Calcined Petroleum Coke as Injection Coke for Steel Plants

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.3

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Intrduction

Carbon additive to ningxia production of anthracite as raw material, after washing, crushing, high temperature calcination, filter, etc. Craft refined and become.This is after the anthracite calcination generated high carbon content and low volatile component of the new product, is an ideal raw material to make steel.

Calcined Petroleum Coke comes from delayed coke which extracted from oil refinery. Although Calcined Petroleum Coke contains a little bit higher level of sulfur and nitrogen than pitch coke, the price advantage still makes it widely used during steel-making and founding as a kind of carbon additive/carburant.

Features

In the smelting process for reducing agent. Performance: replace the traditional oil carbon additive, decrease the cost of steelmaking. Features: low ash. low sulfur,low phosphorus, high calorific value. High ratio resistance,high mechanical strength,high chemistry activity. It is mainly used for metallurgy reductant inoculants, casting, refractory materials, machinery, electronics and other fields.Good quality

1) high absorption rate, it can be absorbed up to 90%.

2) absorbed more quickly than other carbon additive; no residue remains in furnace.

3) low Sulfur, the lowest can reach below 0.20%; low nitrogen, normally below 200ppm (0.02%)

Specifications

CPC | |||

F.C.% | 98.5MIN | 98.5MIN | 98MIN |

ASH % | 0.8MAX | 0.8MAX | 1MAX |

V.M.% | 0.7 MAX | 0.7 MAX | 1 MAX |

SULFUR % | 0. 5MAX | 0. 7MAX | 1MAX |

MOISTURE % | 0.5MAX | 0.5MAX | 1MAX |

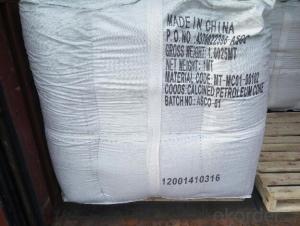

Pictures

FAQ:

(1)CPC could be as fuel

Petroleum coke is a material relatively low in cost and high in heat value and carbon content with good chemical stability, making it an efficient and costeffective fuel for producing metal, brick and related products.

(2)CPC could be as Graphite Electrodes

Graphite can be produced from lowsulfur needle petroleum coke, which must be heated above 5,432 degrees Fahrenheit.

(3)CPC could be as Anodes

Calcined petroleum coke, often low in sulfur and metallic impurities, is used to make anodes for

the smelting industry.Calcined petroleum coke is mixed with coal tar pitch in the production of

anodes.

- Q: When will amines be fertilized?

- Avoid high temperature applications. The temperature is below 20 DEG C when ammonium bicarbonate is relatively stable, high temperature or moisture in the product exceeds a certain standard, is easy to be decomposed into ammonia and carbon dioxide emissions in the air, causing loss of nitrogen fertilizer. According to the test results show that the winter crops better than urea and ammonium carbonate. Because the temperature is low in winter, the process of urea conversion is long, but the ammonium carbonate can be directly absorbed without conversion. It is beneficial to the early growth and fast growth of winter crops. In addition, when applied to the soil ammonium bicarbonate, ammonium ion dissociation can be directly by soil colloid adsorption, and urea to winter crop soil, urea was dissolved in the soil solution in the molecular state, but not by soil colloid adsorption, it is more likely to cause the loss of nutrientsThe use of ammonium bicarbonate does not mix with alkaline fertilizers, which can lead to loss of nitrogen nutrients, resulting in low fertilizer efficiency. Using ammonium hydrogen carbonate friends should know that not with urea and ammonium hydrogen carbonate mixed fertilizer, ammonium bicarbonate if mixed with urea, urea conversion rate will not only extend, and will accelerate the volatilization of urea.Ammonium bicarbonate extremely volatile, so to avoid the ground using ammonium bicarbonate, ammonium bicarbonate has strong corrosion on leaf blade, easy to burn, can not be used as a foliar spray. There is one thing to note is that if the soil drought, even deep application coverage, can not be dissolved in ammonium bicarbonate, better soil moisture using ammonium bicarbonate, can reduce the volatilization loss, improve efficiency

- Q: How does carbon impact the stability of desert ecosystems?

- Carbon can have both positive and negative impacts on the stability of desert ecosystems. On one hand, carbon is an essential element for all living organisms and is a key component of organic matter. It plays a crucial role in the processes of photosynthesis, respiration, and decomposition, which are vital for the survival and growth of plants and other organisms in deserts. Carbon dioxide, a form of carbon, is taken in by plants during photosynthesis to produce glucose and oxygen, providing the necessary energy for their growth. This promotes the stability of desert ecosystems by supporting primary productivity and the food web. However, the excessive release of carbon into the atmosphere, primarily through human activities such as burning fossil fuels and deforestation, has led to an increase in greenhouse gases, including carbon dioxide. This leads to global warming and climate change, which have significant negative impacts on desert ecosystems. Rising temperatures can alter the delicate balance of desert ecosystems, affecting the distribution and abundance of plant and animal species. Some plants may struggle to adapt to the changing climate, while others may benefit, leading to shifts in species composition and potential loss of biodiversity. Moreover, increased carbon dioxide levels can also affect the water availability in desert ecosystems. Elevated carbon dioxide levels can result in increased water-use efficiency in plants, allowing them to conserve water. This can be beneficial in water-limited environments like deserts, as it helps plants to survive under drought conditions. However, this can also lead to changes in water dynamics, impacting the availability of water resources for other organisms in the ecosystem. In summary, carbon is essential for the stability of desert ecosystems as it supports primary productivity and the functioning of food webs. However, the excessive release of carbon into the atmosphere contributes to climate change, which negatively impacts desert ecosystems by altering species distribution, reducing biodiversity, and affecting water availability. It is crucial to mitigate carbon emissions and promote sustainable practices to ensure the long-term stability and resilience of desert ecosystems.

- Q: What are the advantages of carbon-based fertilizers?

- Farmers and gardeners favor carbon-based fertilizers for several reasons. Firstly, these fertilizers, such as compost and manure, are organic and derived from natural sources, devoid of synthetic chemicals. This eco-friendly quality reduces the risk of water pollution and soil degradation. Secondly, carbon-based fertilizers contain ample organic matter, enhancing soil structure and water retention. This proves especially helpful in areas with infertile soil or frequent droughts, as it conserves moisture and prevents nutrient loss. Furthermore, these fertilizers foster the growth of beneficial microorganisms in the soil. These microorganisms gradually break down organic matter, releasing essential nutrients and ensuring a steady supply to plants. The result is improved plant health and a decreased likelihood of nutrient imbalances or deficiencies. Additionally, carbon-based fertilizers prove cost-effective in the long run. Though they may require more effort and time initially, they can be produced on-site through composting or sourced locally from farms or livestock operations. This reduces the need for expensive chemical fertilizers and minimizes transportation costs. Lastly, carbon-based fertilizers aid in carbon sequestration and contribute to combating climate change. By utilizing organic waste materials as fertilizers, they divert them from landfills, where they would emit greenhouse gases. Instead, they are recycled into the soil, increasing its carbon content and promoting soil health. In summary, carbon-based fertilizers offer numerous advantages in terms of sustainability, soil fertility, cost-effectiveness, and environmental impact. Their usage can yield healthier plants, improved soil quality, and a more sustainable and resilient agricultural system.

- Q: What is the carbon content of different types of rocks?

- The carbon content of different rock types can vary greatly, with rocks primarily consisting of minerals that do not contain much carbon. However, certain rocks can have varying amounts of carbon due to the presence of organic matter or other carbon-rich materials. Sedimentary rocks, like limestone and coal, have the potential to contain higher levels of carbon. Limestone is mainly made up of calcium carbonate, but it can also have small amounts of organic matter or carbonates that contribute to its carbon content. In contrast, coal is a sedimentary rock formed from decomposed and carbonized plant material, resulting in a high carbon content ranging from 50% to 90%. Igneous rocks, formed from solidified molten material, generally have very low carbon content because the process of magma crystallization does not involve the inclusion of carbon-rich materials. However, there are exceptions in certain cases where magma interacts with carbon-rich fluids or rocks, leading to the formation of carbon-bearing minerals like graphite or diamond. Metamorphic rocks, formed through the transformation of existing rocks under high pressure and temperature, may contain varying amounts of carbon. The carbon in metamorphic rocks can come from the original rock or be introduced during the metamorphism process. For example, carbonaceous material in shale or limestone can be converted into graphite or other carbon-rich minerals during metamorphism. It is important to note that although some rocks may have significant carbon content, they are not considered a major reservoir of carbon in the Earth's carbon cycle. The majority of carbon is stored in the atmosphere as carbon dioxide, in the oceans, or in organic matter within living organisms.

- Q: What are carbon nanotubes?

- Carbon nanotubes, characterized by their unique structure, are cylindrical formations made solely of carbon atoms. These nanotubes, aptly named due to their minuscule diameter of a few nanometers, can attain remarkable lengths of several centimeters. The distinctive structure of carbon nanotubes grants them extraordinary properties. They exhibit exceptional strength and mechanical characteristics, surpassing steel by a factor of 100 while only weighing one-sixth as much. Furthermore, they possess remarkable thermal and electrical conductivity. Categorically, carbon nanotubes can be classified into two primary types: single-walled carbon nanotubes (SWCNTs) and multi-walled carbon nanotubes (MWCNTs). Single-walled nanotubes consist of a solitary layer of rolled carbon atoms, whereas multi-walled nanotubes comprise several layers of these nested formations. The exceptional properties of carbon nanotubes enable their diverse applications across numerous fields. In the realm of electronics, their high electrical conductivity renders them suitable for use as transistors and interconnects. Additionally, their substantial surface area and electrical conductivity make them ideal for incorporation into energy storage devices like batteries and supercapacitors. Within materials science, carbon nanotubes reinforce composites, enhancing their strength and reducing their weight. Moreover, they exhibit potential applications in medicine as drug delivery systems and imaging agents. Ongoing research endeavors strive to deepen our understanding and harness the potential of carbon nanotubes. Nonetheless, challenges persist regarding their large-scale production, cost-effectiveness, and possible health and environmental ramifications. Overall, carbon nanotubes represent an exhilarating and promising domain of nanotechnology, offering vast possibilities for advancements in various fields.

- Q: How does carbon dioxide contribute to ocean acidification?

- Carbon dioxide contributes to ocean acidification through a process called carbonic acid formation. When carbon dioxide dissolves in seawater, it reacts with water molecules to form carbonic acid. This reaction increases the concentration of hydrogen ions in the water, leading to a decrease in pH, making the water more acidic. As carbon dioxide emissions from human activities, particularly the burning of fossil fuels, continue to increase, more and more carbon dioxide is being absorbed by the oceans. This excessive absorption is disrupting the natural equilibrium that exists between carbon dioxide in the atmosphere and in the ocean, resulting in a surplus of carbon dioxide in the seawater. The increased acidity of the seawater can have severe consequences for marine life. Many marine organisms such as corals, shellfish, and certain types of plankton depend on calcium carbonate to build their shells or skeletons. However, in more acidic water, the availability of carbonate ions, which are necessary for the formation of calcium carbonate, decreases. As a result, these organisms struggle to build and maintain their protective structures, making them more vulnerable to predation and other threats. Ocean acidification also affects the growth, development, and behavior of many other marine species. For instance, acidification can disrupt the reproductive cycles of fish and alter the behavior of some species, making them more prone to predation or negatively impacting their ability to find food or mates. Furthermore, ocean acidification can have cascading effects on entire marine ecosystems. Many species in the ocean are interconnected in complex food webs, and any disruption to one species can have far-reaching consequences on others. For example, if the population of a certain fish species declines due to the impacts of acidification, it can have a ripple effect on the entire food chain, affecting the abundance and distribution of other species. In summary, carbon dioxide contributes to ocean acidification by dissolving in seawater and forming carbonic acid, which increases the concentration of hydrogen ions and decreases the pH. This process can have detrimental effects on marine organisms, particularly those that rely on calcium carbonate for their shells or skeletons. It can also disrupt the growth, development, and behavior of various marine species and have cascading impacts on entire ecosystems.

- Q: What are the consequences of increased carbon emissions on coastal regions?

- Increased carbon emissions have significant consequences on coastal regions. One of the most notable impacts is sea-level rise, caused by the warming of the planet and the subsequent melting of glaciers and ice sheets. This rise in sea levels can lead to coastal erosion, flooding, and the loss of coastal habitats. Additionally, carbon emissions contribute to ocean acidification, which harms marine life and coral reefs. The combination of these effects poses a threat to coastal communities, economies, and ecosystems, highlighting the urgent need for global action to reduce carbon emissions and mitigate the consequences.

- Q: What are the different types of carbon-based drugs?

- There are several categories in which carbon-based drugs can be classified, based on their chemical structure and mode of action. One of the most common categories is alkaloids, which are naturally occurring compounds found in plants and have powerful pharmacological effects. Examples of carbon-based alkaloid drugs include morphine, codeine, and cocaine. Another category of carbon-based drugs is steroids. Steroids are compounds characterized by a carbon skeleton consisting of four fused rings. They are widely used in medicine because of their anti-inflammatory and immunosuppressive properties. Examples of carbon-based steroid drugs include cortisone, prednisone, and estrogen. Additionally, carbon-based drugs can be classified as nonsteroidal anti-inflammatory drugs (NSAIDs). These drugs work by inhibiting the action of cyclooxygenase enzymes, which reduces pain, inflammation, and fever. Common carbon-based NSAIDs include aspirin, ibuprofen, and naproxen. Furthermore, carbon-based drugs can be categorized as antibiotics. These are compounds derived from microorganisms or synthesized artificially that hinder the growth of bacteria or other microorganisms. Examples of carbon-based antibiotic drugs include penicillin, tetracycline, and erythromycin. Lastly, carbon-based drugs can also be synthetic compounds designed to target specific receptors or pathways in the body. These drugs are often created through extensive research and testing to treat various diseases and conditions. Examples of such drugs include cholesterol-lowering statins, antipsychotic medications, and anti-cancer drugs. To sum up, carbon-based drugs can be classified into alkaloids, steroids, NSAIDs, antibiotics, and synthetic compounds. Each category consists of drugs with diverse chemical structures and mechanisms of action, allowing for a wide range of therapeutic applications in the field of medicine.

- Q: Why are biological molecules carbon based molecular aggregates?

- Because living things are living organisms, most of them consist of organic compounds, which are carbon compounds, and carbon chains are the main body

- Q: How does carbon dioxide affect the pH of soil?

- Carbon dioxide can lower the pH of soil by reacting with water to form carbonic acid, which increases the acidity of the soil.

Send your message to us

Calcined Petroleum Coke as Injection Coke for Steel Plants

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20.3

- Supply Capability:

- 1012 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords