backwash water)The scraper can not be completely discharged, and the surface of the ceramic plate is coated with a thin filter cakeFailure to manufacture equipment or other causes of failure

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: What is the reason that the ceramic filter does not absorb mineral powder?

- The recoil pressure is regulated by the pump loop valve and the pressure regulating valve. In order to avoid frequent fluctuations in pressure and pressure within a short period of time, a buffer cylinder with a stabilizing effect is provided in the backwash pipe.

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- When the ceramic filter works, the operation may be as follows: 1. The feed is injected and the pulp is injected into the tank of the ceramic filter. 2, mixing system, ceramic filter stirring rake back and forth mixing, driven by mixing reducer. 3, spindle rotation, material level reached a certain range, through the spindle speed machine to drive the ceramic filter disk rotation.

Send your message to us

High Porosity Ceramic Filter Plate Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords