Calcined Petroleum Coke as Injection Coke for Steel Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.2

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

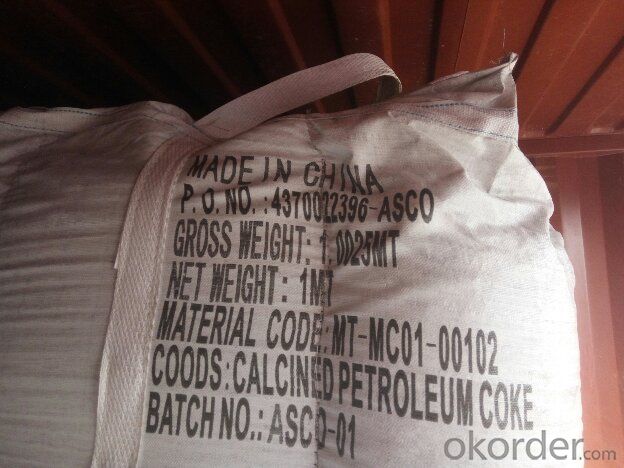

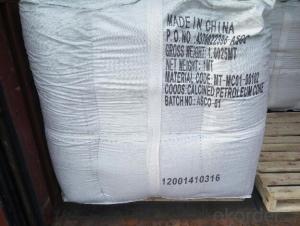

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: What is carbon neutral?

- Carbon neutral refers to achieving a state where the amount of carbon dioxide emitted into the atmosphere is balanced with the amount that is removed or offset. It is a widely used term in the context of addressing climate change and reducing greenhouse gas emissions. To become carbon neutral, one must first assess their carbon footprint, which involves calculating the greenhouse gases produced through activities like energy consumption, transportation, and waste management. Once the emissions are identified, steps are taken to decrease them through various methods, such as improving energy efficiency, utilizing renewable energy sources, and adopting sustainable practices. Although it is challenging to completely eliminate carbon emissions, it is crucial to reduce them. In cases where complete elimination is not possible, carbon offsets can be employed to compensate for the remaining emissions. Carbon offsets involve investing in projects that reduce or remove greenhouse gases from the atmosphere, like reforestation, renewable energy initiatives, or methane capture projects. By achieving carbon neutrality, individuals, organizations, or activities can assert that they are not contributing to the increase of greenhouse gases in the atmosphere. This is a significant objective in the battle against climate change, as it helps mitigate the adverse effects of carbon emissions and promotes a more sustainable and environmentally friendly future.

- Q: What are the properties of carbon fibers?

- Carbon fibers possess a range of remarkable attributes, rendering them a distinctive and adaptable material. One noteworthy characteristic is their exceptional strength-to-weight ratio. Carbon fibers exhibit tremendous strength, often surpassing that of steel, while also being significantly lighter. This quality makes them exceptionally well-suited for industries such as aerospace and automotive, where high strength and low weight are essential. Another significant attribute of carbon fibers is their stiffness. They possess a high degree of rigidity, ensuring minimal deformation when subjected to applied loads. This property proves advantageous in applications that require stability and rigidity, such as the construction of sporting goods like tennis rackets or golf clubs. Additionally, carbon fibers display outstanding resistance to chemical corrosion. They exhibit a high level of resistance to the detrimental effects of chemicals or corrosive substances, making them highly suitable for use in harsh environments. Industries such as chemistry or offshore structures prefer carbon fibers due to this property. Furthermore, carbon fibers have a low thermal expansion coefficient, indicating minimal expansion when exposed to heat. This characteristic is vital in applications where thermal stability is crucial, such as the manufacturing of high-temperature components like turbine blades or heat shields. Moreover, carbon fibers possess excellent fatigue resistance, enabling them to endure repeated loading and unloading cycles without significant damage. This attribute is particularly advantageous in applications subjected to cyclic or dynamic stresses, including the construction of sports equipment or aerospace structures. Lastly, carbon fibers exhibit excellent electrical conductivity. They efficiently conduct electricity, making them suitable for applications that require electrical conductivity, such as lightning strike protection in the aerospace industry or the production of electronic devices. In summary, the high strength-to-weight ratio, stiffness, chemical resistance, low thermal expansion, fatigue resistance, and electrical conductivity of carbon fibers establish them as a highly sought-after material in various industries.

- Q: What are the industrial uses of diamonds?

- Due to their exceptional physical properties, diamonds have a wide range of industrial uses. One of the most common applications is in the manufacturing of cutting and grinding tools. Diamond-tipped saw blades, drill bits, and grinding wheels are highly sought after for their superior hardness and abrasion resistance. These tools are in high demand for cutting and shaping hard materials such as concrete, ceramics, and metals. In the electronics industry, diamonds are extensively utilized. They serve as heat sinks in high-power electronic devices and as abrasive materials for polishing and lapping electronic components. The thermal conductivity of diamonds allows them to efficiently dissipate heat, making them ideal for electronic devices that generate a significant amount of heat during operation. Moreover, diamonds play a crucial role in the production of specialized windows, lenses, and prisms used in various scientific and industrial applications. Their optical properties, including high refractive index and low dispersion, make them invaluable for creating precision optics employed in lasers, spectroscopy, and telecommunications. Additionally, diamonds have niche applications in the medical and dental fields. Their exceptional hardness and ability to retain sharp edges make them suitable for surgical tools like scalpels and dental drills. Diamond coatings are also applied to medical implants and prosthetics to enhance wear resistance and biocompatibility. Lastly, the oil and gas industry relies on diamonds for drilling and exploration purposes. Diamond drill bits are capable of penetrating extremely hard rock formations, making them essential for extracting oil and natural gas from deep beneath the Earth's surface. In summary, diamonds have vast and diverse industrial uses, ranging from cutting and grinding tools to electronics, optics, medicine, and even oil and gas exploration. The unique properties of diamonds make them indispensable in numerous industrial applications, contributing to advancements in various fields.

- Q: How does carbon impact the formation and intensity of hurricanes?

- The formation and intensity of hurricanes are significantly influenced by carbon, specifically carbon dioxide. The rise in atmospheric carbon dioxide levels is a result of increased carbon emissions from human activities such as burning fossil fuels, deforestation, and industrial processes. This increase in carbon dioxide contributes to global warming. Global warming is caused by the greenhouse effect and leads to higher sea surface temperatures. These warmer ocean waters provide the necessary energy and moisture for hurricanes to form and strengthen. As the atmosphere warms, it can hold more water vapor, which acts as fuel for hurricanes, making them more powerful and intense. The warming of the atmosphere also changes the conditions that affect hurricane formation. It alters the wind shear, which is the difference in wind speed and direction at different altitudes. Low wind shear is favorable for hurricane development as it allows the storm to organize and gain strength. However, global warming can disrupt this balance and create unfavorable wind shear patterns, hindering hurricane formation. Additionally, the increased levels of carbon dioxide in the atmosphere contribute to ocean acidification. When carbon dioxide dissolves in seawater, it forms carbonic acid, which lowers the pH of the ocean. Acidic waters have detrimental effects on marine life, including coral reefs. Coral reefs act as natural barriers against storm surges during hurricanes, but their degradation weakens their ability to protect coastal communities. In conclusion, carbon emissions and the subsequent increase in carbon dioxide levels have a significant impact on the formation and intensity of hurricanes. The warming of the atmosphere and ocean, along with changes in wind shear patterns, create conditions that favor the development and intensification of hurricanes. Additionally, ocean acidification resulting from excessive carbon dioxide levels weakens natural defenses against storm surges. It is essential to address carbon emissions and reduce our carbon footprint to mitigate the potential consequences of climate change and its impact on hurricanes.

- Q: What is carbon dioxide?

- Carbon dioxide (CO2) is a colorless and odorless gas composed of one carbon atom bonded to two oxygen atoms. It is naturally present in the Earth's atmosphere and is also produced by human activities such as burning fossil fuels and deforestation. Carbon dioxide plays a crucial role in the Earth's carbon cycle and is a greenhouse gas, contributing to global warming and climate change.

- Q: Carbon fiber refractory?

- 3, pre oxidized carbon fiber cloth, can withstand 200--300 degrees of high temperature

- Q: How does carbon impact the prevalence of heatwaves?

- Carbon impacts the prevalence of heatwaves by contributing to the greenhouse effect. When carbon dioxide and other greenhouse gases are released into the atmosphere, they trap heat from the sun, leading to a rise in global temperatures. This increase in temperature makes heatwaves more frequent, intense, and longer-lasting, posing significant risks to human health, ecosystems, and infrastructure.

- Q: What does carbon burning mean?

- As the word says, it is boiled and boiled with carbon

- Q: The relative molecular mass was between 120-150. The testThe organic matter M, which contains only carbon, hydrogen and oxygen, was measured by mass spectrometer. The relative molecular mass was between 120-150. The mass fraction of oxygen element measured by experiment is 48.48%, the ratio of hydrocarbon to mass is 15:2, and only COOH in M molecule is measured by infrared spectrometer. Then the M formula is?

- The mass fraction of oxygen element is 48.48%, the mass fraction of hydrocarbon is =51.52%, and the mass ratio is 15:2. The mass fraction of carbon is =51.52%x15/ (15+2) =45.46%, and the mass fraction of hydrogen is =51.52%x2/ (15+2) =6.06%The atomic number of C, H and O is higher than that of =45.46%/12:6.06%/1:48.48%/16=3.79:6.06:3.03Molecules contain only COOH, and oxygen atoms must be even numbers.Therefore, the number of atoms in C, H and O can be reduced to =5:8:4, which may be C5H8O4, and the relative molecular weight is 132

- Q: What are the different types of carbon-based composites?

- There are several different types of carbon-based composites, each with unique properties and applications. Some of the most common types include carbon fiber reinforced polymers (CFRPs), carbon nanotube composites, and carbon fiber reinforced ceramics. Carbon fiber reinforced polymers (CFRPs) are perhaps the most well-known and widely used carbon-based composites. They consist of carbon fibers embedded in a polymer matrix, such as epoxy resin. CFRPs are lightweight, yet incredibly strong and stiff, making them ideal for applications where weight reduction and high strength are crucial, such as aerospace, automotive, and sporting goods industries. Carbon nanotube composites are another type of carbon-based composite that have gained significant attention in recent years. Carbon nanotubes are cylindrical structures made of carbon atoms arranged in a hexagonal lattice. When incorporated into a composite material, they enhance its mechanical, thermal, and electrical properties. Carbon nanotube composites have potential applications in fields such as electronics, energy storage, and structural materials. Carbon fiber reinforced ceramics combine the high strength and stiffness of carbon fibers with the exceptional high-temperature resistance of ceramics. These composites are commonly used in industries that require materials capable of withstanding extreme temperatures, such as aerospace, defense, and nuclear sectors. Carbon fiber reinforced ceramics offer an excellent balance between strength, thermal stability, and low weight. Other types of carbon-based composites include carbon fiber reinforced metals, where carbon fibers are embedded in a metal matrix, and graphene composites, which incorporate graphene sheets into a polymer or metal matrix. These composites offer unique properties such as high electrical conductivity, thermal stability, and mechanical strength, opening up possibilities for applications in areas like electronics, energy storage, and structural materials. Overall, carbon-based composites offer a diverse range of properties and applications, making them invaluable materials in various industries that require lightweight, strong, and durable materials.

Send your message to us

Calcined Petroleum Coke as Injection Coke for Steel Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.2

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords