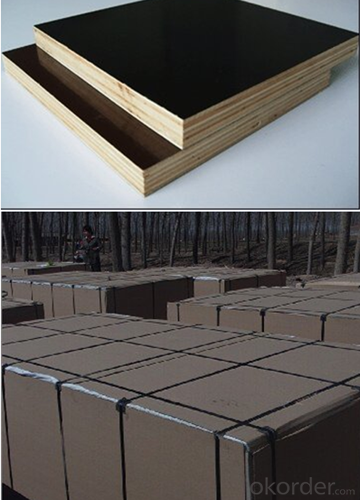

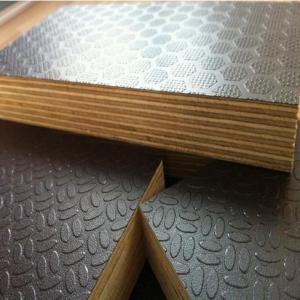

Anti Slip Brown Color Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Plywood Type: Veneer Boards

· Veneer Board Surface Finishing: Double-Sided Decoration

· Veneer Board Surface Material: poplar

· Size: 915*1830,1220*2440,1220*2550mm

· Glue: MR,WBP,MELAMINE

· Main market: Europe, The Middle East, Africa/Latin America

· Thickness: 9-35mm

· Certification: ISO9001

Packaging & Delivery:

Packaging Details: | Inner packing: inside pallet is covered with 0.2mm plastic bag; Outer packing: by pallet, wrapped in carton, reinforced with iron belt, and seaworthy for shipping by sea |

Delivery Detail: | within 15days after receiving prepay or against origin L/C |

Product Specifications:

Brown film faced plywood

Core: poplar and hardwood

Glue: WBP, melamine, MR

Film: Brown and black film

Size: 1220*2440mm

BROWN FILM FACED PLYWOOD

Product | brown film faced plywood |

Face and back | Okoume,bintangor,poplar,birch pine |

Core | Poplar,hardwood,birch or as your requests |

Thickness | 9-35mm |

Size | 1220*2440mm 1250x2500mm |

Glue | MR,WBP.MELAMINE |

color | black and brown |

Moisture | 6-14% |

Density | About 600kg/m3 |

Formaldehyde release | E0≤0.5mg/L E1≤1.5mg/L ≥E2≤5.0mg/L |

Bonding strength | ≥0.9mpa |

Packing | Inner with plastic bag, outside covered with |

Plywood at cartons, then steel tapes for strength | |

Transportation | 8plts/20GP,16plts/40GP,18plts/40HQ |

Payment | T/T, L/C |

Min order | one20GP |

Delivery time | within 15days after receiving prepay or against origin L/C |

Supply ability | 60*40HQ per month |

Certificate | ISO/CE |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Product Show:

- Q: Polyurethane sandwich panel production line which part of the composition, where the polyurethane sandwich panel production line is better?

- Polyurethane composite insulation board production line complete sets of equipment, mainly by the open system, film cutting system, forming machine system, steel preheating furnace, high pressure foaming system, double track system, double track heating system, cutting system, horizontal cooling system, palletizing Systems, packaging systems and a series of equipment. Zhongji Machinery Manufacturing Co., Ltd. was established in 1992, won the title of national high-tech enterprises, and the Ministry of Commerce was identified as designated equipment export manufacturers. But the price is more expensive!

- Q: Use the sandwich board to do the quotation of the wall how to do ah

- The board of the board is made of lightweight Polish special cement, EPS granule, expanded perlite, a variety of high-molecular light aggregate for core board, strong composite treatment made of lightweight partition plate

- Q: Is polystyrene sandwich board flammable?

- Conventional flat polystyrene polystyrene sandwich panels are non-flame retardant, there is a Hongxin source flame retardant polystyrene sandwich panels, but relatively less flame retardant effect such as rock wool and other core material sandwich panels , And now fire requirements are not allowed to use polystyrene sandwich panels

- Q: Can Caoyan rock wool sandwich panels be used as permanent construction timber?

- Can not, just take a simple color coated board for a long time will be corrosive

- Q: Which master asked me how to deal with the leakage of rain, worry about me

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the rainfall is large, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: Chongqing polyurethane sandwich panel manufacturers, Chongqing polyurethane sandwich board which is good

- 【Six performance】: 1, insulation energy: polyurethane core material closed porosity ≥ 96%, thermal conductivity ≤ 0.020, thermal insulation performance is superior. 2, fire retardant: the product through the authority of the national fire test, burning grade to GB8734-2008 relevant standards. 3, airtight watertight: good sound insulation, such as the impact of rain and water has a very weak effect; lap unique, strong water resistance. 4, environmental non-toxic: non-formaldehyde and other harmful substances, can be recycled re-use. 5, beautiful economy: plate effect of diverse, diverse colors; no secondary construction, saving construction time and costs. 6: construction convenience: polyurethane plate factory compound, constant temperature conditions, production, quality is very stable; construction fast, the application has been more than 40 years.

- Q: Sandwich board moldy how to deal with

- If the mold is generally difficult to clean out, you can use some alcohol class wipe, the mold to erase, it is best to go online to buy a small amount of Ai Hao Seoul fungicide spray up to ensure that the sandwich board is not Re-moldy.

- Q: Hard polyurethane sandwich board combustion performance?

- According to the industry standard JCT 868-2000 metal surface rigid polyurethane sandwich panels, sandwich panels combustion performance should reach B1 level. Classification of combustion performance grade in accordance with national standards GB 8624-1997.

- Q: Classification of color steel sandwich panels

- 1. There are six kinds of core materials: polystyrene sandwich panels that EPS sandwich panels (the market, the most widely used varieties); Extruded polystyrene sandwich panels that are XPS sandwich panels; Rigid polyurethane sandwich panels that PU sandwich panels; Trimer sandwich panel that is PIR sandwich panels; Phenolic sandwich panels that are PF sandwich panels; Rock wool sandwich panels are RW sandwich panels. 2. There are two types of panels: Metal panel and non-metal panel two. Metal panels are easy to process and can be made in a variety of shapes, but in some cases non-metallic panels have the effect of metal panels, such as corrosion resistance, impact resistance and so on. Widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities room, building plus layer, clean workshop and the need to heat insulation fire places. Sandwich board shape beautiful, bright color, the overall effect is good, it sets load, insulation, fire, waterproof in one, and no secondary decoration, quick and easy installation, short construction period, comprehensive benefits, is a wide range of uses, With the potential of efficient and environmentally friendly building materials.

- Q: Pressure steel plate sandwich panel roof and wall construction structure how to mine construction

- This involves a lot of standards, such as GB50057, can not enumerate, if there are such projects can find cooperation, see more time to see the standard to understand.

Send your message to us

Anti Slip Brown Color Film Faced Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m³

- Supply Capability:

- 9000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords