calcium silicate board --- Concrete Polystyrene Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

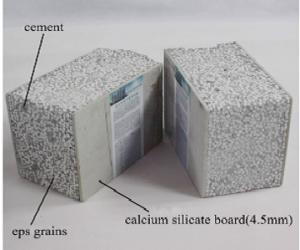

Composition: EPS+cement+calcium silicate board

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

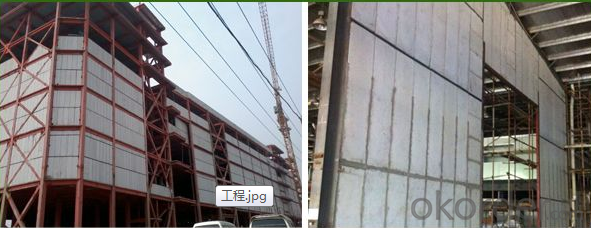

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Project

Certificate

Q1: How soon can we receive the goods after purchase? A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q2: How to make a quick resolution for after service? A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: What is the current project wall, which kind of roof? There are commonly used models

- Sandwich board consists of three parts: the upper and lower two forming steel plate, the middle of the core board (with rock wool, polystyrene, polyurethane) thickness of 50mm / 75mm / 100mm, both sides of the strip. Mainly used for the activities of the wall panels and roof panels, and a variety of large factories. The color pressure plate is an integral part of the sandwich panel, that is, the upper and lower forming plates. Generally used for site Wai block, warehouse panel. The model wall is made of 950 rock wool wall sandwich panel composite board, roof 960 rock wool roof sandwich panel

- Q: Rock wool color steel sandwich panels how to choose

- Selection: Caigang rock wool sandwich board sub-machine board and manual plate two, Caigang sandwich panel is made of two layers of color coated steel plate for the surface layer, through the automatic compound molding machine, in the steel plate coated glue , At the same time on both sides of the board embedded in thin-walled channel, the pressure, blanking from the plate. 1, the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × 50, L × 1150 × 75, L × 1150 × 100 2, handmade rock wool color steel sandwich panel specifications: L × 985 × 50 3, color steel rock wool sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. 4, rock wool density: ≥ 120kg / m3 5, thermal conductivity: ≤ 0.046w / m.k 6, combustion performance: A-level (non-combustible) Caigang rock wool sandwich board for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding appropriate amount of binder, curing and made of processing. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on.

- Q: I just got a polyurethane sandwich board production line, I would like to ask about making money!

- Soft surface or color steel? Color steel is now OK, soft surface of many areas do not let the country, B2 is not up to standard, B1 technology is not mature, and now do the wall decoration board quite fire

- Q: New rock wool sandwich board polyurethane edge how much money one meter

- Do not do the fire to investigate or deal with either Yanmian board or polyurethane board price is the polyurethane invoice does not send about 130% of the price of rock wool

- Q: Introduction of foam sandwich panels

- Foam sandwich panels beautiful appearance, bright color, the overall effect is good, it sets load, insulation, waterproof in one, and no secondary decoration, is a wide range of uses, especially in the construction site for temporary facilities such as office, Wall, etc., but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be installed in the removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Will be indispensable for new lightweight building materials.

- Q: OKorder where to sell rock wool color plate, rock wool sandwich panels and good quality?

- OKorder multi-dimensional joint light steel sheet of the good, mostly for the project.

- Q: What are the key notes when buying a rock wool sandwich panel?

- 1. Slag content; slag content determines the quality of rock wool. High-quality rock wool is made from basalt or diabase, while poor quality rock wool is mixed with blast furnace slag or other metallurgical slag. In contrast, the slag content is low and the acidity is low Poor, with the temperature changes will greatly accelerate the fiber fracture and powder, thus losing strength and insulation properties. So, will become a building hazard. 2. Fiber average diameter; national standard is ≤ 7μm. The new rock wool fiber-forming process combined with the basalt material itself makes the rock wool fiber slender and flexible, the fiber diameter can be stabilized at 4-7μm; the pendulum method and the multi-dimensional pleating technique make the distribution of the Yanmian fiber evenly and in three dimensions Chaos, greatly improving the density and strength of rock wool. 3. Thermal conductivity; high quality rockwool slag ball content is low, fiber diameter is moderate, the use of pendulum method of production technology, fiber distribution, uniform direction, bulk density uniformity, low thermal conductivity. Poor rock wool is the opposite. Usually slag cotton using sedimentation chamber production process, low thermal conductivity

- Q: Is the sandwich panel a mezzanine? What is the effect of painting? How long can I use life on the cabinet? Best example! My house in the decoration What is the cost of a sheet plus paint? Will the board be put on the floor after painting and painting?

- Sandwich panels do not refer to blockboards, because the sandwich panels are many kinds, including three PCT board, five PCT board, nine PCT board ... ... can only say that the blockboard is a kind of sandwich panels. Not directly in the blockboard on the paint, usually on the outside to paste decorative panels, and then clear oil process, if you want to paint directly on the plate, please use medium density board, used for making furniture, oil mixing process! Maintenance is good, life is not a problem! But can buy as much as possible to buy, do not live production. After all, the scene can not reach the factory clean paint, and did not sell the beautiful. ???? The general plate is not very expensive, but do not underestimate the paint! Will the board be put on the floor after painting and painting? The answer is yes, the plate had to nail a layer of gypsum board, and then putty putty paint, so that will not be delaminated.

- Q: What is the polyurethane sandwich board material

- Double-sided color steel, the middle of the polyurethane sandwich composite panels Generally used in the roof of the building roof, the board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety. Upper and lower board plus the common role of polyurethane, with high strength and stiffness, the lower plate smooth and smooth, clear lines, increase indoor aesthetics, flatness. Easy installation, short duration, beautiful, is a new type of building materials.

- Q: Color steel tile foam sandwich board model is how the classification

- Common sandwich panels: foam sandwich panels, rock wool sandwich panels, polyurethane sandwich panels. Common specifications: roof board 980, wall board 950. Common thickness: 50mm, 75mm, 100m.

Send your message to us

calcium silicate board --- Concrete Polystyrene Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords