calcium silicate board --- Indoor Wall Paneling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

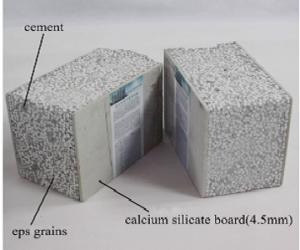

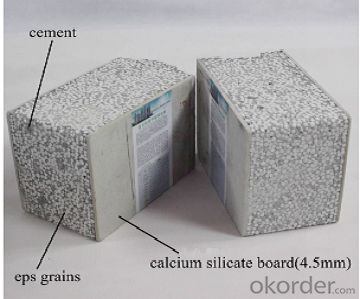

Composition: EPS+cement+calcium silicate board

Package (20GP)

Specification (mm) | Quantity (pcs) | Area (sqm) | Weight (kg) |

2270*610*60 | 306 | 424 | 19500 |

2270*610*75 | 252 | 349 | 18200 |

2270*610*90 | 207 | 287 | 17300 |

2270*610*100 | 189 | 262 | 17300 |

2270*610*120 | 153 | 212 | 15000 |

2270*610*150 | 126 | 175 | 13200 |

Usage

JY wall panel is widely used in the partition of highrise buildings, industrial plants, office buildings,

residential houses, work shed and other constructions. It can be also used as non load bearing structure of

washroom, kitchen and renovation of old houses. And it's particularly applicable to places with high fireresistance requirement.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (20-40 days after receiving deposit)

Reliable performance

Easy and smooth operation

High safety.

· Professional Service

· Competitive pricing

Project

Q2: How to make a quick resolution for after service?

A2: OKorder and our manufacture both have overseas branches all-around of world, If needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Certificate

Q3: How do we guarantee the quality?

A3: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q1: How soon can we receive the goods after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: And where are you? Will there be any differences in prices? I am Yuyao, Zhejiang

- Generally lower than the board are thinner than 0.5, the general difference to do 0.476. The basic price of 70 quick money, plus 3-5 and then

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q: How is the ceiling of the residential sandwich panel under the roof?

- Method is to use the form of flat ceiling, the top of the pipeline blocked in the ceiling, the top can be embedded in the downlight or built-in fluorescent lamp, so that the top of the decoration after the formation of two levels, will not produce a sense of depression. Shaped ceiling with a cloud-like wave or irregular arc, generally not more than one-third of the overall top area, more or less than this ratio, it is difficult to achieve good results.

- Q: Is the foam sandwich board one meter high?

- Some we do the highest of 21 meters

- Q: Does the color steel sandwich panel plant require an environmental permit?

- (1) a copy of the application form for environmental management of the construction project; (2) the registration form of the proposed environmental impact of the project; (3) the project proposal and the relevant department approval document of the project proposal; (4) Topographic map, the map should be marked around the proposed project; (5) the proposed project to be approved by the local Environmental Protection Agency.

- Q: Which color plate sandwich board price is low and good insulation

- The price is low polystyrene board, good insulation will use polyurethane

- Q: How to use the sandwich board to the concrete square column into a cylindrical and finishes are made of aluminum-plastic package, it is best to have pictures or drawings

- With a sandwich made of a semi-circular in the bottom of the column, the top and the middle of every 500 or so, with expansion bolts wooden side of the board will be fixed on the column, with a sandwich panel saw a narrow wood, Into a round wooden column of the pillars, and then stick to the aluminum plate.

- Q: What is the fire resistance time of the steel wool

- Fire detection report is half an hour

Send your message to us

calcium silicate board --- Indoor Wall Paneling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords