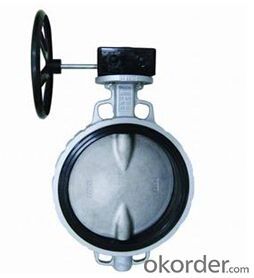

Butterfly Valve DN80 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required.

2.Main Features of the Manual Wafer Butterfly Valve

1. Small in size and light in weight, easy instillation and maintenance. It can be mounted wherever needed

2. The material of valve body: cast iron, cast steel, cast stainless steel and so on.

3. Pressure grade: 1.6Mpa, 4.0Mpa, 6.4Mpa

4. Connecting type: flange coupling

5. Temperature range: normal temperature -20---230ºC the thermal slug type -60---450ºC

6. Operation form: automatic open or close

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

Size: DN50-DN1000

End flange: ANSI B 16.1,EN1092,AS2129

Face to face: ANSI B 16.10

Top flange: ISO 5211

Normal pressure: PN1.0/1.6MPa(150/200PSI)

Body: CI/DI/WCB/ALB/CF8/CF8M

Disc: DI/ALB/Rubber lined Disc/1.2501/1.4529/CF8/Hastelloy Alloy/Monel

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: HowdyWas taking apart a screw down NR valve and screw lift valve and noticed the spindles were made out of different materials. Brass and Steel.I am aware that brass is non corrosive but why use steel in the other valve? Is it due to their operation, do they come or not come in contact with fluids? Is one cheaper than the other?The screw lift globe valve had a steel spindle and the screw down nr glove valve had a brass spindle.Also, if anyone knows what materials are used in the valve lid and seat are made of.Any ideas?Cheers

- Brass is used in some cases because it it less likely to corrode. It is used in other cases because it is softer than steel and can act as a bearing surface. Steel is usually used because of its strength relative to brass. In some cases they are used in combination so the steel surface and the brass surfaces compliment each other to provide a smooth sliding surface. Bronze is also a popular material for some valves and parts of other valves. Usually in water or steam service. Many times the valve seats are made from a harder material such as stellite. See site below for more info on stellite.

- Q: large veins contain one way valves, which keep the blood flowing in one direction. why dont large arteries need similar valves?

- The heart actively pumps blood forward. That keeps it moving in one direction. On the other hand, venous flow is more passive.

- Q: Hi. I am planning to install new kitchen faucet and noticed that there are two shut off valves under the sink. One of them is badly rusted and needs to be replaced. I noticed that it is connected to three pipes (one of which is kitchen faucet). The other is clearly water coming in. What is the third one connected to wall? Also how should I go about replacing this? Anything that I should be careful of? Thank you.Here's picture of shutoff valve.

- can't get your picture to load. is it the hot? is there a dishwasher a wee bit away from sink? is there something water related on the other side of the wall?

- Q: We have a wall mounted shower head as well as a ceiling mounted shower head. Suddenly the turning valve for the wall mounted head does not work, only the ceiling one does. Is this stripped. Can it be repaired with a marble wall? I have a photo if needed. Thank you ahead of time. Patrick

- The mixing valve is in the handle that turns the water on. You don't need to take down the wall to get at it. The handle come off including any cover plate and the valve is right behind it. Be careful not drop/lose any screws or washers. They are small. The home center sells replacements for certain brands so get that information.

- Q: Is there a devise to reverse the flow to a cylinder. Not the pump. But a inline flow deverter that would shift the flow from one side of the cylinder to the other at the end of the stroke automatically without a person interjecting.ie it extends fully then the flow reverses retracting it fully. Then the flow reverses, and it extends fully and so on.Preferably, with as little lag as possible during the transition.I want the pump to run constantly(not reversing) and the cylinder to run constantly. Do not worry about the heat generated.Would love something that ran off the main cylinder(like a secondary piston or valve that would opendivert flow at the end of the stroke) through linkage. But, I am open to electronics if need be. Further more want the return to be metered so that the push and pull forces will be the same(metered through a smaller opening to adjust for the rod).Thankyou

- Electrically operated hydraulic changeover valve would be simplest. Then all you need is switches to operate first 1 solenoid, then the other, reversing flow. These could be as simple as microswitches operating latching relays to control the valve. An accumulator should be fitted to reduce hydraulic shock from a sudden direction change.

- Q: When my son was three I switched Dr's for him. The new doctor said has he always had a heart murmur I said no that's the first I've heard of it so we went for test. Anyway heart specialist did all tests said my son had Bav a valve disorder in the heart. He said it is very common. However everyone I've ever talked to has never heard of it. My question is does anyone have this what is your story and have you had to have your valve replaced. My son is very healthy active I'm just worried. Any help would be greatly appreciated....thank you!!

- it is a common cause of murmurs in children, and ordinarily they grow out of it, you can relax.

- Q: I just got my water pump replaced on my Peerless boiler. Now my backflow valve is always dripping. I am unsure if I should cap it off or if the dripping will stop over time. It seems that there is some pressure comming from the vent. What should I do??

- The seal may be worn. Call back the company that installed the pump...

- Q: I am a junior piping engineer. I want to know what is the meaning of term Triple Eccentric in Triple Eccentric Butterfly ValveButterfly Valve. So kindly enlighten me.

- Good question but I think I found your answer. Hope this helps. Triple eccentric means:- 1)First eccentric is the offset between the shaft centre line and the disc trunnion centre line. 2)Second eccentric is the offset between the body centre line and the disc centre line. 3)The third and the most important is the eccentric in the sealing(multiple) itself such that if you draw a imaginary contour line between the sealing shape vs the body centre,It becomes a cone with one side flat on surface.(I hope my words are clear enough to make you understand). The reason for this shape is because it gives better sealing ability for the valve.eg:- Fire safe valves are triple eccentric valves which are also called pyrogenic valves.The sealings are multiple in nos. and together they form a pyrogenic shape therefore this sealing is also called pyrogenic sealing.

- Q: Kenmore washer ,cold water trickles in, pressure from faucet OK. Must entire valve be replaced?

- see if you can find a manuel on it also try tracing the wires that go to the valve and back track from there. there is also water level switches and tempture switches that might be messed up

- Q: Can anyone tell me what to do if i know that I have the type of valve stem that was recalled TR413chrome?? Will they replace them for free since they are a recall or do I have to dish out some more $$ to fix the problem??? The company that sold them to me is in Florida (Wheelmax) and I am in Mass. Not sure what to do to avoid having to pay out more $$ to have them replaced...any help is greatly appreciated

- Get okorder Take care.

Send your message to us

Butterfly Valve DN80 Turbine Type with Hand Wheel BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords