Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

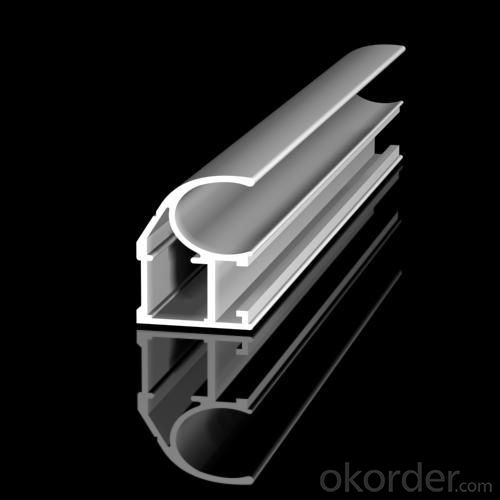

Structure of Aluminium Anodizing for Construction Application Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Anodizing for Construction Application:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Anodizing for Construction Application:

Aluminium Anodizing for Construction Application Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ Aluminium Cast Slab not Alloyed in Coil Form:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: Xi'an XAC aluminum sales site.

- How to choose the industrial aluminum profiles, this problem for the just contact with industrial aluminum profile friends, is really a serious problem to consider.That selection of industrial aluminum manufacturers is not good, money, goods is not good, he can give you redo is OK, but also take time; meet industrial aluminum manufacturers some black, and you may be wrangling, that egg pain.

- Q: What are the different shapes and profiles available for aluminum profiles?

- There are various shapes and profiles available for aluminum profiles, including but not limited to T-shape, L-shape, square, rectangular, round, and oval. These profiles can have different dimensions and thicknesses to suit specific applications and design requirements.

- Q: This question asks for methods to protect aluminum profiles from damage during the installation process.

- <p>To prevent damage to aluminum profiles during installation, follow these guidelines: Use protective gloves and tools to avoid scratching the surface. Handle the profiles gently to prevent bending or denting. Ensure the work area is clean and free of debris that could damage the profiles. Apply protective films or tapes to vulnerable areas if necessary. Use the correct tools for cutting and drilling to avoid damaging the profile edges. Keep the profiles dry and away from corrosive substances. Always follow the manufacturer's guidelines for installation to ensure proper handling and protection of the aluminum profiles.</p>

- Q: Are aluminum profiles suitable for automotive body panels?

- Automotive body panels can indeed be made from aluminum profiles. Aluminum, a lightweight and durable material, offers numerous advantages over traditional steel panels. By reducing the weight of the vehicle, aluminum contributes to improved fuel efficiency, performance, and lower emissions. Additionally, aluminum panels boast exceptional corrosion resistance, thereby extending the lifespan of the vehicle. Furthermore, aluminum's high moldability enables the creation of intricate shapes, perfectly suited for the aerodynamic designs demanded in contemporary automotive styling. Moreover, aluminum aligns with the industry's increasing emphasis on sustainability as it is recyclable. It's worth noting, however, that specialized repair techniques may be necessary for aluminum panels, and their initial manufacturing cost can be higher than that of steel. Nonetheless, the benefits of using aluminum profiles for automotive body panels clearly outweigh the potential drawbacks, making them an ideal choice for modern vehicles.

- Q: Inquire if aluminum profiles can be recycled locally or regionally and how to find more information about it.

- <p>Yes, aluminum profiles can be recycled both locally and regionally. Recycling aluminum is an efficient process that conserves resources and energy. To find out more about local recycling options for aluminum profiles, you can: 1) Contact your local waste management or recycling center to inquire about their services. 2) Search online for recycling facilities in your region that specialize in aluminum. 3) Reach out to local metal scrapyards, as they often accept aluminum for recycling. 4) Check with local environmental agencies or non-profit organizations focused on recycling for guidance and resources.</p>

- Q: This question asks for guidance on selecting the appropriate size and shape of aluminum profiles for a specific application.

- <p>Choosing the right size and shape of an aluminum profile involves several steps. First, consider the load-bearing requirements and structural integrity needed for your application. Consult with engineering standards or use software that can simulate the stress and load on the profile. Second, consider the aesthetic and functional requirements, such as the profile's visibility and the need for specific features like slots or holes. Third, review the available profiles from suppliers, matching your needs with their offerings. Finally, prototype with the selected profile to ensure it meets all requirements before full-scale production. Always consult with aluminum profile manufacturers or suppliers for their expertise and recommendations.</p>

- Q: What do the 6063 and T5 represent in the aluminum profile 6063-T5?

- 5: the main alloying element is magnesium6: mainly add alloy elements for silicon and magnesium7: the main alloying elements are zinc and magnesium8: a new alloy that does not belong to the above alloy series2.2, second digits: an alloy that indicates the addition of alloying elements or impurities in the original alloy0: table alloy1: table original alloy by the first amendment2: table original alloy after second modifications2.3,

- Q: I have a product in the aluminum above the oxidation of 20 through the hole, that is so, good heat dissipation, I do not know, right, before oxidation, punching OK?

- This has nothing to do with the thermal conductivity. The processing of aluminum before oxidation is very good. After oxidation, the alumina is a dense layer of oxide to protect the internal aluminum from corrosion, and the drilling is easy to remove the oxide!

- Q: Are aluminum profiles energy-efficient?

- Certainly, aluminum profiles are regarded as energy-efficient. Being a highly conductive material, aluminum has the ability to efficiently transfer heat or cold. This characteristic enables aluminum profiles to offer outstanding thermal insulation, effectively reducing energy loss and ensuring a steady indoor temperature. Furthermore, aluminum profiles can be constructed with thermal breaks, which enhance their energy efficiency by diminishing heat transfer between the interior and exterior of a building. These attributes make aluminum profiles a favored option for windows, doors, and other building elements, as they actively contribute to energy conservation and mitigate a structure's overall carbon footprint.

Send your message to us

Bosch Aluminum Extrusion Profiles for Construction Application - Aluminum Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords