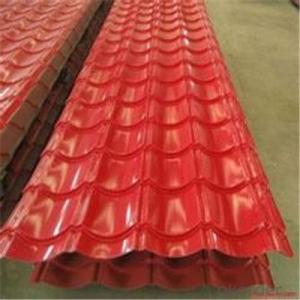

Zinc Aluminum Roofing Sheets - Aluminium Chequered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Aluminum sheet/coil (DC line) 5000series

1) Alloy:5005,5052,5083,5251,5754

2) Temper: Various status

3) Thickness:0.3-150mm

Aluminum sheet/coil (CC And DC )

1) Alloy: 1000series, 3000series, 5000series

2) Temper: Various status

3) Thickness:0.3-350mm

4) Width:300-1600mm

5) Weight: 2.5-5.0 tons per coil

6) Length: Under9500mm/ Coil

7) Inner Diameter: 505mm,605mm

8) Dimensions and weight can be produced according to clients' specifications.

9) Packing: Export standard, wooden pallet.

10) Delivery time: 30 days

11) Minimum order quantity: 5 tons per size.

12) The term of payment: T/T, irrevocable L/C at sight.

13) Surface: Mill finish

14) Origin: China

Thickness Specifications: 0.3mm---150mm

Width Specifications: 300mm---1950 mm

Length Specifications: Under9500mm/ Coil

- Q: I was hoping someone could explain aluminum corrosion with degreasers and cleaning formulas for automotive cleaning. This starts with, where is this aluminum (wheels)?, what types of cleaners?, do cleaners cause corrosion? Any insights would be appreciated.

- stick with an automotive brand cleaner most wheels are clearcoated to prtect the finish. I use 50/50 water and simple green to clean wheels and ive been detailing 20+ years

- Q: What is the maximum temperature resistance of aluminum sheets?

- The maximum temperature resistance of aluminum sheets is typically around 600 degrees Fahrenheit (315 degrees Celsius). However, this can vary depending on various factors such as the alloy composition, thickness, and treatment of the aluminum sheets. It is always important to consult the manufacturer's specifications or obtain professional advice when considering the use of aluminum sheets in high-temperature applications.

- Q: Can aluminum sheets be anodized in different finishes?

- Yes, aluminum sheets can be anodized in different finishes. Anodizing is an electrochemical process that enhances the natural oxide layer on aluminum, making it thicker and more durable. This process can be customized to achieve various finishes such as clear, colored, or even textured surfaces. The type of finish depends on factors like the alloy composition, anodizing method, and the desired appearance. Anodized aluminum sheets are widely used in various industries including architecture, automotive, and electronics due to their corrosion resistance, aesthetic appeal, and ability to retain color over time.

- Q: Are aluminum sheets conductive?

- Yes, aluminum sheets are conductive. Aluminum is a metal and has a high electrical conductivity. This means that electricity can easily flow through aluminum sheets, allowing them to be used in various applications where conductivity is required, such as in electrical wiring, power transmission lines, and electronic devices.

- Q: Can aluminum sheets be used for reflective insulation?

- Yes, aluminum sheets can be used for reflective insulation. Aluminum is highly reflective and has good thermal conductivity, making it an excellent choice for reflecting heat and reducing heat transfer. When used as insulation, aluminum sheets can reflect heat away from the surface, preventing it from entering or escaping the desired area. This can help in maintaining a comfortable temperature inside a building or protecting sensitive equipment from extreme heat or cold. Additionally, aluminum sheets are lightweight and easy to install, making them a popular choice for reflective insulation applications.

- Q: Can the aluminum sheets be used for manufacturing power distribution systems?

- Yes, aluminum sheets can be used for manufacturing power distribution systems. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight, and cost-effectiveness. It is commonly used for manufacturing busbars, which are the main component of power distribution systems. Aluminum sheets can be easily fabricated and formed into the desired shape for busbars, allowing for efficient power transmission and distribution. Additionally, aluminum has good corrosion resistance, making it suitable for outdoor applications. However, it is important to ensure that the aluminum sheets meet the required electrical and mechanical specifications for power distribution systems to ensure safe and reliable operation.

- Q: Can the aluminum sheets be used in the construction industry?

- Yes, aluminum sheets can be used in the construction industry. Aluminum is lightweight, corrosion-resistant, and has high strength-to-weight ratio, making it suitable for various construction applications such as roofing, cladding, windows, and doors.

- Q: What is the density of aluminum sheets?

- The density of aluminum sheets can vary depending on the specific alloy and thickness of the sheet. However, on average, the density of aluminum sheets falls between 2.6 to 2.8 grams per cubic centimeter (g/cm³). It is important to note that this value may change slightly based on the specific manufacturing process and any additional coatings or treatments applied to the sheets.

- Q: What are the benefits of using aluminum sheets?

- Using aluminum sheets in various applications offers several advantages. Firstly, aluminum sheets are lightweight, which makes them easy to handle and transport. This is particularly beneficial in industries like aerospace, automotive, and construction, where reducing weight is crucial for better fuel efficiency and overall performance. Secondly, aluminum sheets provide excellent resistance to corrosion. Unlike other metals, aluminum naturally develops a protective oxide layer when exposed to air, preventing further corrosion and enhancing durability. This makes aluminum sheets highly suitable for outdoor applications or in environments with high humidity or corrosive substances. Another advantage of aluminum sheets is their high strength-to-weight ratio. Aluminum is known for its exceptional strength, allowing it to withstand heavy loads or extreme conditions without compromising its structural integrity. This makes it an ideal choice for constructing lightweight yet sturdy structures, such as building facades, vehicles, or industrial equipment. Additionally, aluminum sheets are highly malleable and ductile, meaning they can easily be formed into various shapes and sizes. This flexibility allows for intricate designs and customization, making aluminum sheets highly versatile and adaptable to different manufacturing processes or project requirements. Furthermore, aluminum is a sustainable and environmentally friendly material. It is completely recyclable, meaning it can be reused repeatedly without losing its properties or quality. Recycling aluminum requires significantly less energy compared to primary aluminum production, resulting in reduced carbon emissions and a smaller environmental footprint. Lastly, aluminum sheets exhibit excellent thermal and electrical conductivity properties. This makes them suitable for applications that require efficient heat transfer or electrical conductivity, such as heat exchangers, solar panels, or electrical wires. In conclusion, the benefits of using aluminum sheets include their lightweight nature, corrosion resistance, high strength-to-weight ratio, malleability, sustainability, and excellent thermal and electrical conductivity. These advantages make aluminum sheets a popular choice in various industries, contributing to improved performance, cost-effectiveness, and environmental sustainability.

- Q: What are the different manufacturing methods for aluminum sheets?

- There are several different manufacturing methods for aluminum sheets, each with its own unique characteristics and applications. 1. Rolling: The most common method of manufacturing aluminum sheets is through rolling. In this process, large slabs of aluminum are passed through a series of rollers, which reduce the thickness of the slab and increase its length. This method can produce sheets with consistent thickness and excellent surface finish. 2. Extrusion: Extrusion is another method used to manufacture aluminum sheets. In this process, a heated billet of aluminum is forced through a die, resulting in a continuous length of sheet. Extrusion allows for complex shapes and profiles to be created, making it suitable for applications such as building construction and automotive components. 3. Casting: Casting involves pouring molten aluminum into a mold and allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or sheets with specific alloy compositions. Casting can offer unique properties and is commonly used in industries such as aerospace and defense. 4. Cladding: Cladding is a process where a thin layer of aluminum is bonded to another material, such as steel or composite materials. This method combines the desirable properties of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets are commonly used in construction, transportation, and electrical industries. 5. Powder metallurgy: Powder metallurgy involves the formation of aluminum sheets from powdered aluminum particles. The powder is compacted into a desired shape and then sintered at high temperatures to fuse the particles together. This method is used for producing complex shapes and can provide improved mechanical properties. Each manufacturing method for aluminum sheets has its own advantages and disadvantages, depending on the desired properties, application, and cost considerations. Therefore, it is important to carefully select the most appropriate method based on the specific requirements of the project.

Send your message to us

Zinc Aluminum Roofing Sheets - Aluminium Chequered Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords