102 Aluminum Coil for Interior Wall System - Brushed Coating Washington

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Brushed Coating Aluminum Coil for Interior Wall System

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Brushed Coating Aluminum Coil for Interior Wall System

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Brushed Coating Aluminum Coil for Interior Wall System

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

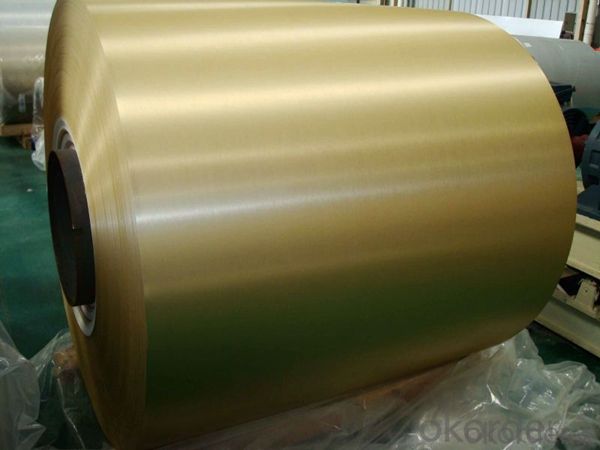

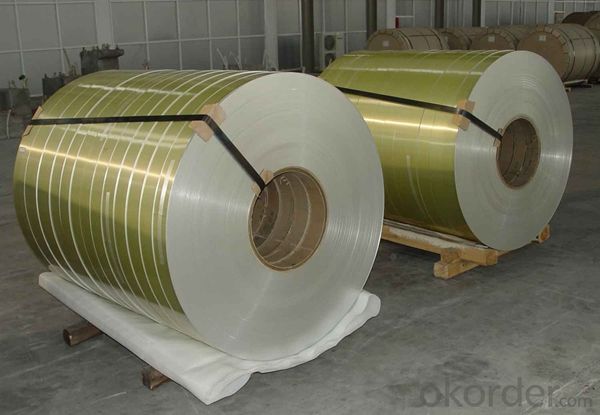

5. Image of Brushed Coating Aluminum Coil for Interior Wall System

6. Package and shipping of Brushed Coating Aluminum Coil for Interior Wall System

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the effects of casting temperature on ductility of aluminum coil?

- The tensile strength and ductility increase with the solid solution insulation time, and reach best fit at 1 hour. Continue thermal insulation, and the tensile strength will change little while the ductility will reduce. This is because the solid solution over insulation will cause the work pieces crystallize so that the large crystal reduce the plasticity.

- Q: How long do aluminum coils typically last?

- The typical lifespan of aluminum coils is approximately 15 to 20 years, but their longevity is heavily influenced by various factors including the quality of the aluminum, the installation process, and the maintenance and care given to them. The lifespan of the coils can be significantly prolonged by regularly maintaining them, such as by cleaning the coils and ensuring adequate airflow. Moreover, their durability can also be affected by environmental factors like exposure to severe weather conditions and corrosive substances. Hence, ensuring proper care and maintenance is crucial to guarantee the extended lifespan of aluminum coils.

- Q: This question asks for the distinctions between two types of metal coils: aluminum and iron.

- <p>Aluminum coil and iron coil differ in several aspects. Aluminum coil is lightweight, corrosion-resistant, and has good electrical conductivity, making it ideal for applications like electrical wiring and packaging. Iron coil, on the other hand, is heavier, stronger, and more magnetic, commonly used in construction and manufacturing for reinforcement and structural support. Additionally, iron is more prone to rust compared to aluminum, which is more resistant to corrosion. The cost and availability of these materials also vary, with aluminum being more abundant and less expensive than iron.</p>

- Q: Are aluminum coils suitable for chemical processing applications?

- Indeed, aluminum coils prove to be fitting for chemical processing applications. Renowned for its outstanding resistance to corrosion, aluminum emerges as the perfect material for deployment in environments that harbor chemicals. Its ability to withstand numerous acids, alkalis, and solvents guarantees the longevity and sturdiness of the coils. Moreover, aluminum coils boast remarkable heat conductivity, enabling efficient heat transfer throughout the chemical processing procedure. Their lightweight composition further facilitates hassle-free handling and installation. Collectively, aluminum coils emerge as a dependable option for chemical processing applications owing to their corrosion resistance, heat conductivity, and durability.

- Q: Can aluminum coils be used in automotive radiators?

- Yes, aluminum coils can be used in automotive radiators. In fact, aluminum is a popular choice for radiator construction due to its excellent heat transfer properties, lightweight nature, and corrosion resistance.

- Q: Are aluminum coils suitable for marine environments?

- Aluminum coils are suitable for marine environments due to their excellent corrosion resistance properties. Aluminum has a natural oxide layer that forms on its surface, providing a protective barrier against saltwater corrosion. This makes aluminum coils highly resistant to rust and deterioration caused by exposure to marine conditions. Moreover, aluminum is lightweight, making it a preferred choice for marine applications where weight reduction is essential. Additionally, aluminum coils offer good thermal conductivity, which is beneficial for dissipating heat in marine cooling systems. Overall, aluminum coils are a reliable and durable choice for marine environments, ensuring long-lasting performance and minimal maintenance requirements.

- Q: Are aluminum coils suitable for electrical transformers?

- Electrical transformers can indeed utilize aluminum coils. Aluminum, being a lightweight and cost-effective material, presents numerous advantages when it comes to transformer construction. Its electrical conductivity is outstanding, comparable to that of copper, which ensures efficient power transfer. Moreover, aluminum coils exhibit lower resistance than their copper counterparts, thereby reducing power losses and enhancing energy efficiency. The utilization of aluminum coils also aids in weight reduction, resulting in easier handling and transportation. Nonetheless, due to their marginally lower conductivity, aluminum coils necessitate larger cross-sections compared to copper coils. Consequently, transformers employing aluminum coils may exhibit a slightly larger size. Nevertheless, overall, aluminum coils serve as a viable and extensively employed substitute for copper coils in electrical transformers, offering cost savings, high conductivity, and improved energy efficiency.

- Q: Can aluminum coils be used in heat exchanger fins?

- Yes, aluminum coils can be used in heat exchanger fins. Aluminum is a popular choice for heat exchangers due to its excellent thermal conductivity, lightweight nature, and corrosion resistance. The use of aluminum coils in heat exchanger fins allows for efficient transfer of heat between two fluids, making it an ideal material for this application. Additionally, aluminum coils can be easily formed into various fin shapes, providing flexibility in design and maximizing the surface area for heat transfer. Overall, aluminum coils are commonly used in heat exchanger fins to enhance heat transfer efficiency and improve the overall performance of the heat exchanger system.

- Q: What are the potential health risks associated with working with aluminum coils?

- Individuals who work with aluminum coils may face certain health hazards. One of the main concerns is the possibility of being exposed to aluminum dust or fumes. Inhaling these particles can lead to respiratory problems like coughing, difficulty breathing, and symptoms similar to asthma. Prolonged or excessive exposure to aluminum dust can even result in a condition called aluminum pneumoconiosis, which causes lung scarring and impairs breathing. Moreover, aluminum is a substance that is toxic to the nervous system, and prolonged exposure to high levels of aluminum can lead to neurological disorders. Some studies have suggested a potential connection between aluminum exposure and conditions like Alzheimer's disease, although further research is needed to establish a definitive cause-and-effect relationship. Another health risk associated with working with aluminum coils is the possibility of skin irritation. Direct contact with aluminum can cause contact dermatitis, which manifests as redness, itching, and inflammation of the skin. To minimize the risk, it is crucial for workers to take necessary precautions such as wearing protective clothing and gloves. Additionally, working with aluminum coils may involve the use of chemicals like lubricants, solvents, or cleaners, which also pose health risks. These chemicals can cause skin and respiratory irritation, and in some cases, they may lead to long-term health issues such as organ damage or cancer. In conclusion, while there are many advantages to working with aluminum coils, it is vital to be aware of the potential health hazards involved. Employers and workers should take appropriate safety measures, including wearing personal protective equipment, implementing effective ventilation systems, and following best practices to minimize exposure and mitigate any potential health risks. Regular monitoring and medical check-ups are also advisable for individuals regularly exposed to aluminum coils to ensure early detection and prevention of any adverse health effects.

- Q: What are the different types of aluminum coils?

- There are several different types of aluminum coils, including plain aluminum coils, painted aluminum coils, embossed aluminum coils, and coated aluminum coils. Each type has specific properties and uses, making them suitable for different applications in various industries.

Send your message to us

102 Aluminum Coil for Interior Wall System - Brushed Coating Washington

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords