Brushed Aluminum Sheets for Mobile Phone Shell and Camper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Brushed Aluminium Sheet for Mobile Phone Shell

l Product Information

1) alloy number 1050 1060 1100 1200 3003.

2) temper available O H12 H14 H16 H18.

3) application: cookware utensil and basin.

4) thickness: 0.2-6.0mm.(+/-0.02mm)

5) diameter: 120-1360mm.(+/-0.5mm)

6) production treatment: cold rolled or hot rolled.

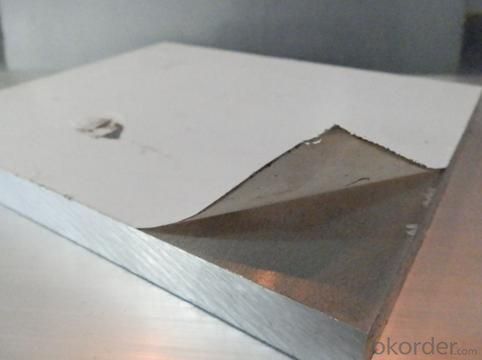

7) surface appearance: flat clean surface no whole, scratch, oil dirty and oxidation.

8) cutting edge: neat cutting edge no burrs.

Chemistry Composition & Mechanical Properties

l Packaging & Delivery

Packaging detail: Sea Worthy Wooden pallet

Delivery detail: About 25 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium Products have been our featured products. We have specialized in aluminium products for about a decade and have sold our good quality aluminium products to the worldwide.

l CNBM World Wide

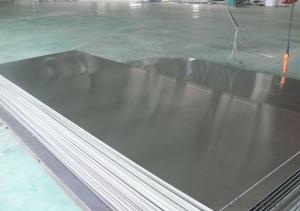

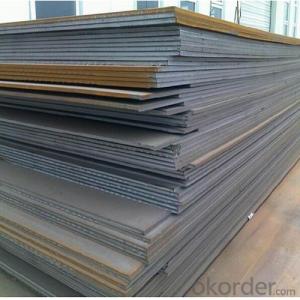

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q: What are the different types of surface treatments available for anodized aluminum sheets?

- There are several different types of surface treatments available for anodized aluminum sheets. These treatments can enhance the appearance, durability, and functionality of the aluminum surface. 1. Brushed Finish: This treatment involves brushing the surface of the aluminum sheet with abrasive materials to create a pattern of parallel lines. It gives the sheet a matte appearance and helps to hide scratches and fingerprints. 2. Mirror Finish: In this treatment, the aluminum sheet is polished to a high gloss finish, creating a mirror-like reflection. This finish is commonly used in decorative applications and gives a sleek and modern look to the aluminum surface. 3. Etched Finish: Etching involves using chemicals or abrasive materials to remove a thin layer of the anodized coating from the aluminum surface. This creates a textured or patterned design on the sheet. Etching can be done in various depths and designs, allowing for customization and unique aesthetics. 4. Powder Coating: Powder coating is a popular surface treatment where a dry powder is electrostatically applied to the anodized aluminum sheet and then cured under heat. This creates a durable and resistant coating that can be customized in terms of color, texture, and finish. 5. Satin Finish: Satin finish involves sanding the aluminum sheet with fine grit sandpaper to create a smooth, brushed appearance. It provides a subdued and elegant look to the aluminum surface. 6. Mechanical Finishes: Mechanical finishes include various techniques like polishing, buffing, or grinding to achieve different surface textures and finishes. These finishes can range from smooth and glossy to rugged and textured, depending on the desired effect. 7. Chemical Treatments: Chemical treatments such as anodizing, chromating, or chemical brightening can be used to enhance the corrosion resistance, color, and overall appearance of the aluminum sheet. These treatments can also improve the adhesion of paints or adhesives to the surface. It is important to note that the availability of these surface treatments may vary depending on the manufacturer and specific requirements. It is recommended to consult with the supplier or manufacturer to determine the most suitable surface treatment for your application.

- Q: I had this mandarin orange can. I filled the can with water. Four days later, there are quarter inch thick rust cakes on the inside of the can. Since I assume the can is aluminum, are these cakes aluminum oxide? If so, is it flammable and/or dangerous?

- Aluminum oxide is white and powdery in texture. It also takes a bit longer for aluminum to oxidize than iron, so I don't think you could have cakes of aluminum oxide in 4 days. If the cakes you are describing are reddish in color, then no, it is NOT aluminum oxide. It is good old fashioned ferric oxide- rust from iron.

- Q: the aluminium pull tabs are in a jucy juice bottle

- So saving pull tabs isn't a complete waste of time. But let's make one thing clear: *there's nothing special about pull tabs*. You'd save yourself a heap o' trouble and make a lot more money if you recycled the whole can. The Reynolds and kidney foundation people have tried to get that point across with a poster showing a red Ghost busters-type slash through a cartoon of someone trying to detach a pull tab from a can. The headline says, Keep Tabs on Your Cans. But the public hasn't gotten the message. Supposedly responsible people -- e.g., the honchos at your school -- will organize pull tab collection drives without even bothering to get the whole story. Urban legends expert Jan Brunvand reports that in 1989 a Minneapolis VFW post organized a pull tab collection drive for the local Ronald McDonald House. When Brunvand asked the organizers why they didn't tell people to save whole cans, they lamely replied that there were hygiene problems and that people liked mailing in the tabs, even though the postage often exceeded the value of the aluminum. In other words, it's not important to *do* good as long as people *feel* good. Sometimes I don't think we have enough common sense in this country to fill a teacup.

- Q: What are the different bending methods for aluminum sheets?

- Some of the different bending methods for aluminum sheets include air bending, bottom bending, coining, and rotary bending.

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- Is it pure Aluminum ? or an Alloy of some kind ? Are you heating the aluminum in a Steel Crucible ( bowl or spoon ) of which it will absorb much of the heat and it will be difficult to achieve the proper temp for the alum to melt. Is the Flame constant, No drafts to waver the flame off Target, In theory, the aluminum should melt if held long enough by itself over a large candle flame by tongs, also, How thick is the aluminum you are trying to melt? just trying to help, I'm no expert, but thought i'd give this a shot. Good Luck Color tells us about the temperature of a candle flame. The outer core of the candle flame is light blue -- 1670 K (1400 °C). That is the hottest part of the flame. The color inside the flame becomes yellow, orange and finally red. The further you reach to the center of the flame, the lower the temperature will be. The red portion is around 1070 K (800 °C).

- Q: What is the final concentration of aluminum cation?

- You have to be able to determine the number of moles of Al+3 that each solution contributes to the final solution: 1. aluminum chloride: AlCl3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0431 L x 0.279 M = 0.0120 mol AlCl3 in solution When the AlCl3 in placed in the water, it dissociates to form the following ions: AlCl3 -- Al+3 + 3Cl- So for every one mole of AlCl3 placed in the water, one mole of aluminum ions will dissociate. Therefore, since we have 0.0120 mole of AlCl3 in the solution, that means that the aluminum chloride will contribute 0.0120 Al+3 ions to the final solution. 2. Aluminum sulfate: Al2(SO4)3 Multiply the volume (in L) by the molarity to determine the number of moles of each compound dissolved in solution. 0.0146 L x 0.464 M = 0.00677 mol Al2(SO4)3 in solution When the Al2(SO4)3 in placed in the water, it dissociates to form the following ions: Al2(SO4)3 -- 2Al+3 + 3(SO4)-2 So for every one mole of Al2(SO4)3 placed in the water, two mole of aluminum ions will dissociate. Use the mole ratios of the dissociation reaction to determine the number of moles of Al+3 ions that the aluminum sulfate contributes to the solution. 0.00677 mol Al2(SO4)3 x (2 mol Al+3 ions / 1 mol Al2(SO4)3) = 0.01354 mol Al+3 ions Therefore, the total number of Al+3 ions in solution is the sum: 0.01354 + 0.0120 = 0.02554 mol Al+3 ions The last piece of information needed to determine the concentration of the final solution is the volume of the final solution. Since the two volumes were mixed, the volume of the final solution will be the sum of the two solutions. 0.0431 L + 0.0146 L = 0.0577 L Therefore, to calculate molarity: Molarity = moles of solute / liters of solution Molarity = 0.02554 mol / 0.0577 L = 0.443 M Al+3

- Q: I need to make an aluminum cylinder out of 1/8 6061 plate and tube. I don't have a TIG setup and was considering using Bernzomatic aluminum soldering rods. The cylinder will be pressurized from 20-60 psi. Assuming a clean job, is this pressure ok? How much pressure can the joint take? Also, although the solder does not need flux, should i use it anyway?

- Whether that weld will be OK depends on the diameter of the cylinder. The force on the weld will be equal to the operating pressure time the radius of the cylinder, with the wall opposite the weld have an equal force. Divide that force by the thickness of the weld to figure the stress. You want to have a safety factor of about 3. As the Bernzomatic has either a brass or aluminum head, which would melt at the temperatures which are required for true welding (melting metals so that they flow together), you will be performing brazing with a Bernzomatic. I cannot comment on the strength of the brazing bond. The thickness of the brazing metal deposit depends on the strength of the brazing alloy, which I also cannot comment on. 6061 will melt at 1206°, which you will not approach with the Bernzo kit. A blowout of a metal cylinder at 60 psi could be pretty ugly. I suggest that you befriend someone who has a TIG welder and get their help. A properly welded 1/8 thick cylinder could handle about 660 psi with no problem. If you create a lap joint, using an outer strip of aluminum, and then band your cylinder with stainless steel hose clamps, you will be relying upon the brazing only to provide a gas seal. The strength would come from the hose clamps. You still need to do some calculation on forces involved. A 1/2 wide stainless hose clamp will probably hold back about 240 lb. of force with a comfortable margin of safety.

- Q: What are the standard sizes and availability of aluminum sheets in the market?

- The standard sizes and availability of aluminum sheets in the market can vary depending on the location and specific requirements. However, there are some commonly available sizes that can generally be found in most markets. In terms of thickness, aluminum sheets are commonly available in 0.02 to 0.2 inches (0.5 to 5 millimeters) thickness range. Thinner sheets (0.02 to 0.06 inches) are often used for lightweight applications such as signage or crafts, while thicker sheets (0.1 to 0.2 inches) are typically used for more heavy-duty applications like construction or industrial purposes. Regarding width and length, standard aluminum sheet sizes are often offered in 4 feet by 8 feet (48 inches by 96 inches) or 4 feet by 12 feet (48 inches by 144 inches). These dimensions are widely available and suitable for various applications. However, it's important to note that custom sizes can also be ordered or cut from larger sheets to meet specific project requirements. Availability of aluminum sheets can be found in various locations, including local hardware stores, metal suppliers, and online marketplaces. It is always recommended to check with local suppliers or conduct online research to determine the specific sizes and availability in your area. Additionally, different grades or alloys of aluminum may have varying availability, so it's essential to consider the specific requirements of your project when sourcing aluminum sheets.

- Q: Are aluminum sheets suitable for insulation purposes?

- Yes, aluminum sheets are suitable for insulation purposes. Aluminum is a highly reflective material that can effectively block the transfer of heat, making it an excellent choice for insulation. It has a low emissivity value, meaning that it reflects heat radiation rather than absorbing it. This property helps to maintain a consistent temperature within a space, reducing the need for heating or cooling. Additionally, aluminum sheets are lightweight, easy to install, and resistant to moisture, making them a practical option for insulation in various applications such as attics, walls, floors, and HVAC systems.

- Q: What are the different surface treatments available for aluminum sheets?

- Some of the different surface treatments available for aluminum sheets include anodizing, painting, powder coating, and polishing. Anodizing provides a durable and corrosion-resistant finish by creating an oxide layer on the surface of the aluminum. Painting involves applying a coat of paint to the sheet, which can provide both protection and aesthetic appeal. Powder coating is a process where a dry powder is applied to the aluminum and then heated, creating a durable and vibrant finish. Polishing involves buffing the surface of the aluminum to create a smooth and reflective finish.

Send your message to us

Brushed Aluminum Sheets for Mobile Phone Shell and Camper

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords