BNBM PUM Two-component Polyurethane Waterproof Coating

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

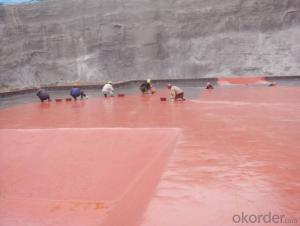

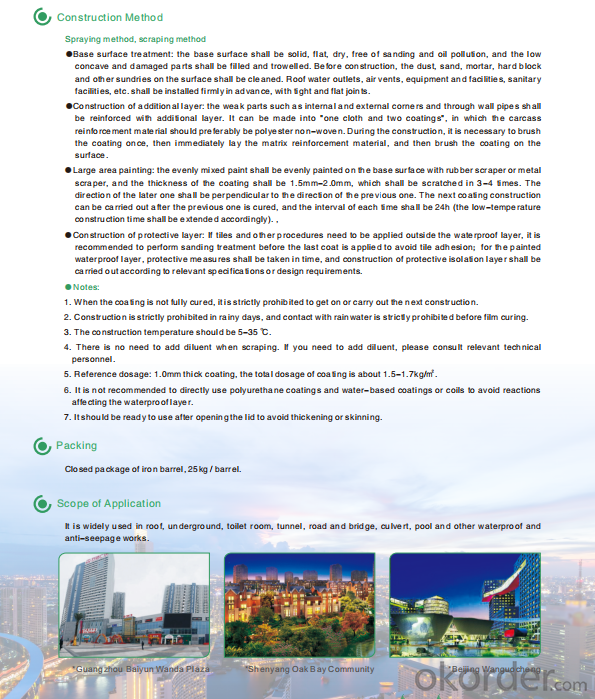

The two-component polyurethane waterproof coating is a film formed by reaction and solidification of two omponents A and B. Component A is a transparent to light yellow viscous liquid containing isocyanate end group generated by polymerization of polyether, polyisocyanate and other raw materials; Component B is a paste formed by mixing and processing of cross-linking agent, accelerator, toughener, tackifier, mould inhibitor, filler and pigment. When in use, A and B components are mixed in a certain proportion, stirred evenly, scraped and coated on the base surface, and after several hours of reaction curing, a waterproof coating with elasticity, toughness and durability is formed.

- Q: Bathroom first leveling or do waterproof, what is the difference

- Is the first water and then leveling. Home improvement toilet ground specific process practice: 1. The base layer, and which layer with the structural board, with cement mortar wipe. It is recommended to set the floor drain, the grassroots level should be flat and the direction of the leak to the slope. Against the wall and the root of the root should be wiped rounded.

- Q: What is the car waterproof sticker material?

- B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: What is the price of a waterproof window cover?

- 1, solid wood sets With the emphasis on environmental protection and economic conditions, some families choose solid window curtains, solid wood materials with environmental protection, beautiful, natural and other advantages, but also easy to deformation, thermal expansion and contraction, crack and other shortcomings. According to the final color of different, solid wood sets are divided into primary colors, color and color mixing. At present, more often solid wood materials are Pinus sylvestris, red pine, Qu Liu, Catalpa wood, and some valuable materials such as: beech, Phoebe, pear, rosewood and so on.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Your pores, the respiratory tract, the lungs, will be hurt, when young do not feel out, the consequences more powerful than smoking.

- Q: What are the key points and contents of the quality control of waterproof material?

- 3, infiltration of crystalline cement-based waterproof coating: on-site fraud is to use ordinary cement mixed with seafood powder (or 801 glue) so that the cement after the solidification of the color, it will not crack. Genuine infiltration of crystalline cement-based waterproof coating will have a hydrophobic effect that is the effect of lotus leaf water droplets (of course, this hydrophobic effect can not be too much, otherwise it will affect the next process of bonding).

- Q: What is the car material so that the car can be waterproof, in the rain will not leak in?

- ?B. printing, inkjet, photo, screen printing and other technology: refers to the computer will be vector or pixel images into the machine, the machine in accordance with the graphics inkjet or screen technology will color ink printing or screen in a transparent or white base film, And then through the cutting edge along the edge of the pattern; at present most of the manufacturing enterprises (such as motorcycles, electric bicycles, etc.) mass production car stickers are used screen printing process;

- Q: I would like to ask how to do in the warm water above,

- Rough housing or liquid with a good, airtight than the coil is good, all-pervasive, if there is a trachoma in the case of white do not see the white. If the building from the building if the first waterproof, finished product protection is a problem.

- Q: Developers have done waterproof, decoration house also have to do it

- Carbine water to remind you: the general finished house really done by the construction unit waterproofing, but we must know: First of all, developers for the rough housing waterproofing is more casual, may use the poor waterproof performance of the material, in the construction

- Q: Villa roof leakage what general reasons, what materials to remedy

- ??Note: Before the waterproofing and draining construction, the roof must be dry, because the roof of the water does not evaporate, the new waterproof layer will rise, the waterproof effect immediately invalid. Therefore, rainy days should not be construction, to wait until the sun will dry the water before construction.

Send your message to us

BNBM PUM Two-component Polyurethane Waterproof Coating

- Supplier:

BNBM Waterproof Co., Ltd

BNBM Waterproof Co., Ltd

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches