Specifications

1) ISO 9000 and SGS test report

2) Thickness:0.11-0.8mm

3) Width:400-1200mm

4) Payment term: T/T or L/C

5)Delivery : 3weeks

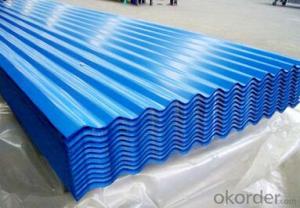

Galvanized corrugated sheet specification:

5) Surface treatment:

Thickness : 0.11 mm to 0.80 mm

Base coil width: 762mm, 914mm, 1000mm, 1200mm,1250mm

Length : from 2metre to 12metre long

Corrugated : 665 to 1000 mm

Length : 1600 to 4500 mm as required

Zinc Coating : 40 to 275 GSM as required

Spangle : minimized spangle; zero spangle; regular spangle; big spangle.Hardness: full hard

Surface treatment: Passivate (chromated); Oiled or unoil)

Packaging & Delivery

| package | Inner side: by water proofed kraft paper and plastic packing . Outside: covered by steel sheet and bundled the sheets on the steel pallet with steel strips. We can also meet others sea worthy export standard packing as customers' request.

|

| Delivery time | 3weeks after receiving the L/C or T/T deposit |

Product usage:

commercial use, structural use, household appliance, light industry, constructure

Our Export Markets:

We have been exporting our products to various countries including Africa, South Africa, Middle East, South American. (Tanzanian, Mozambique, Venezuela , Uruguay, Nicaragua,, Cambodia, Yemen, American