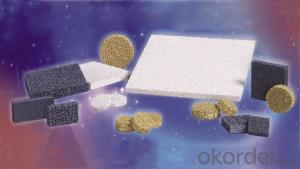

High Porosity Alumina Ceramic Filter Plate Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic Foam Filter has the advantages of high porosity, good thermal shock resistance,high mechanical strength, large specific surface and stable chemical property. In addition, with the excellent function of filtering, residuum collection and absorption, it can remove the impurities of 1-10μm efficiently. The outstanding three dimensional structure can reduce the turbulence and extrude the air in mould filling, provide consistent and rapid metal flow, improve the casting quality prominently.Ceramic Foam Filter can also be applied in gas treatment at high temperature, carrier of catalyzer, solid thermal exchange and special filling for chemical industry.

With more than ten years of research and development, enriches its product scope with different series of foam filters such as Alumina, Silicon Carbide and Zirconia.

Alumina foam filter (JG-1): For molten metal filtering under the temperature of 1200℃;

Silicon Carbide foam filter (JG-201, JG-202): For molten metal filtering under the temperature of 1550℃

Zirconia foam filter (JG-3): For molten metal filtering under temperature of 1700℃.

APPLICATION OF CERAMIC FOAM FILTER

Selection of ceramic foam filter

1) Selection of pore size is based on the weight and material of casting, regularly 10ppi for Stainless Steel; 10ppi for Ductile Iron; 20ppi for Grey Iron; 15ppi, 20ppi and 30ppi for non-ferrous alloy castings:

2) Foam filter size is decided by the sculpt, fusion and the characteristic of the ceramic foam filters.

3)'Ceramic foam filters should be fixed in the runner and ensure its uniform pressure.

4) Strictly control the pouring pressure and reduce the impact of hot molten metal.

5) Ceramic foam filters under ultra-high temperature are prohibited.

6) Strictly avoid using the ceramic foam filters to control the flow speed of molten metals

Attentions for store and application

Ceramic foam filters should be stored in dry environment to avoid moisture. Ceramic foam filters are fragile materials, rough handling in transportation is prohibited. It is recommended to blow the scum with compressed air before using

The advantage of application ofceramic foam filter

1) Reduce the defective rate and improve the casting yield.

2) Reduce the machining allowances and improve machinability of casting.

3) Improve the mechanical property of casting

4) Simplify pouring systems and improve the utilization ratio of mould

TYPICAL INSTALLATION OF CERAMIC FOAM FILTERS

Based on the characteristic of casting and the filters' working condition, ceramic foam filters can be fixed in different parts of the pouring system

1、Installation in the pouring cup: Commonly for precision casting and the casting of iron model covers the granulated substance

2、Horizontal installation in vertical runner: For small part with few pouring molten iron, especially for casting system with a vertical runner located at mould center and multiple branches of horizontal runner

3、Horizontally installation in horizontal runner: It makes molten metal casting stable, avoiding directly impacting the filter. This will increase slag blocking ability and make installation convenient.

4、Vertically installation in horizontal runner: To increase molten metal flow speed and enhance the filling capacity. Since molten metal directly impacts the fillers, the impact resistance of filters should be considered

- Q: Performance advantages of ceramic filter

- A ceramic filter for fine coal mud recovery, there is a base, the lower part of the frame is provided with a fine slime liquid trough, the fine slime liquid material groove is provided with a liquid level controller, the slime liquid material at both ends of the groove is provided with a negative pressure water tank, the water tank is provided with a negative pressure suction connection assembly fixing the other side is provided with a vacuum pump pipeline, the pipeline is communicated with a vacuum pump and vacuum pump;

- Q: What are the poor filtration effects of vacuum disc filters?

- The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed.

- Q: What happens when the pressure on the filter plate is uneven during backwashing?

- It should be said that the ceramic filter backwash, usually with a certain pressure of clean water to backwash.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The filtrate is not discharged smoothly.The filtrate can not be discharged in a timely and smooth manner, the new filtrate can not be sucked out, and the filtrate can not be continuously sucked out, so that the filter cake can not be adsorbed on the ceramic plate.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- It should be noted that due to wear, plugging and so on, the new and different degrees of ceramic film, the pore size will change. Micron scale ceramic membrane filtration accuracy is very good, nano scale aperture range of such a small ceramic film does not know in what way.

- Q: How much is the accuracy of 50nm ceramic membrane filtration?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Equipment comes with cleaning:Ceramic filter comes with a combined cleaning system, usually to ensure the normal backwash water pressure, combined cleaning (nitric acid + ultrasonic + backwash) time is sufficient, sufficient amount of nitric acid.

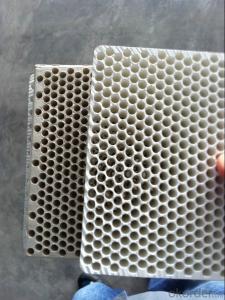

- Q: What are the functions of honeycomb ceramic filters?

- At present, it is widely used in metallurgy, foundry industry, metal melt filtration, using mullite (cordierite) ceramic materials

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber board quality can be judged from the following aspects:1, appearance. The surface is flat and the cutting surface is well arranged, and vice versa.2 density. Press the hands, and the surface is soft and smooth.3, process. Vacuum suction and continuous production process.4, cross section, slag ball content is low.

Send your message to us

High Porosity Alumina Ceramic Filter Plate Series

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords