Calcined Petroleum Coke as Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 19.3

- Supply Capability:

- 1003 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.Good quality

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

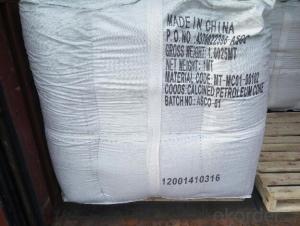

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: How does carbon form?speed

- How is coal formed?Coal is known as black gold, the food industry, it is one of the main energy use of the human world since eighteenth Century. Although its important position has been replaced by oil, but in the future for a long period of time, due to the exhaustion of petroleum, inevitable decline, but because of the huge reserves of coal, and the rapid development of science and technology, the new technology of coal gasification is becoming more mature and widely used, coal will become one of the production and life of human beings in an irreplaceable energy.Coal is millions of years of plant leaves and roots, stacked on the ground with a layer of very thick black humus, due to changes in the earth's crust constantly buried underground, long isolated from the air and under high temperature and pressure, after a series of complex physical and chemical changes and other factors, the formation of black however, this fossil, is the coal forming process.The thickness of coal seam in a coal mine and the crust drop speed and accumulation amount of plant remains. The crust decreased rapidly, the plant remains piled thick, the coal seam is thick, on the other hand, the crust decline slowly, the accumulation of plant remains thin, the mine coal seam is thin. The tectonic movement of the crust to the original level of coal seam folds and faults occur, some underground coal seam buried deeper, and squeezed to the surface, even above the ground, more likely to be found. There are some relatively thin coal seam, and the area is not large, so there is no value related to the formation of coal mining, so far not find the update statement.

- Q: What are carbon credits and how do they work?

- Carbon credits are a market mechanism designed to reduce greenhouse gas emissions. They work by assigning a monetary value to each ton of carbon dioxide or other greenhouse gases that are not released into the atmosphere. This value is assigned through a process called carbon offsetting, which involves investments in projects that reduce emissions, such as renewable energy projects or reforestation initiatives. These projects generate carbon credits, which can be bought and sold by companies or individuals to offset their own emissions. By purchasing carbon credits, entities can effectively compensate for their own carbon footprint and contribute to global efforts in mitigating climate change.

- Q: When will amines be fertilized?

- Carbon is the most commonly used varieties of amine fertilizer, with nitrogen and phosphorus fertilizer, fertilizer use, fertilizer is generally 120 days or so, the suitable conditions of temperature, moisture in the next 50 days after applying fertilizer best.Carbon amine is a white compound that is granular, plate-like or columnar crystalline. Because ammonium bicarbonate is a carbonate, it must not be placed with acids because the acid reacts with ammonium bicarbonate to form carbon dioxide, which causes ammonium carbonate to go bad. However, in the rural areas, ammonium carbonate and acid reaction are also used. The ammonium bicarbonate is placed in the vegetable greenhouse, and the greenhouse is sealed, and ammonium bicarbonate is placed at the top, adding hydrochloric acid. At this point, the amines react with hydrochloric acid to produce ammonium chloride, water, and carbon dioxide. Carbon dioxide can promote plant photosynthesis, increase vegetable production, and the resulting ammonium chloride can also be used as fertilizer again. Ammonium bicarbonate in the chemical formula of ammonium ion, is an ammonium salt, and ammonium salt and alkali can not be put together, so ammonium bicarbonate and sodium hydroxide or calcium hydroxide should not be put together

- Q: What are the challenges and opportunities of transitioning to a low-carbon economy?

- Transitioning to a low-carbon economy presents both challenges and opportunities. On the one hand, one of the major challenges is the need for significant changes in infrastructure, technology, and behavior. This transition requires substantial investments in renewable energy sources, energy-efficient buildings, and sustainable transportation systems. It also entails a shift away from fossil fuels, which have been deeply embedded in our economies for centuries. Another challenge is the potential economic impact on industries that heavily rely on carbon-intensive activities. Sectors such as coal mining, oil refining, and traditional manufacturing may face job losses and economic disruptions. The transition will require careful planning and support to ensure a just and inclusive transition for affected workers and communities. However, transitioning to a low-carbon economy also offers numerous opportunities. Firstly, it can spur innovation and create new industries and job opportunities. The development and deployment of renewable energy technologies, such as solar and wind power, can foster economic growth and provide employment in manufacturing, installation, and maintenance. It also promotes research and development in clean technologies, leading to breakthroughs and discoveries that can benefit various sectors. Secondly, transitioning to a low-carbon economy can improve public health and quality of life. By reducing reliance on fossil fuels, we can mitigate air pollution and its related health issues, such as respiratory problems and cardiovascular diseases. Additionally, investments in energy-efficient buildings can enhance comfort, reduce energy costs, and improve indoor air quality. Furthermore, transitioning to a low-carbon economy can enhance energy security and reduce geopolitical tensions. By diversifying energy sources and reducing dependence on fossil fuel imports, countries can increase their resilience to price fluctuations and geopolitical conflicts. This shift also promotes energy independence and reduces the need for costly military interventions in resource-rich regions. Lastly, transitioning to a low-carbon economy is essential for combating climate change and protecting the environment. By reducing greenhouse gas emissions, we can mitigate the impacts of global warming, such as extreme weather events, rising sea levels, and ecosystem disruptions. This transition allows us to preserve biodiversity, protect natural resources, and create a sustainable future for future generations. In conclusion, transitioning to a low-carbon economy brings challenges, including infrastructure changes, economic disruptions, and job losses. However, it also presents opportunities for innovation, job creation, improved public health, enhanced energy security, and environmental protection. With careful planning, collaboration, and support, the challenges can be overcome, and the opportunities can be maximized, leading to a more sustainable and prosperous future.

- Q: What are the carbon nanotube applications?

- The application of carbon nanotubes in composite materials: carbon nanotubes with nanoparticles in size effect, but also has high mechanical strength, good flexibility, high conductivity, unique properties, become the ideal reinforcement of polymer composites, is widely used in chemical industry, machinery, electronics, aviation, aerospace and other fields. But because of carbon nanotubes are easily assembled into bundles or wound, and compared with other nanoparticles, the surface is relatively inert, in common organic solvents or polymer materials dispersion in the low, which greatly restricts its application. Therefore, the surface of carbon nanotubes modified carbon nanotubes has become a research hotspot the polymer / composite material. At present, the domestic and foreign research on the surface modification of carbon nanotubes is mainly covalent and non covalent bond groups introduced on the surface, such as the use of the surface Chemical modification, surfactant modification, or by coating modification methods of carbon nanotube polymer molecules. In recent years is presented. The ultraviolet irradiation, plasma radiation modification and processing method. The surface modification of carbon nanotubes for polymer composites can significantly improve the mechanical properties, electrical properties and thermal properties.

- Q: The printed document will be marked on the document name: carbon copy, no combination number, two links...... What's the meaning of this? What is the connection between the infinite and the two? I MMM

- Carbon free copy of a few, several refers to a few colors, that is, a few single! Is that a joint edge is what two of what is triple what you said and so on the boundless contact I estimate that he designer or boss tell you to explain things without Bian Lian refers to not say a contact department or (what) no Bian Lian case is a version of the paper change down on it, but the color edge contact is not the same a version of a few joint Bian Lian have changed several times I say you understand it?

- Q: What are the consequences of increased carbon emissions on urban areas?

- Increased carbon emissions have numerous consequences on urban areas. Firstly, it leads to a rise in air pollution, contributing to respiratory issues and increased health risks for the population. Additionally, carbon emissions contribute to the greenhouse effect, leading to higher temperatures and exacerbating the urban heat island effect, which can result in discomfort, heat-related illnesses, and increased energy demands for cooling. Moreover, increased carbon emissions contribute to climate change, leading to more frequent and intense extreme weather events like storms and heatwaves, which pose significant threats to urban infrastructure, public safety, and economic stability. Overall, the consequences of increased carbon emissions on urban areas are detrimental to both the environment and human well-being.

- Q: What are the different types of carbon-based drugs?

- There are several categories in which carbon-based drugs can be classified, based on their chemical structure and mode of action. One of the most common categories is alkaloids, which are naturally occurring compounds found in plants and have powerful pharmacological effects. Examples of carbon-based alkaloid drugs include morphine, codeine, and cocaine. Another category of carbon-based drugs is steroids. Steroids are compounds characterized by a carbon skeleton consisting of four fused rings. They are widely used in medicine because of their anti-inflammatory and immunosuppressive properties. Examples of carbon-based steroid drugs include cortisone, prednisone, and estrogen. Additionally, carbon-based drugs can be classified as nonsteroidal anti-inflammatory drugs (NSAIDs). These drugs work by inhibiting the action of cyclooxygenase enzymes, which reduces pain, inflammation, and fever. Common carbon-based NSAIDs include aspirin, ibuprofen, and naproxen. Furthermore, carbon-based drugs can be categorized as antibiotics. These are compounds derived from microorganisms or synthesized artificially that hinder the growth of bacteria or other microorganisms. Examples of carbon-based antibiotic drugs include penicillin, tetracycline, and erythromycin. Lastly, carbon-based drugs can also be synthetic compounds designed to target specific receptors or pathways in the body. These drugs are often created through extensive research and testing to treat various diseases and conditions. Examples of such drugs include cholesterol-lowering statins, antipsychotic medications, and anti-cancer drugs. To sum up, carbon-based drugs can be classified into alkaloids, steroids, NSAIDs, antibiotics, and synthetic compounds. Each category consists of drugs with diverse chemical structures and mechanisms of action, allowing for a wide range of therapeutic applications in the field of medicine.

- Q: How does carbon affect the quality of indoor air?

- The quality of indoor air can be significantly affected by carbon. Carbon dioxide (CO2) is a major contributor to carbon in indoor air and is produced when humans and animals respire. High levels of CO2 can cause discomfort, including drowsiness, headaches, and difficulty concentrating. Another carbon compound that can be found in indoor air is carbon monoxide (CO), which is mainly present due to incomplete combustion of fossil fuels in stoves, fireplaces, and furnaces. Carbon monoxide is extremely toxic and can be life-threatening if it reaches high concentrations. In addition to these direct sources of carbon, volatile organic compounds (VOCs) can also impact indoor air quality. VOCs like formaldehyde, benzene, and toluene are released from various sources such as building materials, furniture, cleaning products, and tobacco smoke. These VOCs can have harmful effects on health, including irritation of the eyes, nose, and throat, headaches, dizziness, and in some cases, long-term health risks such as cancer. To maintain good indoor air quality, it is crucial to monitor and control the levels of carbon compounds in the air. Adequate ventilation is essential to ensure fresh air circulation and reduce the concentration of CO2 and other pollutants. Regular maintenance and inspection of appliances that burn fuel can prevent the accumulation of carbon monoxide. Choosing low-VOC or VOC-free materials and products, as well as refraining from smoking indoors, can help minimize the emission of harmful carbon compounds.

- Q: Recently bought an alarm clock, it is recommended to use carbon batteries. Nanfu battery is not good for the movement.

- Yes, a lot of people do not pay attention to, the Nanfu battery, strange carbon batteries say it is really rare, generally small supermarkets are not only basic, and is strongly alkaline. Therefore, it is best to go to a large supermarket or electrical store try, there are generally sold there, and many types, the choice will be more.

Send your message to us

Calcined Petroleum Coke as Recarburizer for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 19.3

- Supply Capability:

- 1003 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords