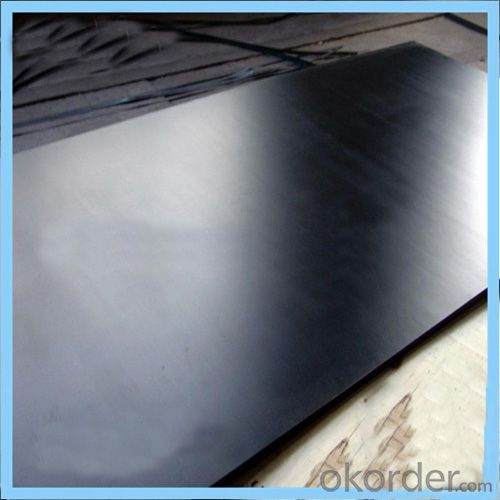

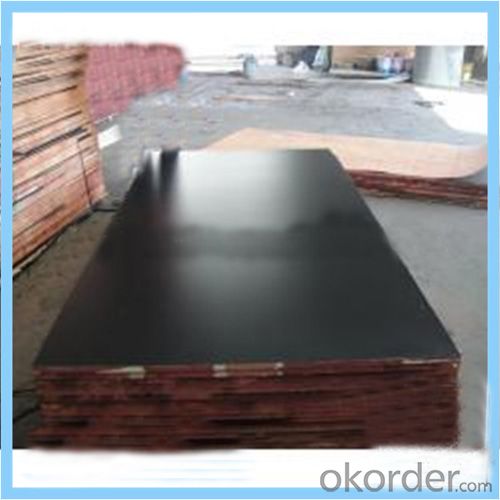

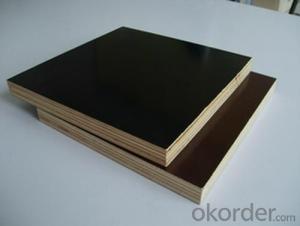

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

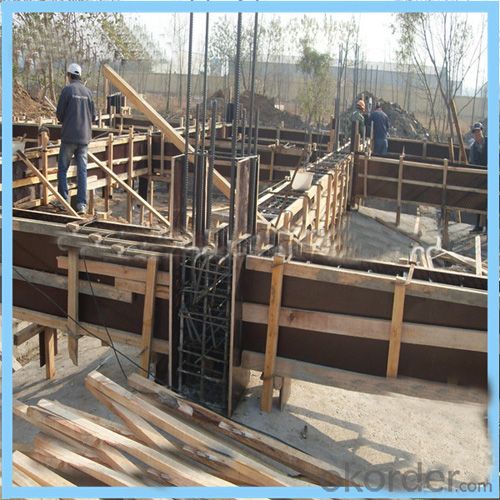

· Type: Plywoods

· Place of Origin: Shandong, China (Mainland)

· Brand Name: CHANTA

· Model Number: Film Faced Plywood L003

· Usage: Outdoor, Outdoor

· Grade: First-Class, First-Class

· Main Material: Poplar, Poplar

· Formaldehyde Emission Standards: E1

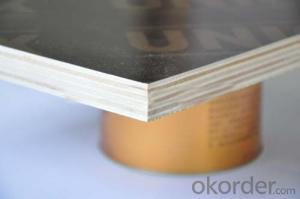

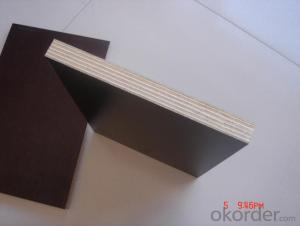

· Plywood Type: 13-Ply Boards, Film Faced Plywood

· Thickness: 9~20mm

· Moisture: about 12%

· Glue: WBP

· Certificate: CE, FSC, CARB, ISO9001:2000

· Film: Black/Brown

· Size: 1220x2440mm

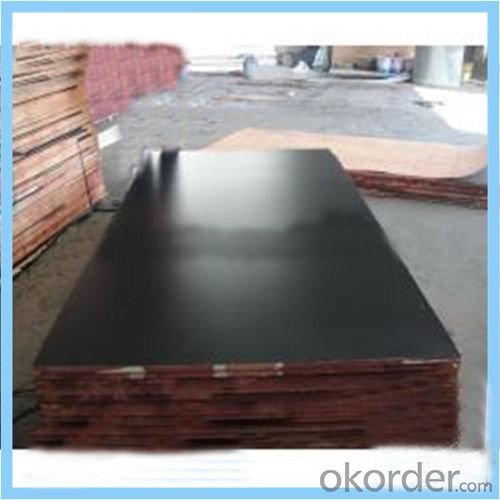

Packaging & Delivery:

Packaging Details: | Inter packing: 0.20mm plastic bag;Outer packing: pallets are covered with plywood or carton and then steel strips for strength |

Delivery Detail: | within 20 days upon the receipt of L/C or T/T |

Product Description:

FILM FACED PLYWOOD

size | 1220*2440mm/1250*2500mm |

thickness | 6mm,9mm,12mm,13.5mm,15mm,18mm,21mm |

core | poplar,birch,hardwood,combi or as your request |

film | black /brown ,Anti Sip film |

density | 500-700kgs/cbm |

moisture | less than 12% |

Thickenss tolerance | +/-0.5mm |

Modulus of rupture | ≥30Mpa |

Modulus of Elasticity | ≥ 6000MPa |

packing | bulk or standard pallet packing |

delivery time | within 15 days after received the deposit |

payment | 30% deposit TT, L/C at sight. |

Nepal Market Plywood 9mm 12mm Black Film Faced Plywood

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Blockboard (sandwich panel) decoration cabinet right?

- Now with the Malacca core blockboard, light and strong, flat without deformation, Malacca this wood is generally used to do musical instruments, you can not be good.

- Q: Use the sandwich board to do the quotation of the wall how to do ah

- The board of the board is made of lightweight Polish special cement, EPS granule, expanded perlite, a variety of high-molecular light aggregate for core board, strong composite treatment made of lightweight partition plate

- Q: Rock wool color steel sandwich panels how to choose

- Selection: Caigang rock wool sandwich board sub-machine board and manual plate two, Caigang sandwich panel is made of two layers of color coated steel plate for the surface layer, through the automatic compound molding machine, in the steel plate coated glue , At the same time on both sides of the board embedded in thin-walled channel, the pressure, blanking from the plate. 1, the mechanism of rock wool color steel sandwich panel specifications: L × 1150 × 50, L × 1150 × 75, L × 1150 × 100 2, handmade rock wool color steel sandwich panel specifications: L × 985 × 50 3, color steel rock wool sandwich panel thickness is divided into: 50mm, 75mm, 100mm, 150mm. 4, rock wool density: ≥ 120kg / m3 5, thermal conductivity: ≤ 0.046w / m.k 6, combustion performance: A-level (non-combustible) Caigang rock wool sandwich board for drying room, paint room, industrial equipment, construction, ship insulation, noise, etc., at the same time for electronic clean room, clean room, explosion-proof fire shop ceiling, partition and so on. Fire time is 70 minutes. Thickness 50-150mm rock wool insulation board is basalt and other natural ore as the main raw material, rock wool insulation board by high temperature melt fiber, adding appropriate amount of binder, curing and made of processing. Rock wool insulation board products for industrial equipment, construction, insulation, noise and so on.

- Q: The current market price is how much money a square meter?

- Polystyrene is a good point of its own do not have to consider the high temperature side of the polystyrene composite board cost-effective relatively high cost

- Q: Which master asked me how to deal with the leakage of rain, worry about me

- Color steel sandwich panels: 1. Corrugated sandwich board may be in the fixed when the nail is too tight lead to corrugated subsidence, the formation of small puddles, it will leak, the solution with mildew copper phosphate repair. 2. Flat sandwich plate may be due to the possibility of two plates of the gap between the edge of the gap is not enough height, the general rain is no problem, the rainfall is large, the solution is to increase the height of the edge fold (the cost of repair each gap about 15 yuan about). Also do not understand can ask!

- Q: Does the color steel sandwich panel plant require an environmental permit?

- (1) a copy of the application form for environmental management of the construction project; (2) the registration form of the proposed environmental impact of the project; (3) the project proposal and the relevant department approval document of the project proposal; (4) Topographic map, the map should be marked around the proposed project; (5) the proposed project to be approved by the local Environmental Protection Agency.

- Q: What kind of sandwich board is the phosphorous magnesium plate

- Magnesium board is a new type of multi-functional building materials. Using magnesium oxide, magnesium chloride as the main raw material, and a certain percentage of perlite, glass fiber mesh, wood fiber and other mixed processing. With light, fire, high strength, sound absorption, heat insulation, non-toxic harmless, corrosion-resistant, not mildew and so on. Can be used as a wall, ceiling ceiling, floor liner and so on.

- Q: I have a small shed, want to use sandwich panels construction, how can the summer 40 degrees with air conditioning to save power

- Wall plug a layer of sandwich panels no problem, but the window and sandwich panels to achieve the same insulation effect is difficult!

- Q: Color steel 50 mm rock wool sandwich board one meter how much the price

- I am a Schwab rock wool sales 5 cm 100K color steel plate rock wool sandwich panel is 22 a flat

Send your message to us

9mm & 12mm Black Film Faced Plywood for Nepal Market

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 53 m³

- Supply Capability:

- 8000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords