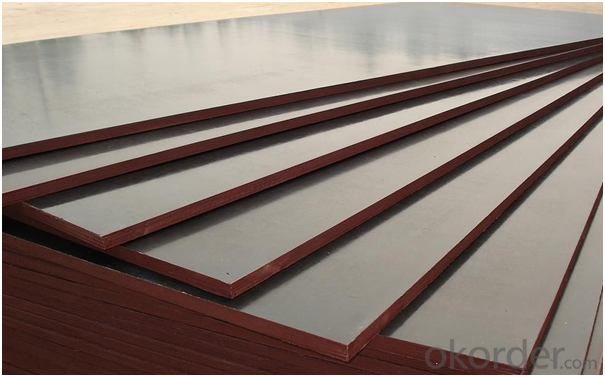

Film faced plywood 18mm thickness for construction application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

construction application of Film faced plywood 18mm thickness

Product Details:

Hardwood, Birch

· Standard Size: 1220x2440mm,1250x2500mm

· Glue: Melamine WBP, Phenolic WBP,MR

· Film: Brown, Red, Black

· Cycle Life: about 6~10 repeated using times

Packaging & Delivery

Product Description:

Film faced plywood is mainly made up of eucalyptus plywood, poplar plywood or eucalyptus and poplar plywood, it is economic and practical for the construction concrete pouring, for it could be the face panel for any formwork system, for example, steel frame formwork system, single side formwork system, timber beam formwork system, steel props formwork system, scaffolding formwork system, etc.

Product features:

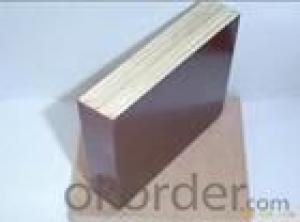

1. Light Weight: We choose the high grade eucalyptus and poplar as the basic material, they are very light, so film faced plywood is convenient for transporting, and only one person could delivery single formwork by hand.

2. Easy To Cut: the plywood is easy to cut, so according to the construction, the formwork could be cut into the required size.

3. Re-used: Film faced plywood could be used 8-10 times.

4. Multi Using: Film faced plywood could be used for wall, slab, column, beam and bridge concrete pouring etc.

5. No Deformation: Film faced plywood is also whole but not deformation and chipping after 72 hours cooking in boiling water.

6. High Quality Film: It protect the formwork surface from the corrosion and makes the formwork durable, improves the flatness of the concrete surface and makes the concrete surface save the second time plastering, so it could save a lot cost of construction.

Product Specification:

Product Name | Film faced plywood | ||||

F/B | Black film, brown film, red film | ||||

Grade | Construction grade(one/two time hot press) | ||||

Core | Poplar, hardwood, birch, pine, combi , and so on | ||||

Glue | melamine and WBP | ||||

Thickness | 9-25mm | ||||

Specification | 1220x2440mm, 1250x2500mm,915x1830mm | ||||

Moisture Content | 8-10% | ||||

Package | Standard export packing | ||||

Press | one times press/two time press grade | ||||

MOQ | 1x20GP | ||||

Price Terms | FOB, CIF, CFR | ||||

Payment | T/T 30%, irrevocable LC | ||||

Delivery Time | Within 15 days after order confirmed | ||||

Supply Capacity | 4500 cbm/month | ||||

Usages | Can be widely used for building concrete, etc | ||||

Remarks | Top class equipment with top class produce technique; Credit first, fair trading | ||||

Formaldehyde Emission Standards | E2<30mg/100kg E1<9mg/100kg E0<5mg/100kg | ||||

Thickness(mm) | Layers | Standard size | Large size | ||

min. (mm) | max.(mm) | min.(mm) | max.(mm) | ||

9 | 7 | 8.5 | 9.5 | 8.2 | 9.5 |

12 | 8 | 11.5 | 12.5 | 11.2 | 12.5 |

15 | 9-10 | 14.5 | 15.5 | 14.2 | 15.5 |

18 | 11 | 17.5 | 18.5 | 17.2 | 18.5 |

21 | 13 | 20.2 | 21.5 | 20.2 | 21.5 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Sandwich board glue where the good

- There are too many types of glue can not be unified If it is on the market of ordinary glue, its composition is basically water, add some polyvinyl alcohol, white latex, sodium stearate, talc, urea, ethylene glycol, sucrose, flavor, etc., little harm to the human body (if Used to eat), if used when the eye drops with the estimated consequences are more serious. 502 glue is the main component of α-cyanoacrylate, its essence is colorless and transparent, low viscosity, non-combustible liquid, a single component, no solvent, slightly stimulating taste, volatile, volatile gas with weak tear The Building adhesive, 707 emulsion and other high-level additives, the current commonly used 108 plastic main component of polyvinyl alcohol Scope This product is suitable for concrete, aerated concrete, lime sand brick, fly ash brick interface treatment, can also be used for plastering mortar, paste the tile sand ash additives to enhance the adhesive force.

- Q: Housing ceiling with a good light or good sandwich panels

- Of course, light steel keel Well, first of all, wood keel easy to crack, deformation. Because the wood keel is not moisture, which easily lead to ceiling cracking, deformation, and easy to be corrosion, insects. In addition to the above problems, there are hidden dangers such as ceiling fall. Second, the wood keel strength and toughness is poor, resulting in the ceiling, partition wall life is short, and not fire, easily lead to fire. Light steel keel is a substitute for wood keel. Light steel keel with high strength, corrosion resistance, structural stability, easy to deformation and so on. Its flatness is better, the construction speed, good stability, as well as fire, moisture and other advantages, so, in order to renovate the dormant hidden, it is best to use light steel keel.

- Q: How to install the cold sandwich sandwich sandwich panels

- If the use of polyurethane cold storage board, then use the structure of the installation of the installation time can be reported to us can also install their own This is a drawing in accordance with the drawings can be installed

- Q: Fire rock wool color steel sandwich board 75 thick one square meter how much money?

- The price accounting for fire-resistant rock wool sandwich panels requires a number of factors, including the quality and brand of color steel sandwich panels, and whether rock wool needs hydrophobic rock wool and other factors. For specific price accounting please contact the business.

- Q: Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Is the same product! Just called different.

- Q: What is the acceptance criteria for rock wool sandwich panels?

- 1) upper and lower surface: the use of galvanized color steel plate, the thickness of 0.4-0.8mm. According to the specific requirements of customers, can also be used galvanized steel or galvanized steel plate. The steel plate is first molded by a molding machine and is compounded with the rock wool factory. ? 2) Yanmian core material: the use of density of 120kg / m yan rock block staggered laying, the fiber perpendicular to the sandwich plate on the upper and lower surfaces, and close contact to enrich the sandwich panel of the entire vertical and horizontal. The combination of rock wool and rock wool and the upper and lower steel plates through the high-strength foaming agent to form a whole, sophisticated production process to ensure that the high-density rockwool insulation and metal plate between the inner wall can produce poles Strong adhesion, so that the rock wool sandwich panel has a very good stiffness. ? Wujiang City Linxue purification Choi Board Co., Ltd. is the China Electronics Society Clean Technology Branch members. Commitment to various types of purification decoration, clean air-conditioning works, hydropower engineering facilities supporting the design, installation, commissioning through-train service.

- Q: Industrial building facades

- Even the United States outside the wall panels, search Dalian, the official website of the United States chemical building materials.

- Q: EPS sandwich panel metal panel thickness requirements

- Generally see the customer's request, the steel from 0.2-1.2MM have, the general 0.4 up and down the most

- Q: Color steel rock wool sandwich board 50mm per square meter how much money

- The price by region, quality and demand to go, Tianjin is rock wool board manufacturers more cities, a single rock wool board, then many can do 40 or so per square meter

- Q: Does anyone know the reason why the sandwich panel is bubbling and partially degumming during the pressing process?

- Italian Prith hydraulic press gives the solution: 1, control the moisture content of the board in the range of 8 to 12% 2, control the amount of coating in line with process requirements 3, buck the second stage of the speed should be slow, hot pressing temperature should be appropriate to reduce 4, check the resin quality 5, the appropriate extension of hot pressing time Italy Pride & OKorder Ding Di CNC Equipment Co., Ltd., we have sufficient technical sales and administrative staff in the world to provide you with even the most challenging press engineering application solution for our customers. Provide spare parts replacement and factory direct on-site service to ensure that your satisfaction, so that your production operations at a moment of profitability.

Send your message to us

Film faced plywood 18mm thickness for construction application

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords