New Cement-based Osmotic Crystallization Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Cement-based Osmotic Crystallization Waterproofing Coating Description:

Cement-based permeable crystallization waterproofing material is a kind of inorganic gray pulverous, high efficient to protect environment waterproofing material. it has a special active substances, and it has an affinity to the water.It is a kind of catalyst.It uses the intrinsic to the chemical characteristics of cement concrete and porous, with water as the carrier and the help of osmosis, transmitting y filling in the pores of concrete,to catalyze the particacles in the concrete and the ingredients of no completely hydrating happening the hydration again. And it forms of insoluble tendrils crystal and combinewith concrete into one whole. So water and other liquids from any direction is blocked, to achieve permanet effect of waterproofing, moistureproofng and protecting steel bar and reinforcing concrete structure strength.

2.Main Features of Cement-based Osmotic Crystallization Waterproofing Coating:

•Can resist to leaking in long term and tolerate for high water pressure.

•Waterproofing effect is permanent, it has the extraordinary ability to repair itself

•Having heat resistance, moisture resistance, uv resistance, oxidation resistance, radiation resistance, resistance to carbonation.

•Spending low construction cost

•Convenient for construction.

3.Cement-based Osmotic Crystallization Waterproofing Coating Specification:

Flexural strength | ≥2.80(7d) | ≥3.50(28d) | ||

| compressive strength Mpa | ≥12.0(7d) | ≥ 18.0(28d) | ||

Wet base adhesive strength Mpa | ≥1.0 | |||

Permeability pressure(28d) | ≥0.8 | |||

| Osmotic pressure ratio(28d) | ≥20 |

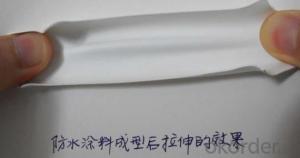

4.Cement-based Osmotic Crystallization Waterproofing Coating Images:

- Q: Eastern rainbow waterproof how to do

- Do not know where you use, waterproof as if a lot of materials. I know there are coiled, painted.

- Q: Find the construction steps for waterproof coatings

- 1, base surface treatment (1) roof structure After the completion of concrete pouring, should be repeated water compaction, so that the surface of the grass-roots level, the flatness with 2m to check the ruler, ruler and grass-roots gap of not more than 5 mm, and only allow gentle changes. (2) the base surface of the pores, rugged, honeycomb, gap, sand, etc., should be promptly treated, the base surface must be clean, no floating slurry, no water beads, no water; when the base surface appears more than 0.3 mm cracks , Should rush each 10 cm brushing 1 mm thick polyurethane coating waterproof layer, and then set the polyurethane cloth reinforcement layer, and finally brushing waterproof layer. (3) all the corners are used 5 × 5㎝ 1: 2.5 cement mortar for chamfering, the angle made R = 10 mm rounded corners.

- Q: Waterproof mortar expensive or dry mortar expensive

- Cationic neoprene latex is a polymer modified polymer anti-corrosion system. By the introduction of imported epoxy resin modified latex by adding the domestic neoprene emulsion and polyacrylate, synthetic rubber, various emulsifiers, modified latex and other components of the polymer latex.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- Do the cabinet can be in accordance with your size, finished cabinet moldy, which is not necessarily. You have to buy some of the Well

- Q: What material waterproofing can be mixed with cement sand

- Construction can also be used to produce waterproof pulp, waterproofing agent for the amount of cement 3 ‰ -4 ‰, the use of cement label not less than 32.5MPa.

- Q: Oriental rain rain waterproof how to

- Strict selection and the pursuit of excellence in product performance of the East Rainbow waterproof coating long-term waterproof material in the market leading the main reason. In order to test product performance, the East Rainbow company to the product to the plateau, desert, alpine, high temperature and other areas for testing.

- Q: How does the finished ventilator manufacturer waterproof?

- do not play any silicone and tape, to avoid the silicone tape aging caused by leakage hazards. Can be done once and for all.

- Q: Why should the use of high pressure perfusion waterproof plugging method

- High pressure grouting construction principle: is a special high-pressure grouting waterproof material through the high-pressure infusion equipment into the concrete crack structure extended until all the cracks (including the naked eye is difficult to meet) filled with water (water) with the cross-linking reaction, Release a large number of carbon dioxide gas, resulting in secondary pressure, high pressure and secondary pressure will be pressed into the elastomer and filled with all the gaps, to stop the purpose of leakage, it can be said that the best performance of plugging material,

- Q: Villa roof leakage what general reasons, what materials to remedy

- Second, if the roof is only the original did not do waterproof, only need to remove the leaky parts of 2 ~ 3cm deep after cleaning, you use asphalt irrigation, and now there is finished asphalt coating, such as sunny day when the treatment will basically not Leaked out. If there is a waterproof layer is too much trouble, to be around a range of waterproof tick, re-do waterproof, do when the attention and the original waterproof junction to do reinforcement layer. There are many ways to deal with leak detection, or to find some professional leak-proof companies to deal with this problem.

- Q: What is the difference between finished mortar and cement mortar?

- Finished mortar is good, easy to mix, is conducive to the improvement of masonry and work efficiency; cement sand waterproof, suitable for wall paste wall, wall light

Send your message to us

New Cement-based Osmotic Crystallization Waterproofing Coating

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 20000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords